Lead powder machine

A technology of lead powder machine and powder collector, which is applied in the field of lead powder machine, can solve problems such as low production efficiency, reduced production capacity, and reduced friction and grinding of lead balls, so as to eliminate lead powder clogging, avoid powder burning, and improve production efficiency. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

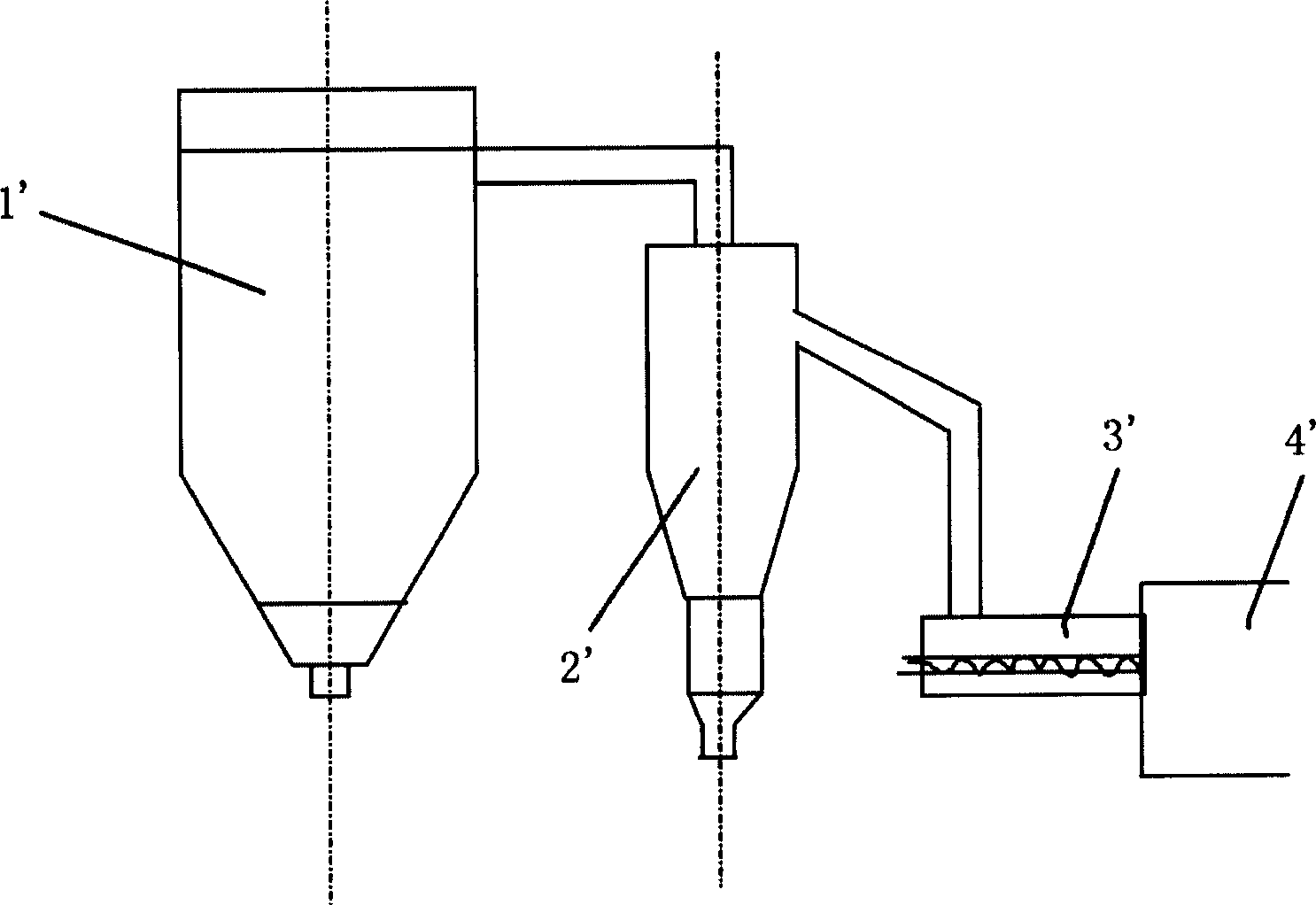

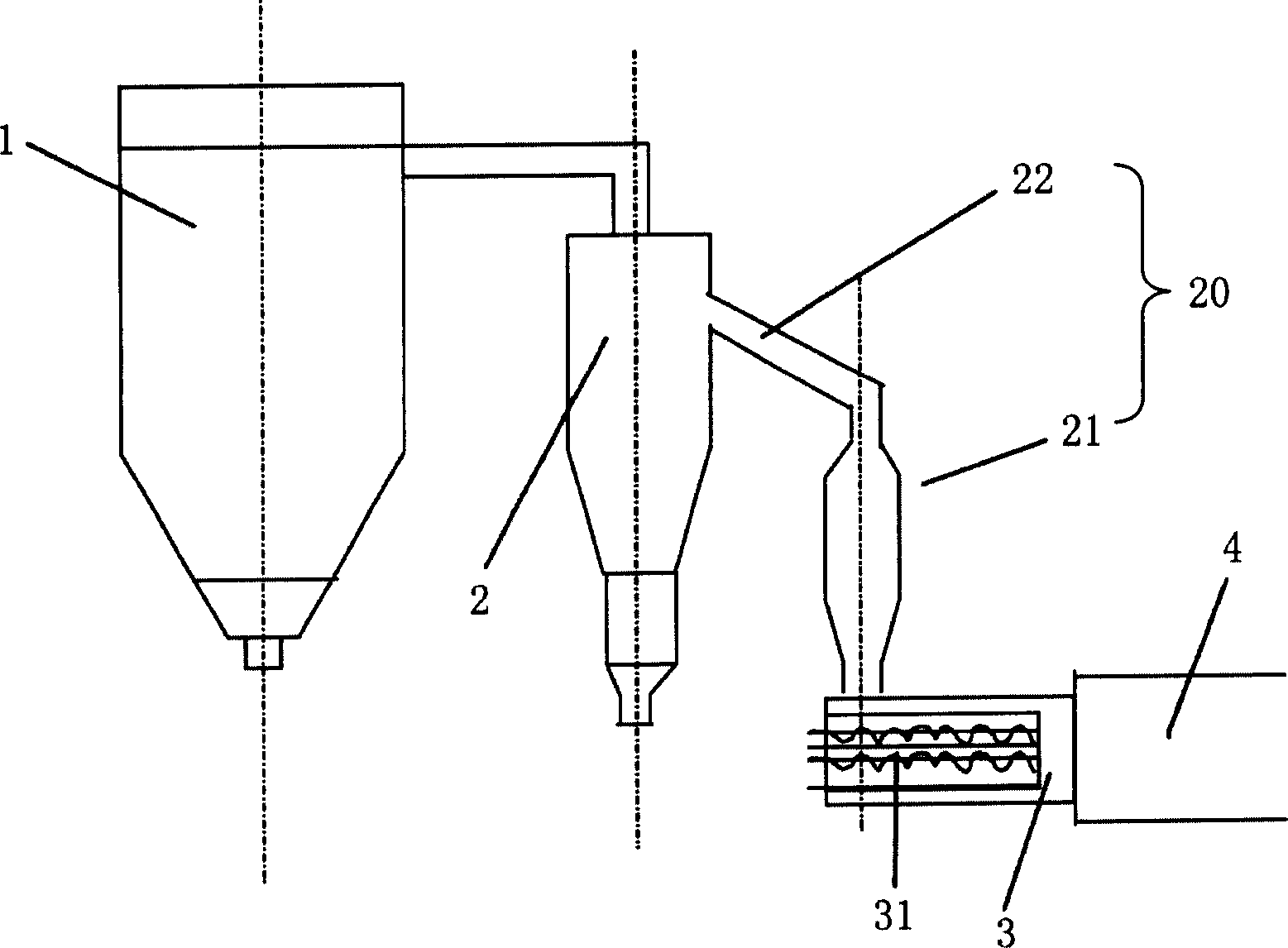

[0021] Please refer to figure 2 As shown, the lead powder machine 100 of the present invention includes a powder collector 1, a cyclone separator 2 connected to the powder collector 1 through a pipeline (not labeled), a drum 4 and a hollow shaft 3 connected to the drum 4, the hollow shaft 3 There are at least two powder returning screws 31 inside, and the hollow shaft 3 is connected with the cyclone separator 2 through a pipeline 20 . The powder collector 1, the cyclone separator 2 and the drum 4 of the lead powder machine 100 of the present invention are the same as those of the prior art, and will not be described here. Only the differences between the present invention and the prior art will be described in detail below.

