Method for improving blast furnace smelting efficiency of high-aluminum iron ore with high-reactivity coke

A technology for high-reactivity coke and blast furnace smelting, which is applied in the field of iron and steel metallurgy and ironmaking, can solve the problems of not considering the effect of high-reaction coke and the production cost of high-alumina iron ore efficiency in blast furnace smelting, and achieves improved efficiency and comprehensive competition. power, reducing iron production costs, and improving economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

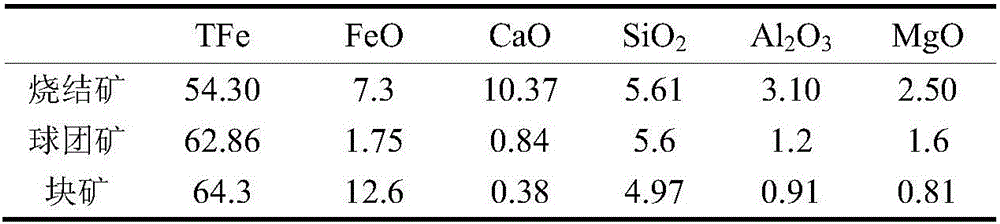

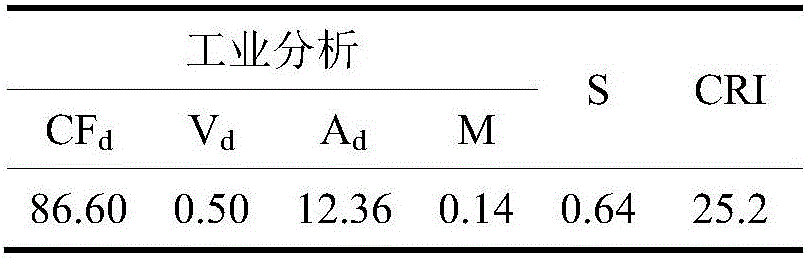

Embodiment 1

[0026] The high-reactivity coke (A) is made into diced coke with a size of 10mm, which is mixed with the iron-containing charge, and the mixing ratio of the coke is 2.5% of the weight of the iron-containing charge. The reduction and softening droplet test under load was used to simulate the reduction and softening droplet behavior of mixed ore / highly reactive coke dices in a blast furnace, and the test method was the same as in Comparative Example 1. The chemical composition of iron-containing raw materials (sinter, pellets, lump ore) is shown in Table 1, and the basic properties of high-reactivity coke (A) are shown in Table 3. The coke reactivity index CRI is 95%, and the wear resistance Intensity M 10 30%. The test results show that under this condition, the droplet performance index S of the charge is 47.22kPa·℃. Compared with the comparative example, the air permeability of the reflow process is significantly better. After analysis, about 90% of the highly reactive coke ...

Embodiment 2

[0030] The high-reactivity coke (A) is made into diced coke with a size of 10mm, which is mixed with the iron-containing charge, and the mixing ratio of the coke is 1.0% of the weight of the iron-containing charge. The reduction and softening droplet test under load was used to simulate the reduction and softening droplet behavior of mixed ore / highly reactive coke dices in a blast furnace, and the test method was the same as in Comparative Example 1. The chemical composition of iron-containing raw materials (sinter, pellets, lump ore) is shown in Table 1, and the basic properties of high-reactivity coke (A) are shown in Table 3. The coke reactivity index CRI is 95%, and the wear resistance Intensity M 10 30%. The test results show that under this condition, the droplet performance index S of the charge is 60.15kPa·℃, and the air permeability of the reflow process is better than that of the comparative example, but due to the reduction of the mixing amount, the degree of impro...

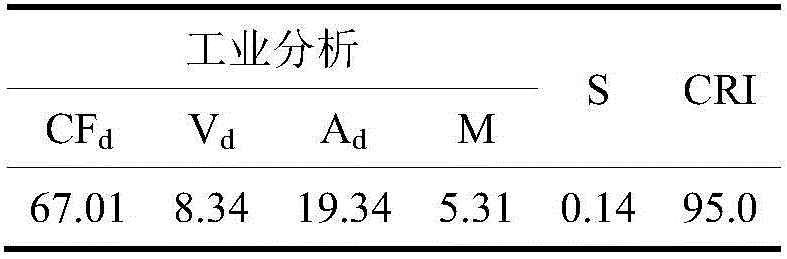

Embodiment 3

[0032] The high-reactivity coke (B) is made into diced coke with a size of 10 mm, which is mixed with the iron-containing charge, and the mixing ratio of the coke is 2.5% of the weight of the iron-containing charge. The reduction and softening droplet test under load was used to simulate the reduction and softening droplet behavior of mixed ore / highly reactive coke dices in a blast furnace, and the test method was the same as in Comparative Example 1. The chemical composition of iron-containing raw materials (sinter, pellets, lump ore) is shown in Table 1. The basic properties of highly reactive coke (B) are shown in Table 4. The coke reactivity index CRI is 65%. Intensity M 10 is 10.0%. The test results show that under this condition, the droplet performance index S of the charge is 70.30kPa·℃. Compared with the comparative example, the air permeability of the reflow process becomes better. Compared with Example 1, the improvement degree of air permeability is lower, and ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com