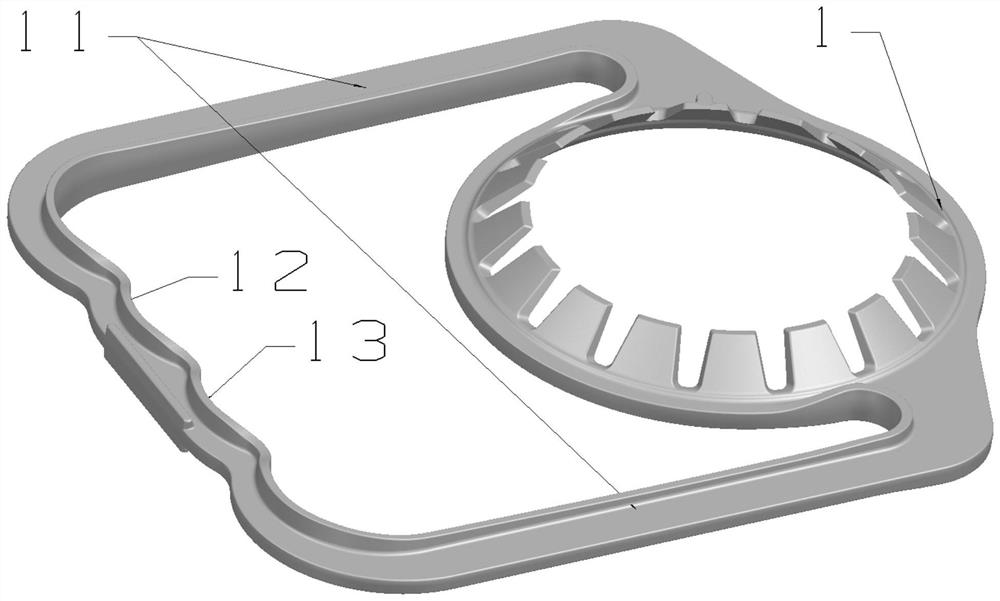

Opening type comfortable handle mold structure

A technology of opening type and mold, which is applied in household appliances, other household appliances, household components, etc., can solve problems such as inability to carry out actual production, and achieve the effect of reducing production efficiency and increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

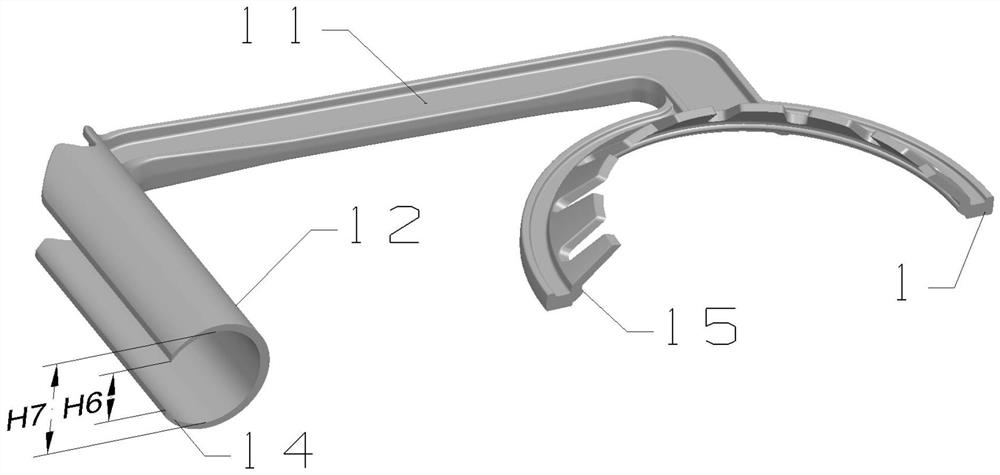

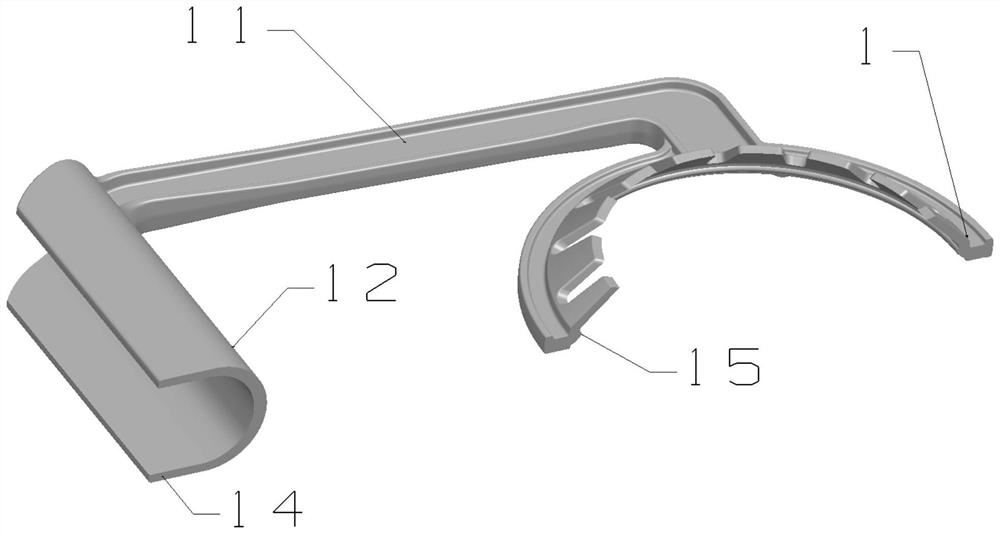

[0048] The first way ( Figure 4-Figure 10 ): the mandrel 4 is installed on the mold static plate group by the positioning mechanism 41, so that it can do a straight line from zero to the demoulding distance relative to the mold static cavity plate 3 ( Figure 5 ) or curved motion ( Figure 8 ), mandrel 4 can also rotate by positioning mechanism 41 ( Figure 7 ), the mandrel 4 will be pressed by the mold static cavity plate 3 and the mold dynamic cavity plate 2 under the mold clamping state, and the distance between the mandrel 4 and the mold static cavity plate 3 is zero ( Figure 4 ), between the mandrel 4 and the mold static cavity plate 3 and the mold dynamic cavity plate 2, the injection space of the annular opening 14 is formed ( Figure 4 ), after the product injection molding is completed, the mold starts to open the mold, and the auxiliary spring 5 is installed between the mandrel 4 and the mold static plate group to promote the mandrel 4 ( Figure 5 ), or use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com