Semiconductor device and cleaning system

A technology for semiconductors and equipment, applied in the field of semiconductor equipment and cleaning systems, can solve the problems of contaminating wafer products, scrapping products, contaminating semiconductor chambers, etc., without reducing the production efficiency of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

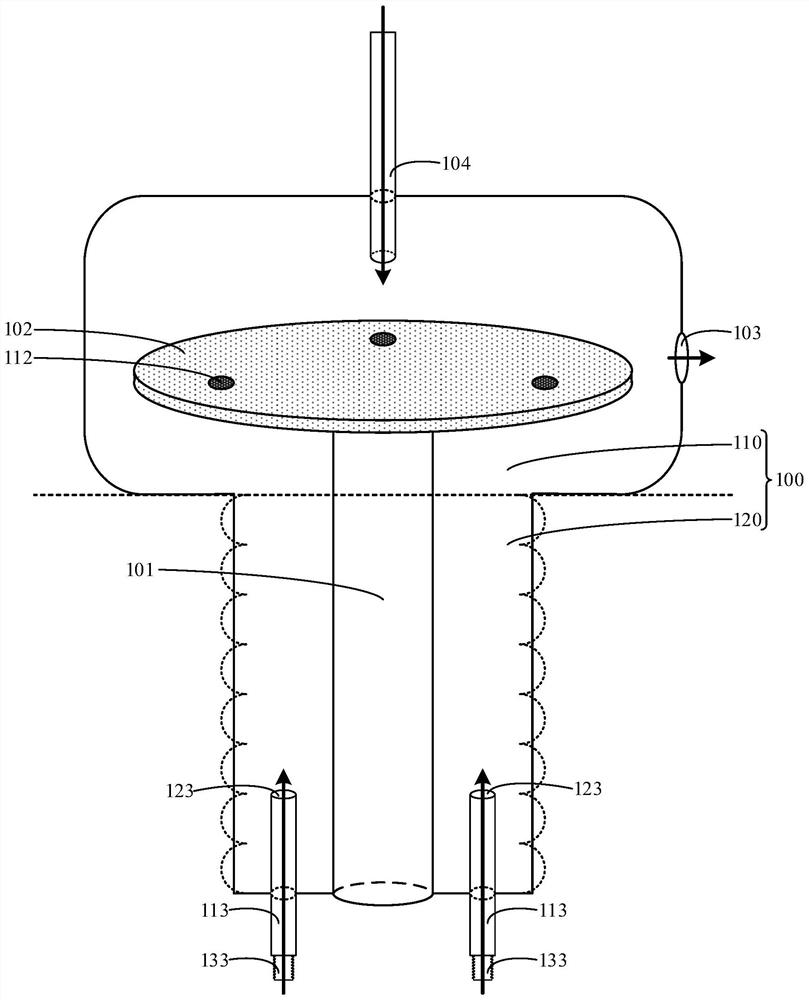

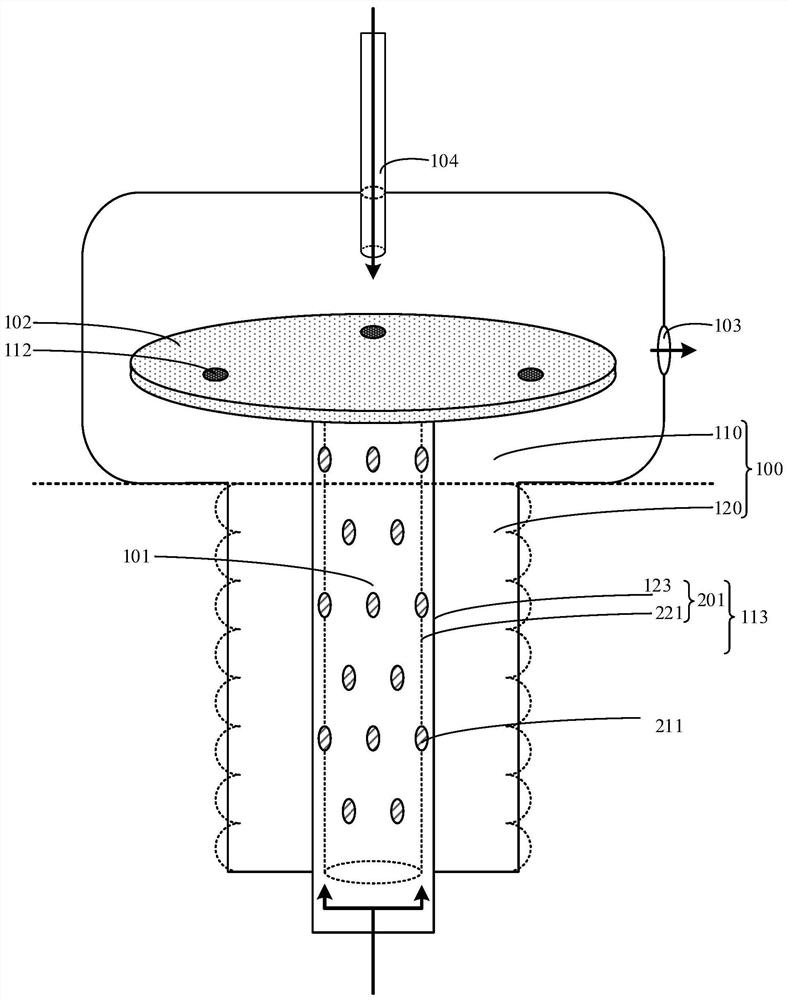

[0035] At present, the impurities accumulated at the bottom of the machine may rise up with the introduction of process gas during the production process, and fall on the wafer under the CVD process, contaminating the wafer product and directly causing the product to be scrapped.

