A kitchen waste recycling device

A technology for recycling and processing kitchen waste, applied in the direction of solid waste removal, etc., can solve the problems of large floor space, large losses, poor treatment effect of kitchen waste, etc., and achieve the effect of avoiding garbage leakage, convenient operation and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

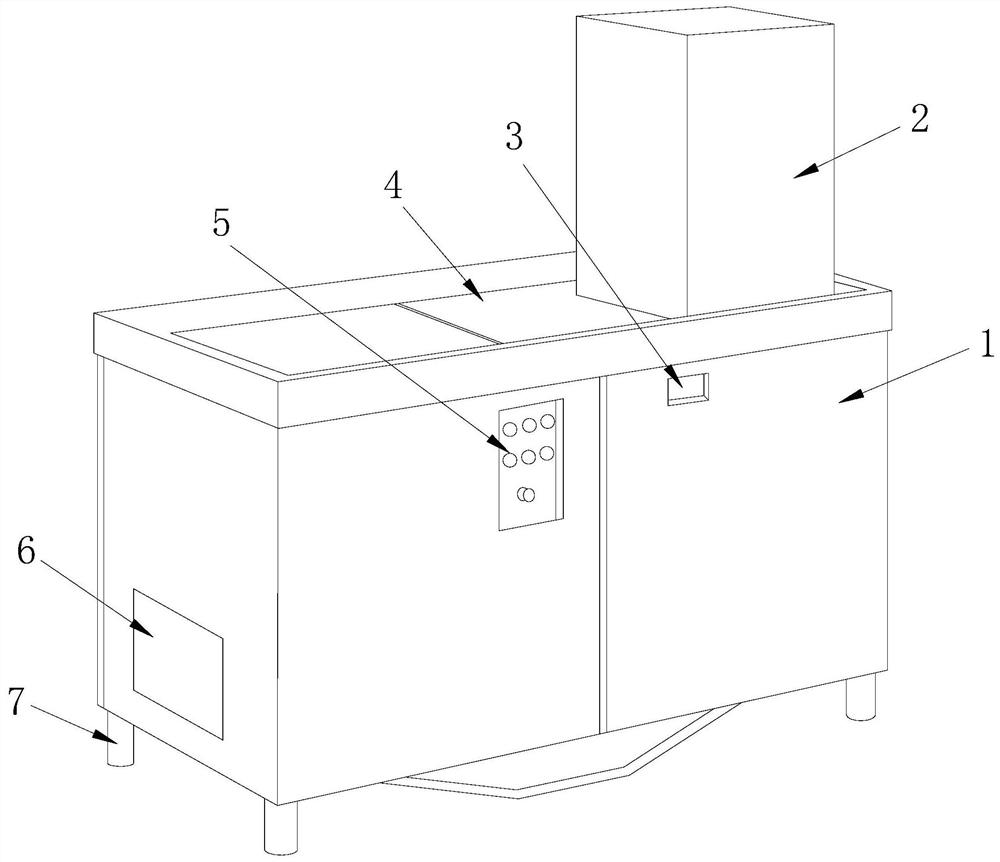

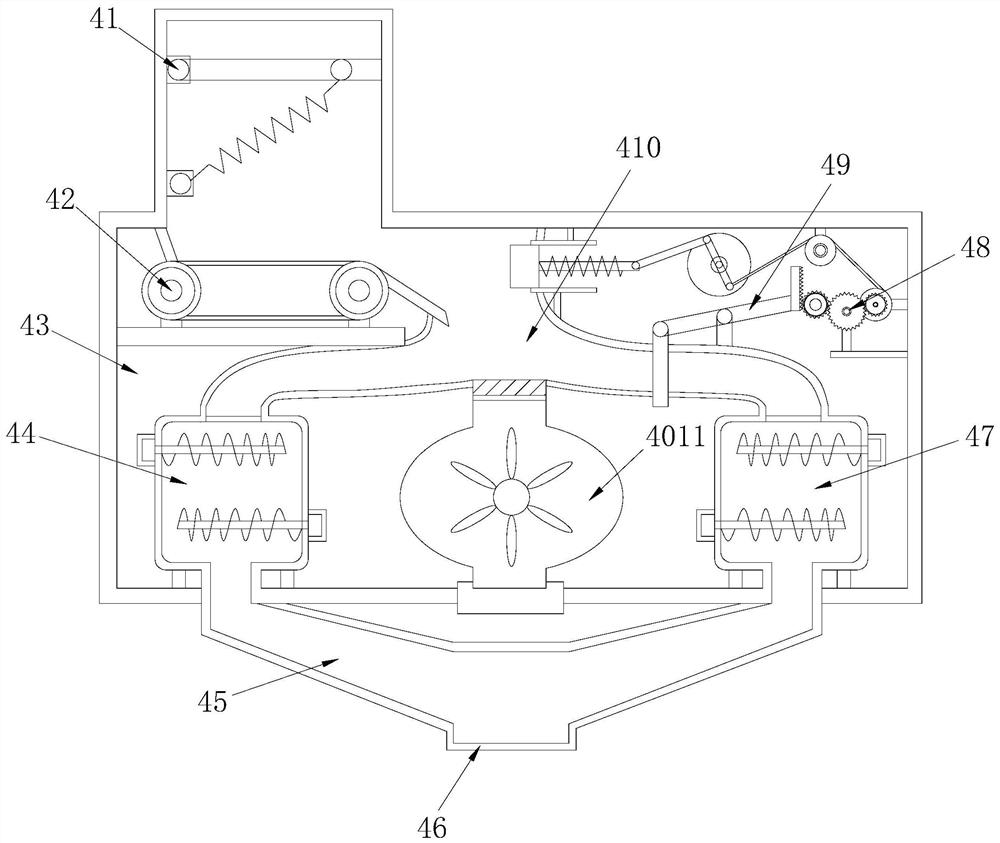

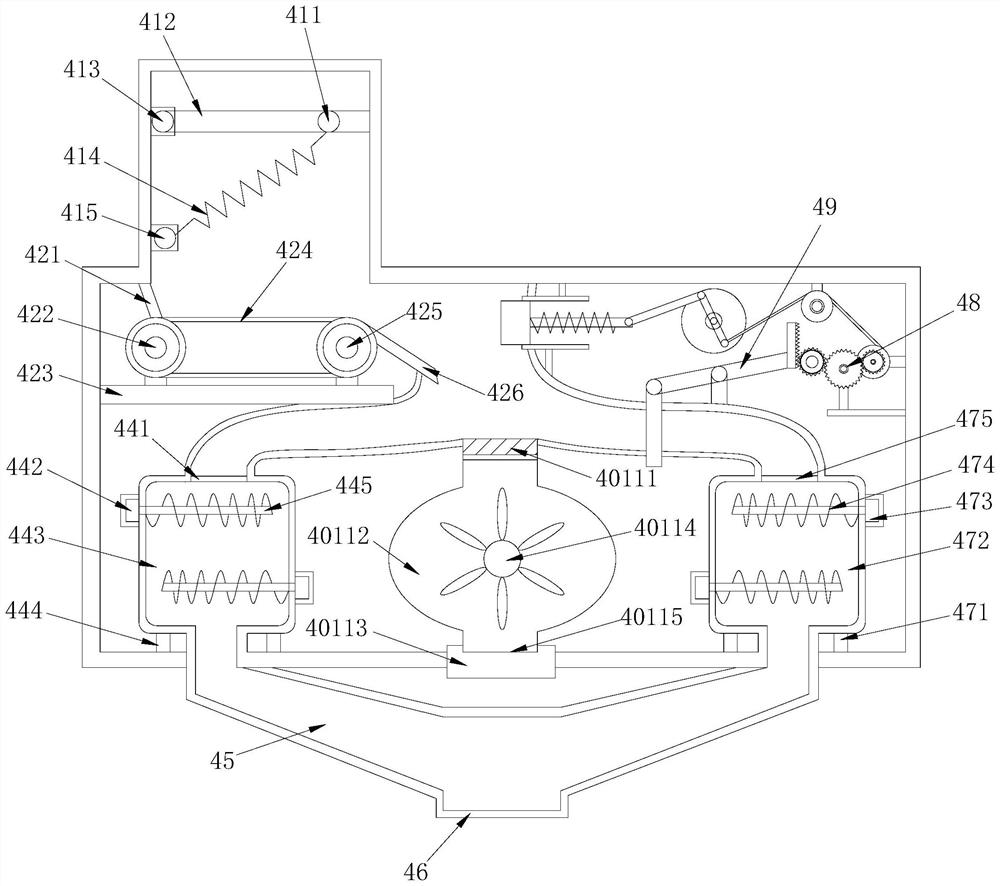

[0024] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of kitchen rubbish recovery treatment device, and its structure comprises cabinet door 1, material inlet 2, inspection port 3, workbench 4, operation panel 5, cooling outlet 6, support foot 7, and described workbench 4 is a cuboid structure and two cabinet doors 1 are hingedly connected to the front end. The cabinet door 1 is provided with an inspection port 3 to cooperate with the workbench 4. The operation panel 5 is installed on the cabinet door 1 and located at the inspection port 3 The left end of the workbench 4 is electrically connected to the electrical system inside the workbench 4. The bottom end of the inlet 2 is welded to the right side of the upper end surface of the workbench 4. The left end surface of the workbench 4 is connected with a heat dissipation port 6 by bolts. The supporting feet 7 are provided with four and evenly welded on the four corners of the bottom end of the workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com