A kind of preparation method of coplanar waveguide structure micro-LED

A coplanar waveguide and area technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of high-frequency signal feeding of array LEDs, heat dissipation of high-power LEDs, etc., to break through power shortage, optimize heat dissipation performance, and improve heat dissipation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

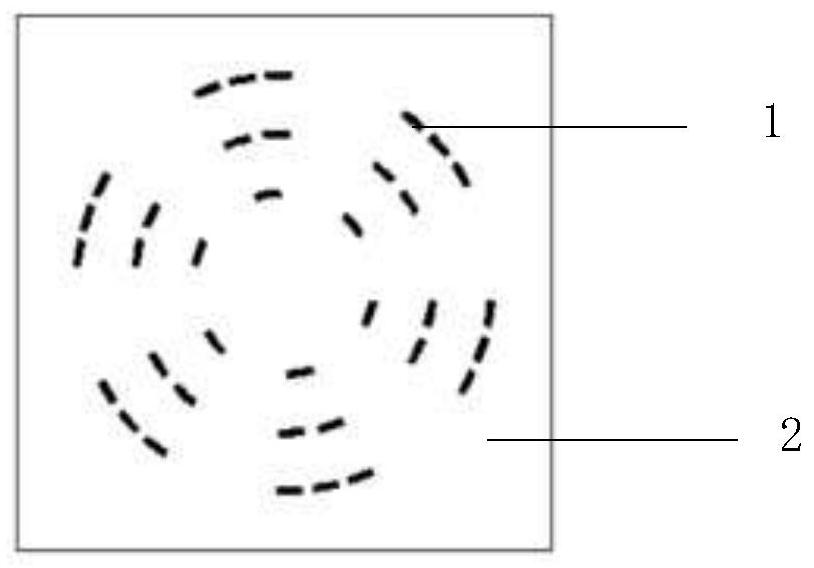

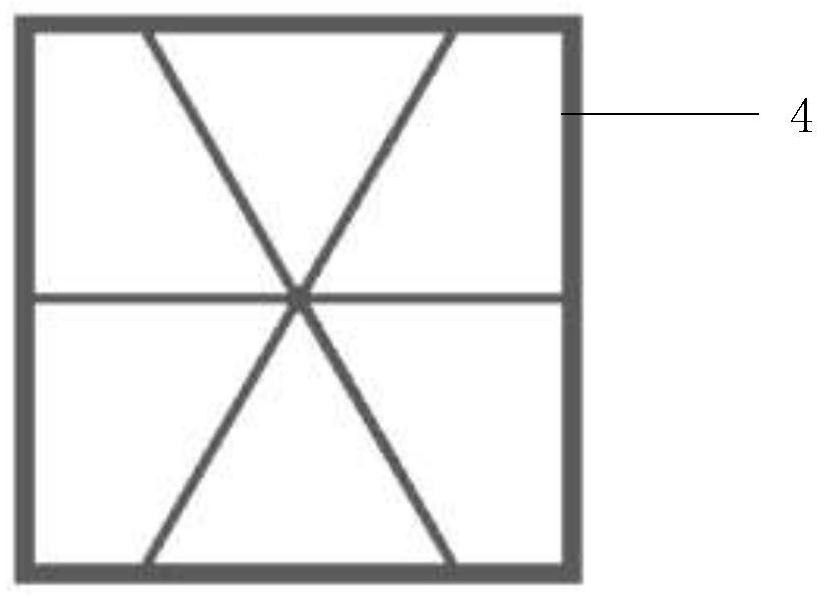

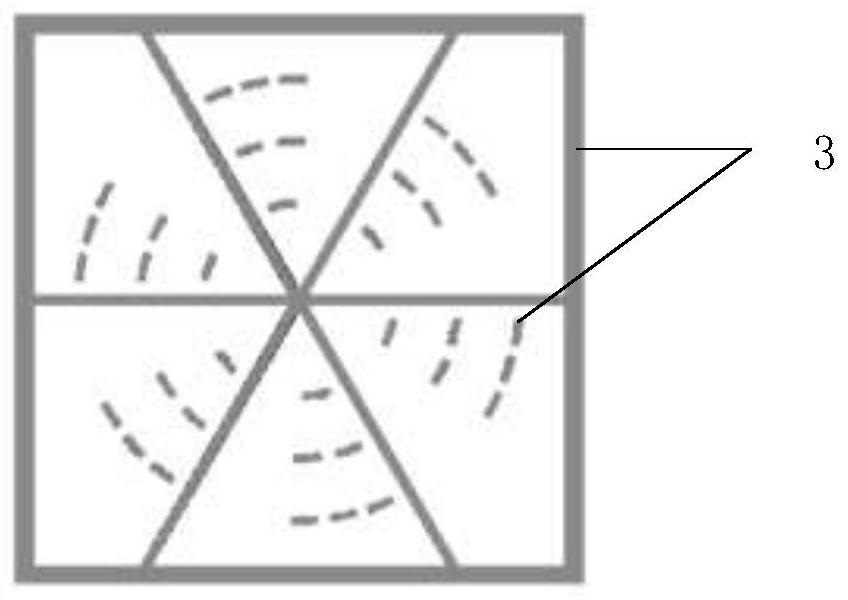

[0031] First, determine the area of a single micron LED in the array and the total number of LEDs according to the final power requirement, where the area of a single LED is 888um 2 , the total number of LEDs is 36. By simulating heat distribution, current distribution, and high-frequency signal feed-in conditions, and then according to the simulation effect, optimize and design six LED mesa areas divided by isolation areas, as well as the electrode structure.

[0032] After the sapphire substrate LED epitaxial wafer is pickled, organically cleaned, rinsed with deionized water until the surface is free of contamination and oxide layer and dried, a layer of ITO is evaporated as a current spreading layer;

[0033] The photoresist is coated by the coater, and through exposure and development, a number of radially distributed fan-shaped mesa a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com