Multi-nozzle multi-channel color 3D printer

A 3D printer and multi-channel technology, applied to 3D object support structures, coating devices, manufacturing tools, etc., can solve the problems of increasing production costs, time-consuming and labor-intensive, etc., to facilitate disassembly and maintenance, and avoid misfeeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

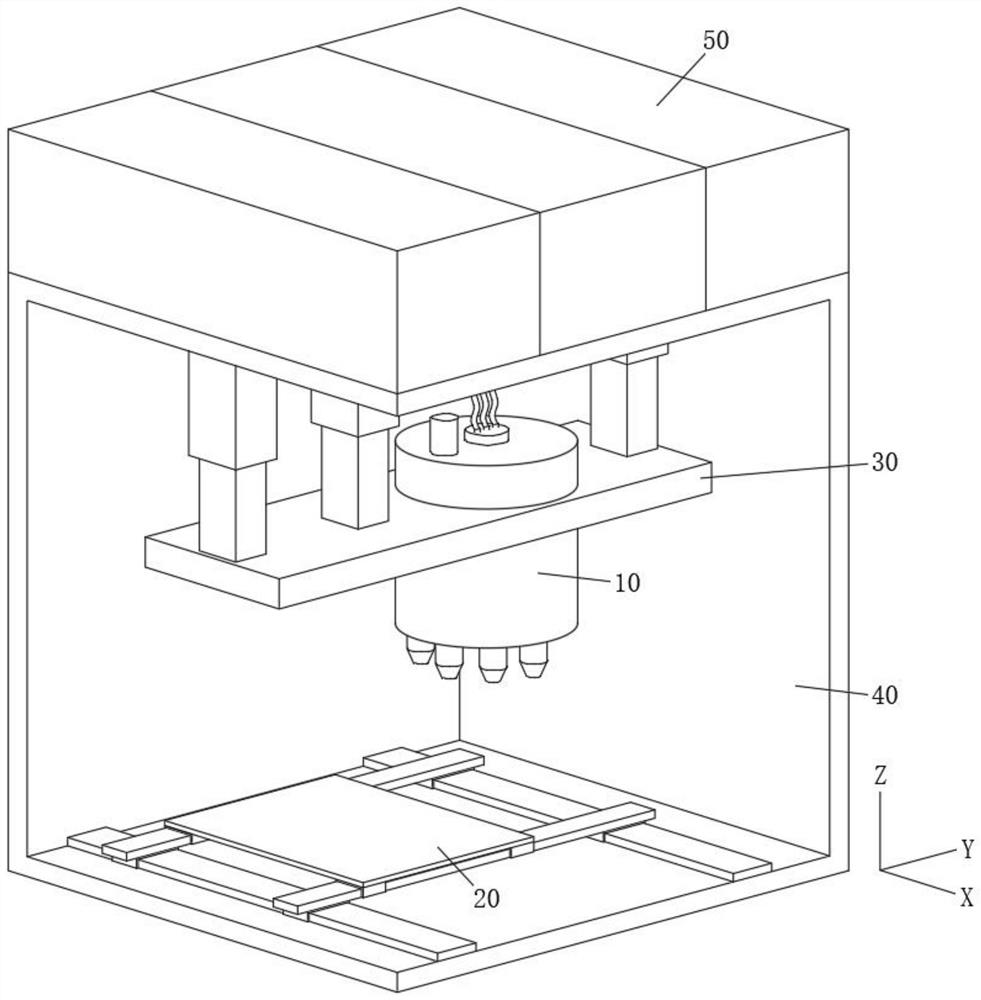

[0035] see Figure 1-Figure 8 As shown, a multi-nozzle multi-channel color 3D printer is provided in this embodiment, and the 3D printer mainly includes:

[0036] installation box 40;

[0037] The printing platform 20 that is arranged inside the installation box 40 and can move freely in the horizontal plane;

[0038] A lifting platform 30 arranged inside the installation box 40 and capable of reciprocating lifting in a vertical plane;

[0039] The printing nozzle 10 fixedly installed on the lifting platform 30;

[0040] There are N supply boxes 50 fixed on the top of the installation box 40 , and the supply boxes 50 are used to supply dyed printing materials to the print heads 10 .

