Device for applying line for folding process on front cover before attachment to main body

A cover and main body technology, applied in the field of line devices, can solve problems such as poor production efficiency, labor and time consumption, and production efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

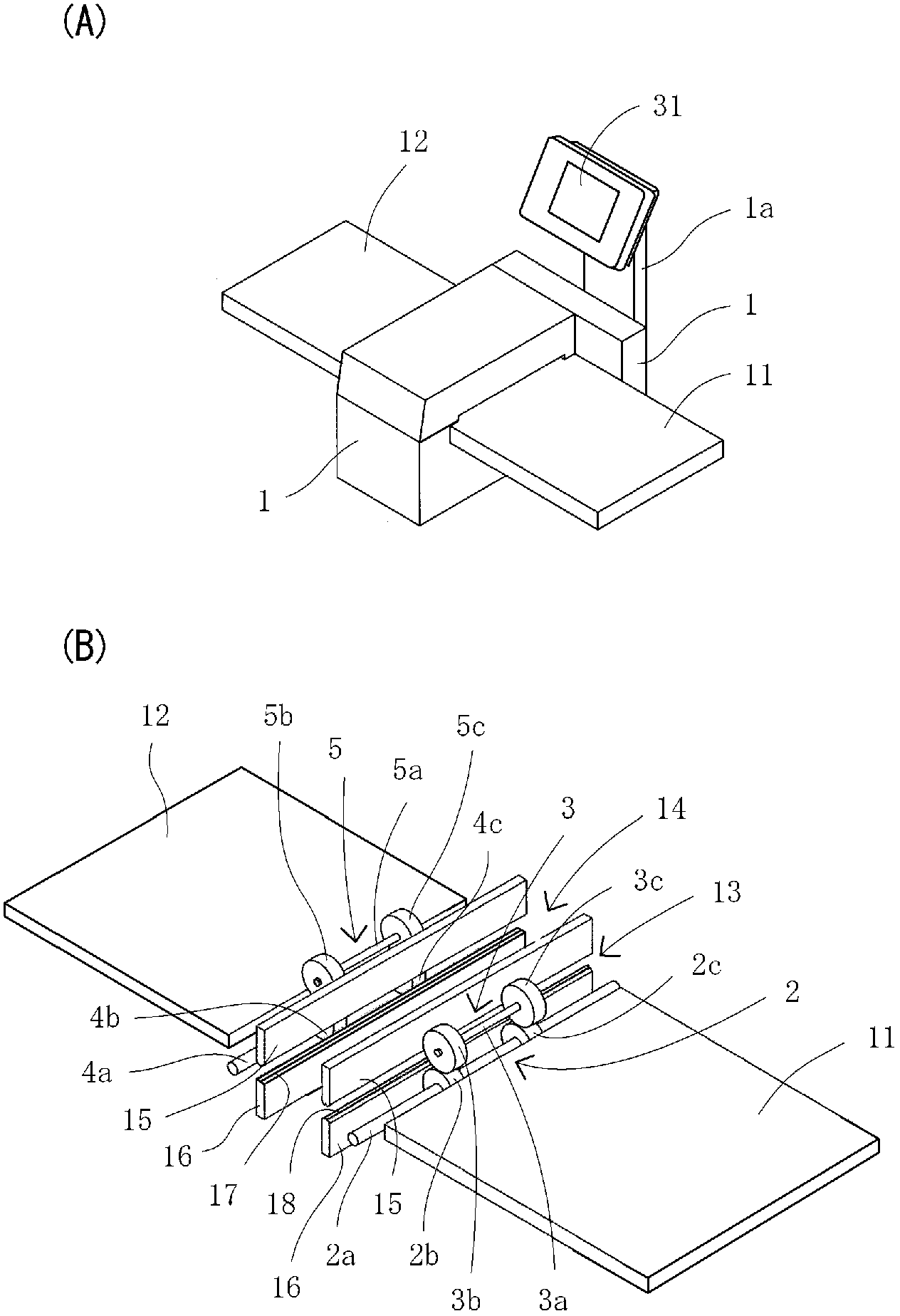

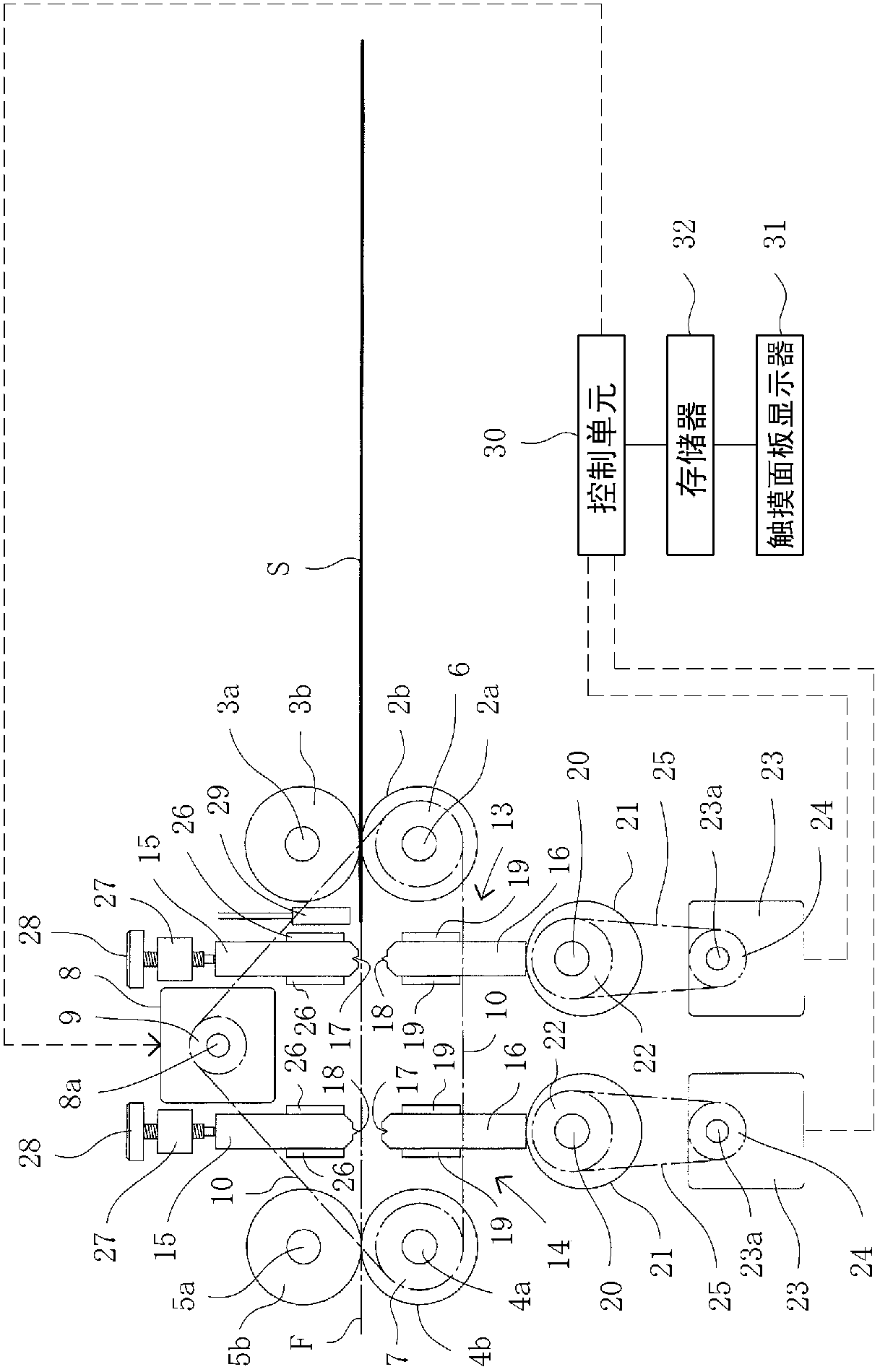

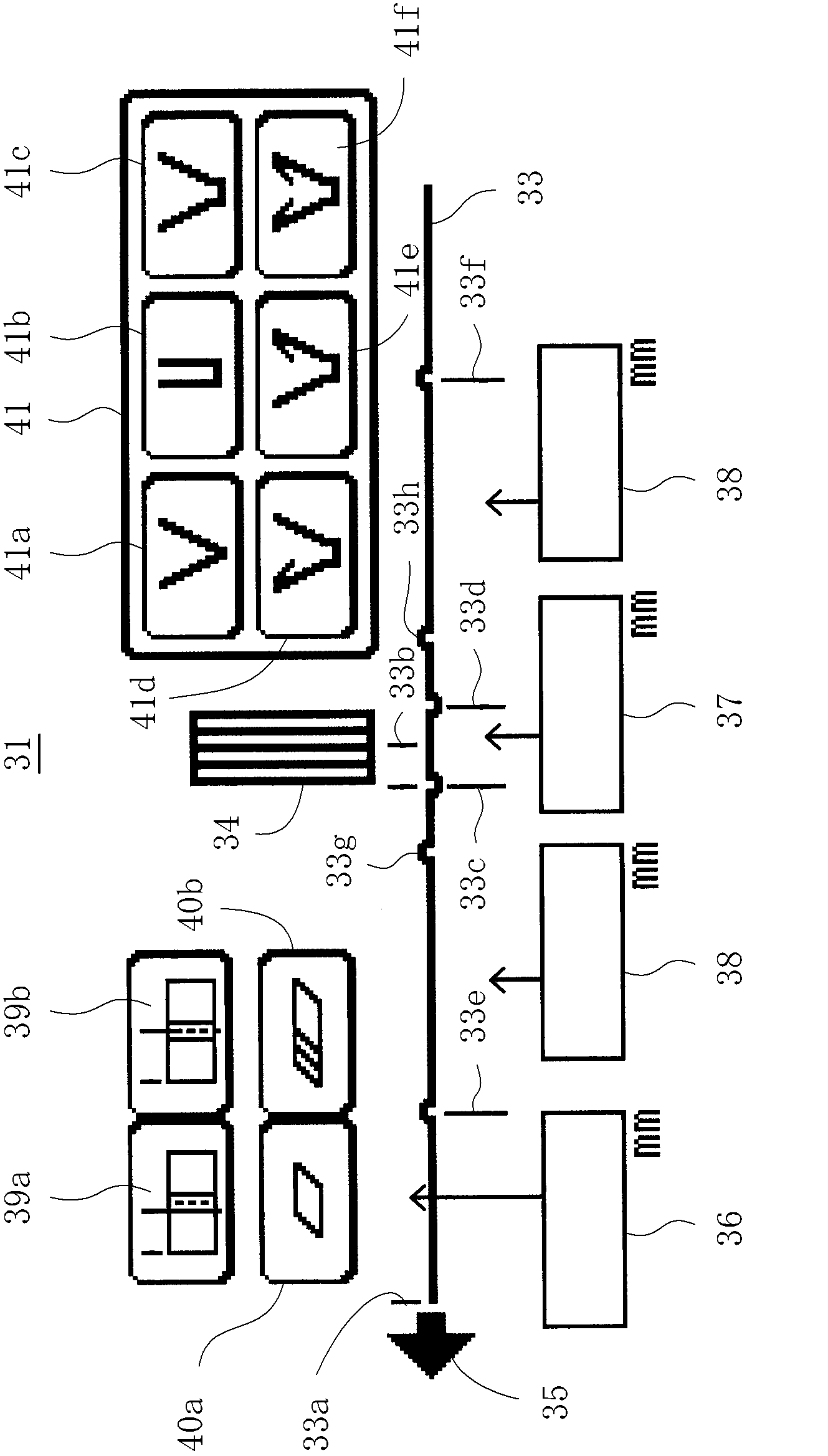

[0043] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 (A) is a perspective view of a device for adding lines for bending to the cover before the main body is pasted according to one embodiment of the present invention, figure 1 (B) is in figure 1 (A) is a perspective view of a state where the frame, the main body cover, and the driving mechanism are removed. and, figure 2 is a brief representation figure 1 A side view of the structure of the main part of the device shown.

[0044] When pasting the back forming area 50 of the cover S to the back of the main body, and then performing perfect binding of the cover S by bending, the device of the present invention is used. The cover S is, for example, Figure 6 As shown in (A) to (C), the cover S having the front cover forming region 51 and the back cover forming region 52 sandwiching the back forming region 50 on both sides, or Figure 6 As shown in (D) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com