[0036] In addition, impurities attached to the wafer may continue to contaminate other semiconductor chambers.

[0037] In order to ensure the deposition environment inside the CVD machine, the CVD machine is usually cleaned by the relevant staff during the maintenance of the CVD machine to remove the deposited impurities inside the machine. When the CVD machine performs the process for a long time , a large amount of impurities will accumulate at the bottom of the machine, which will shorten the maintenance cycle of the CVD machine, and the maintenance of the CVD machine will consume a lot of time, thereby reducing the production efficiency of wafer products.

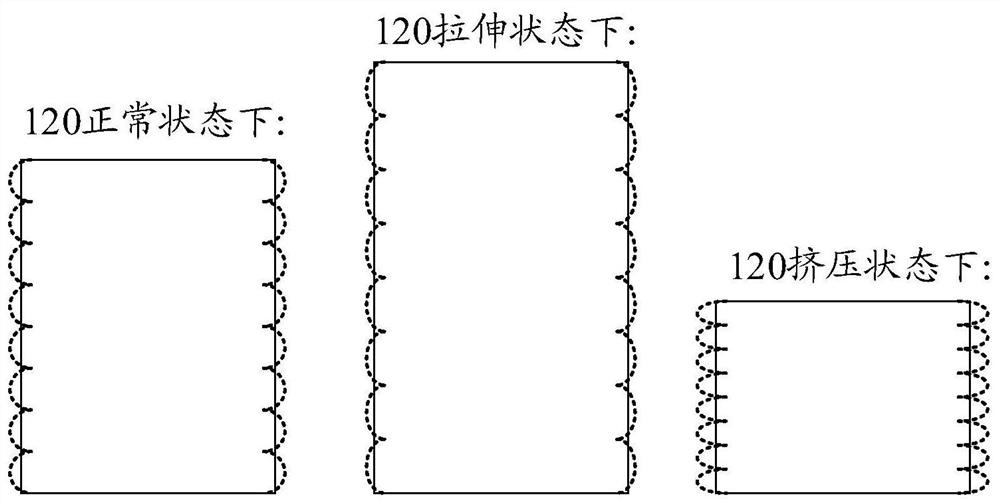

[0038] In order to solve the above pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com