Clutch type high-power efficient mechanical torque converter

A high-power, clutch-type technology, applied in mechanical equipment, fluid transmission devices, belts/chains/gears, etc., can solve the problems of reducing the production efficiency of coal mines and increasing the volume of the reducer, so as to achieve the effect of not reducing the production efficiency of coal mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

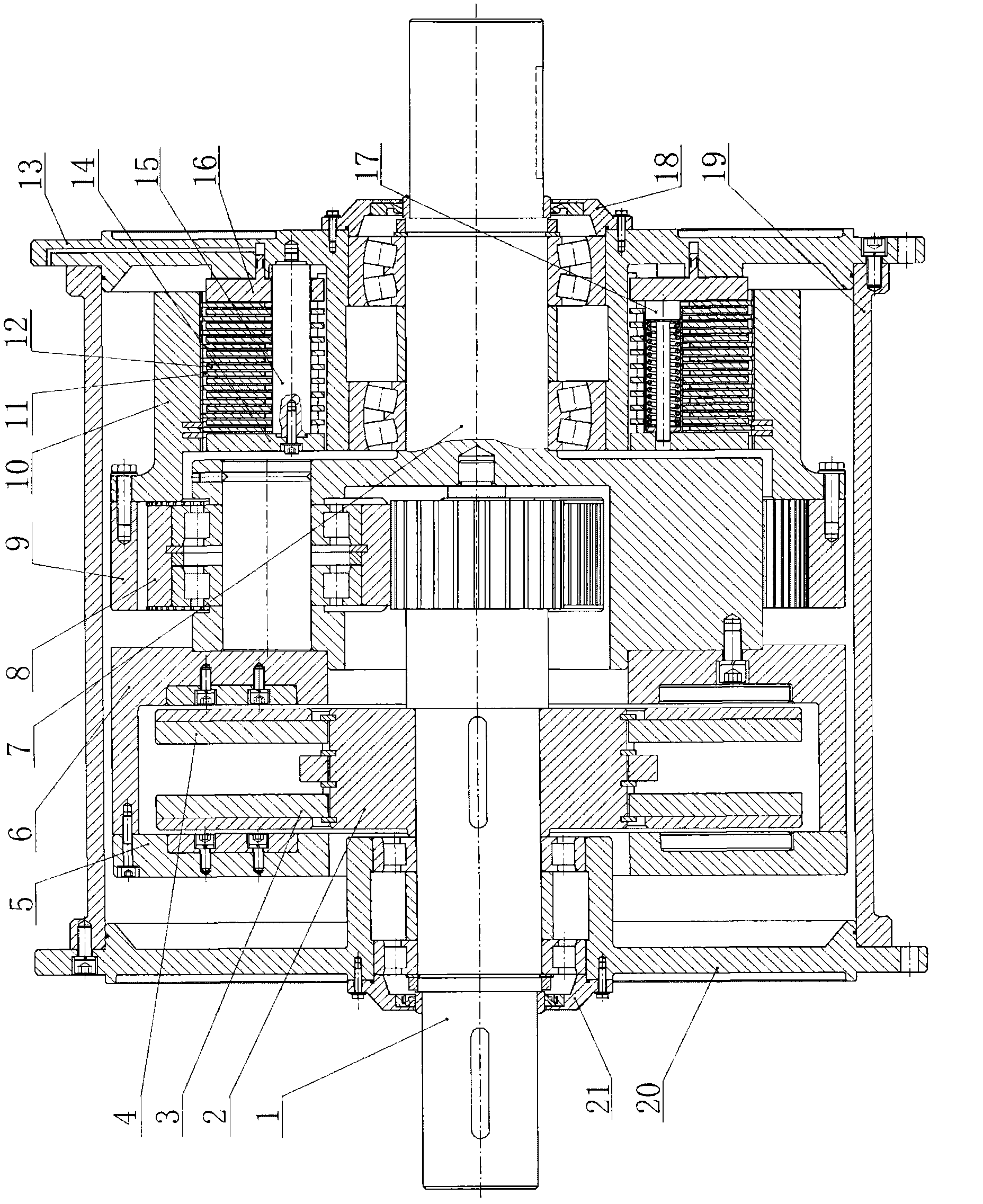

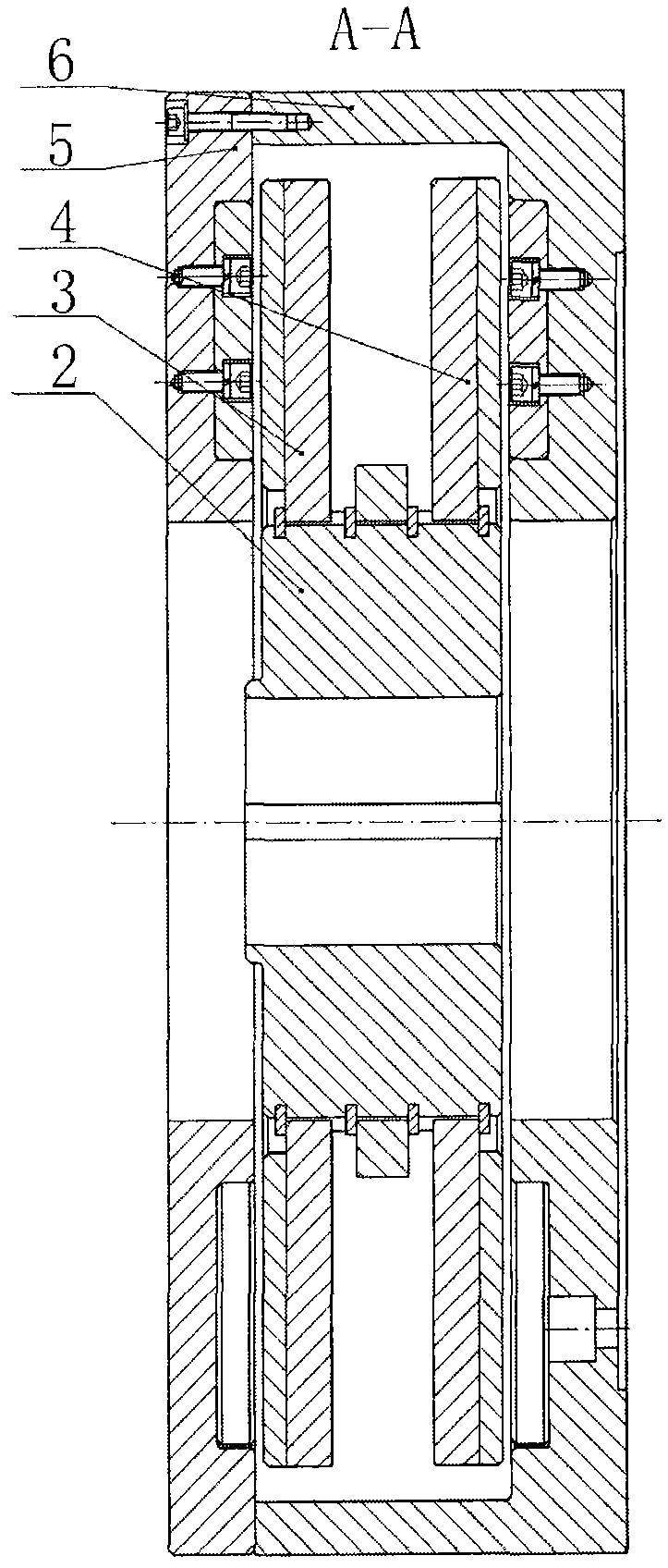