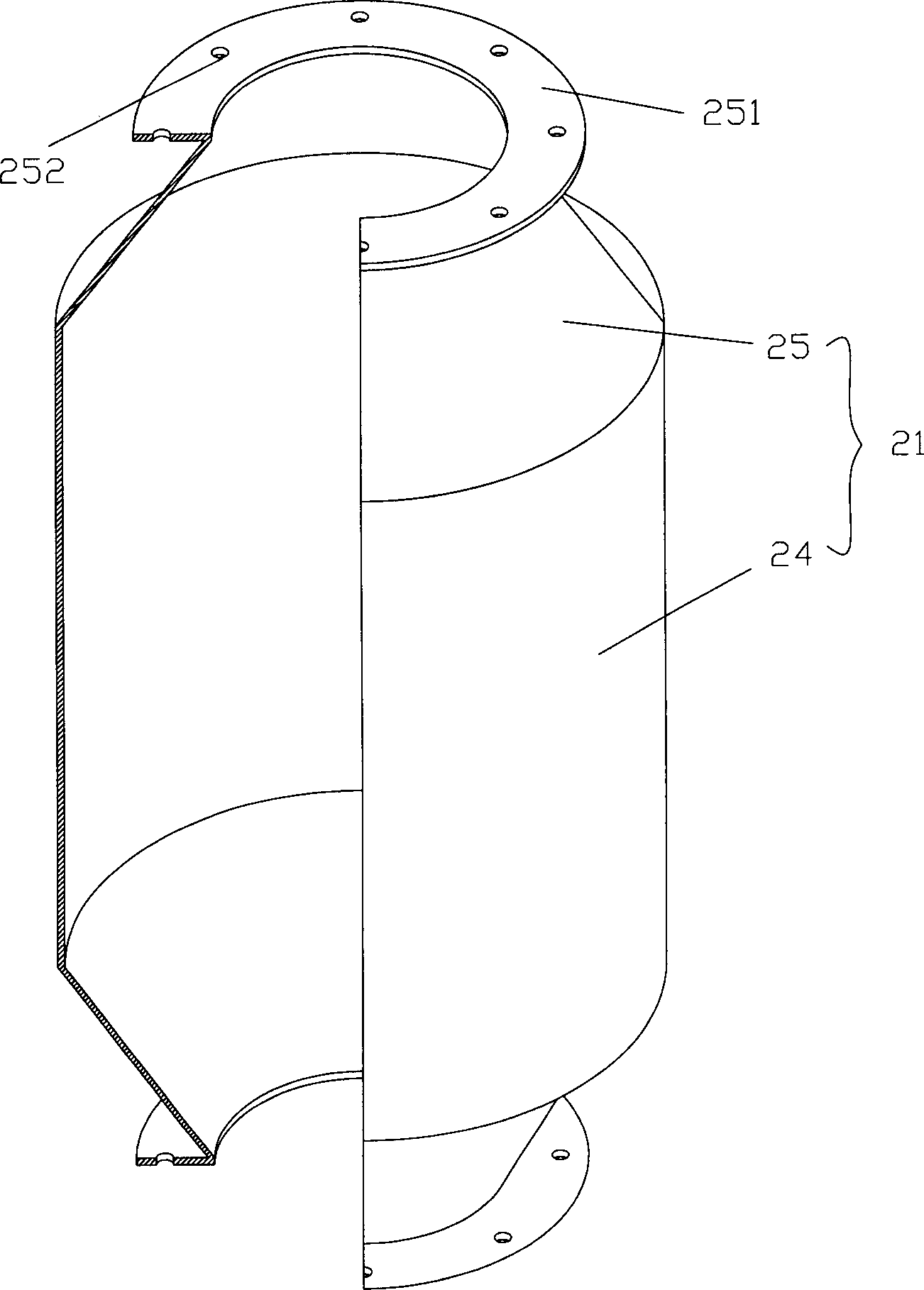

[0022] Please refer to figure 2 , image 3 As shown, the pipe 20 includes an upright pipe 21 and an inclined pipe 22 , and the upright pipe 21 includes a thickened portion 24 and necks 25 respectively connected to the upper and lower ends of the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com