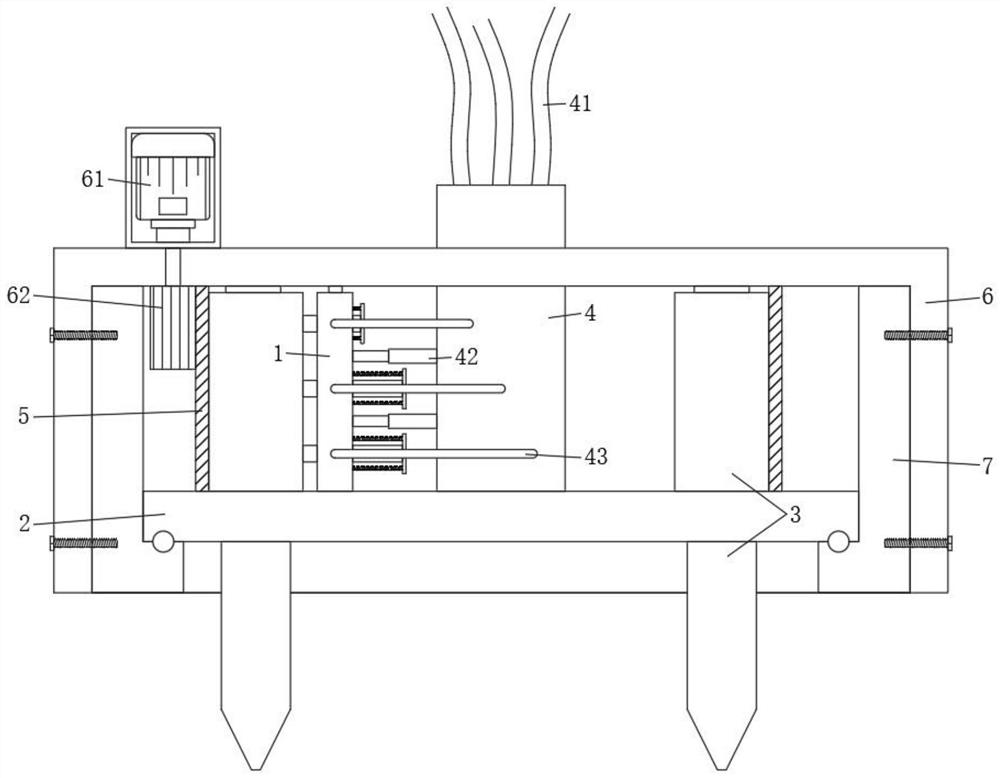

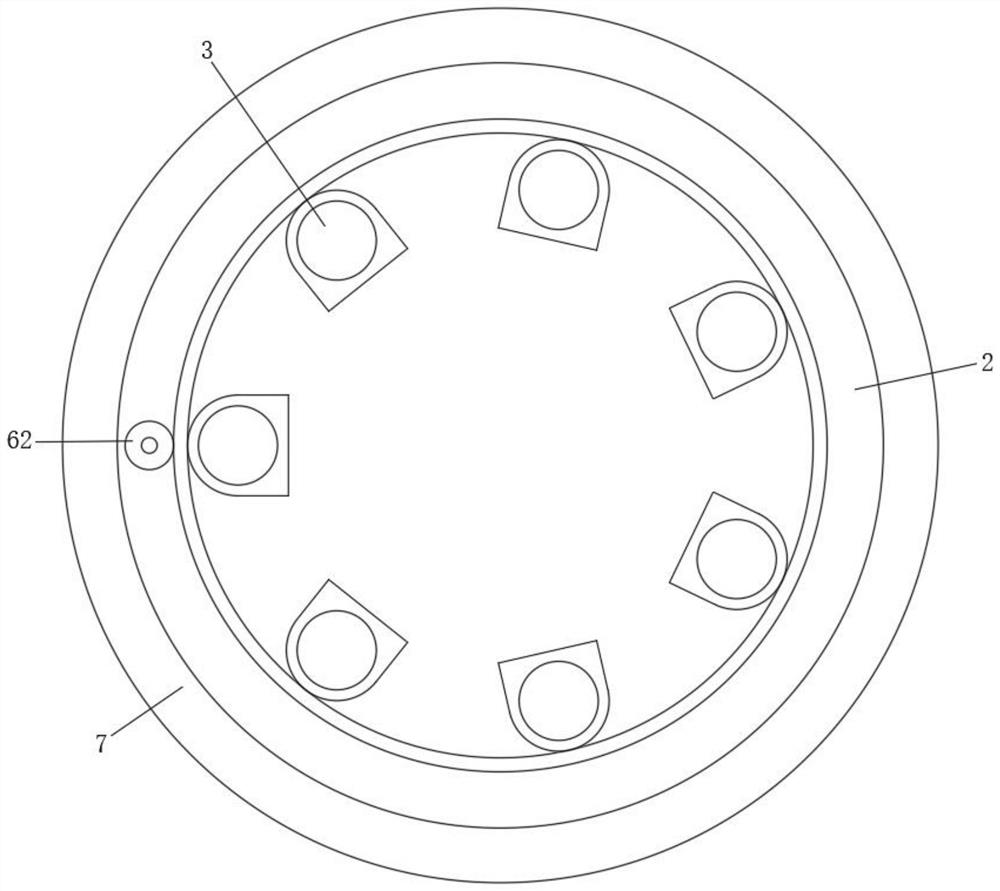

[0041] The above-mentioned print head 10 includes a housing and the following structures arranged in the housing:

[0042] The feeding box 1 has N feeding cavities 11 inside the feeding box 1, and a movable feeding tube 12 runs through each feeding cavity 11. The feeding tube 12 is a hollow t...

Embodiment 2

[0056] see figure 1 , Figure 9-Figure 10 As shown, a multi-nozzle multi-channel color 3D printer is provided in this embodiment, and the 3D printer mainly includes:

[0057] Installation box 40

[0058] The printing platform 20 that is arranged inside the installation box 40 and can move freely in the horizontal plane;

[0059] A lifting platform 30 arranged inside the installation box 40 and capable of reciprocating lifting in a vertical plane;

[0060] The printing nozzle 10 fixedly installed on the lifting platform 30;

[0061] There are N supply boxes 50 fixed on the top of the installation box 40 , and the supply boxes 50 are used to supply dyed printing materials to the print heads 10 .

[0062] Above-mentioned print head 10 comprises:

[0063] The above-mentioned print head 10 includes a housing and the following structures arranged in the housing:

[0064] The feeding box 1 has N feeding cavities 11 inside the feeding box 1, and a movable feeding tube 12 runs th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com