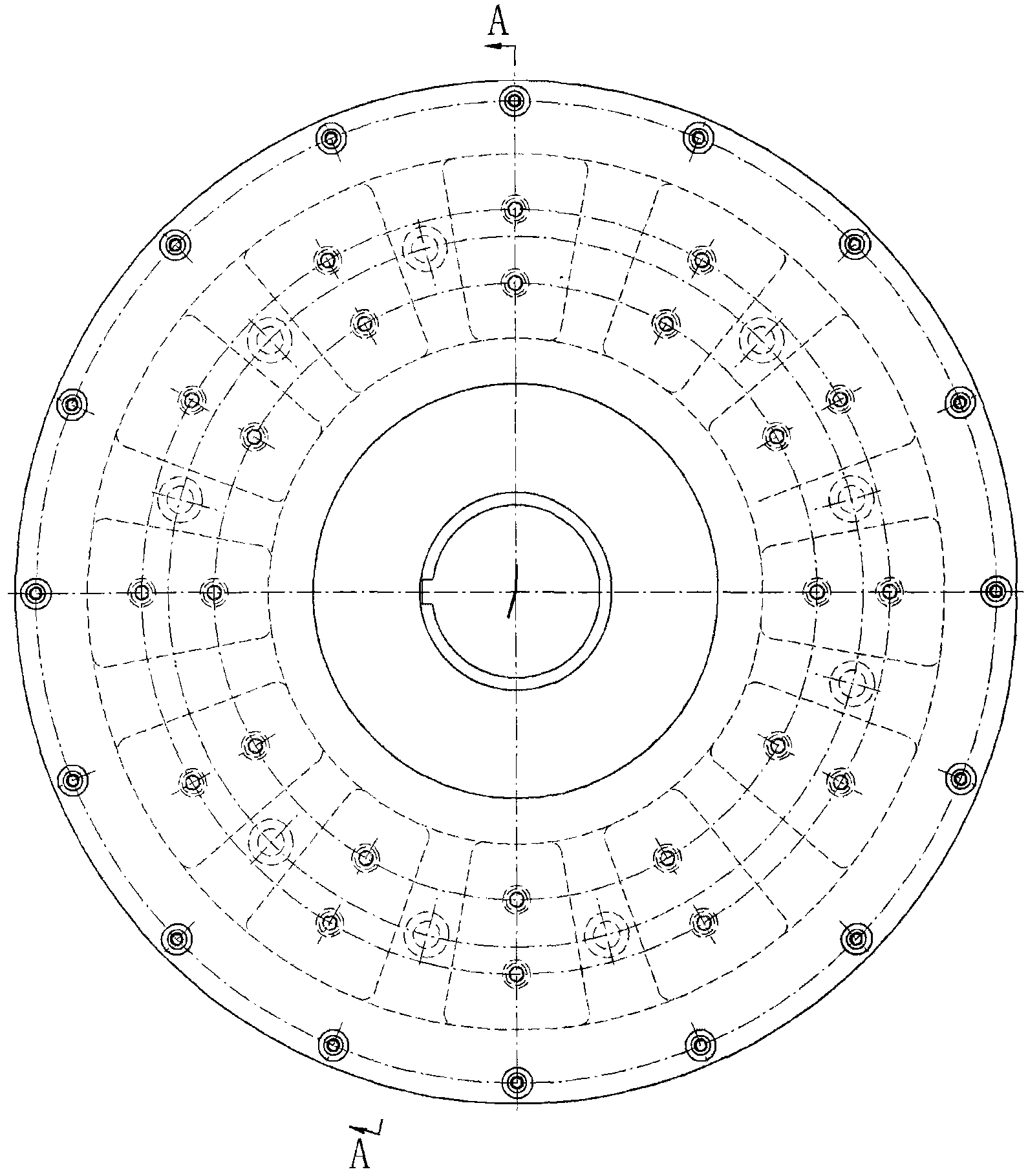

[0026] In the figure 1. sun gear, 2. magnet guide sliding bush assembly, 3. front guide magnet assembly, 4. rear guide magnet assembly, 5. front permanent magnet assembly, 6. rear permanent magnet assembly, 7. planet carrier, 8 .Planetary gear, 9. Inner ring gear, 10. Inner spline sleeve, 11. Dynamic clutch plate, 12. Static clutch plate, 13. External spline key seat, 14. Fixed plate, 15. Fixed pin shaft, 16. Sliding Pressure plate, 17. anti-compression spring assembly, 18. output bearing cover, 19. casing, 20. input disc seat, 21. input bearing cover.

[0027] The device is composed of three parts: permanent magnet coupling transmission system, planetary transmission system, and hydraulic control friction clutch system;

[0028] Permanent magnet coupling transmission system: composed of magnet guide sliding sleeve assembly 2, leading magnet assembly 3, rear magnet guide assembly 4, front permanent magnet assembly 5, and rear permanent magnet assembly 6;

[0029] The internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com