Producing object connecting device and carrying system therewith

A technology for a handover device and a manufacturing device, applied in the field of conveying systems, can solve the problems of inability to process wafers smoothly, reduced wafer production efficiency, surplus production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

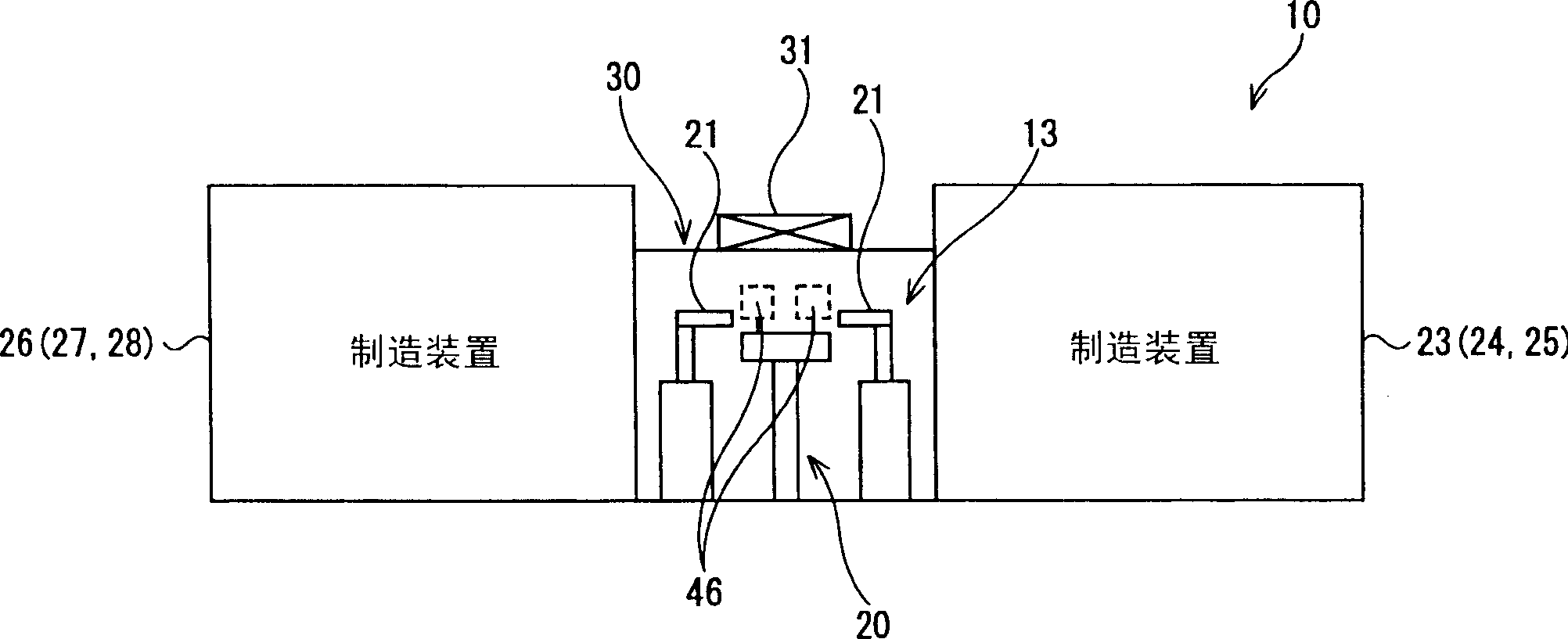

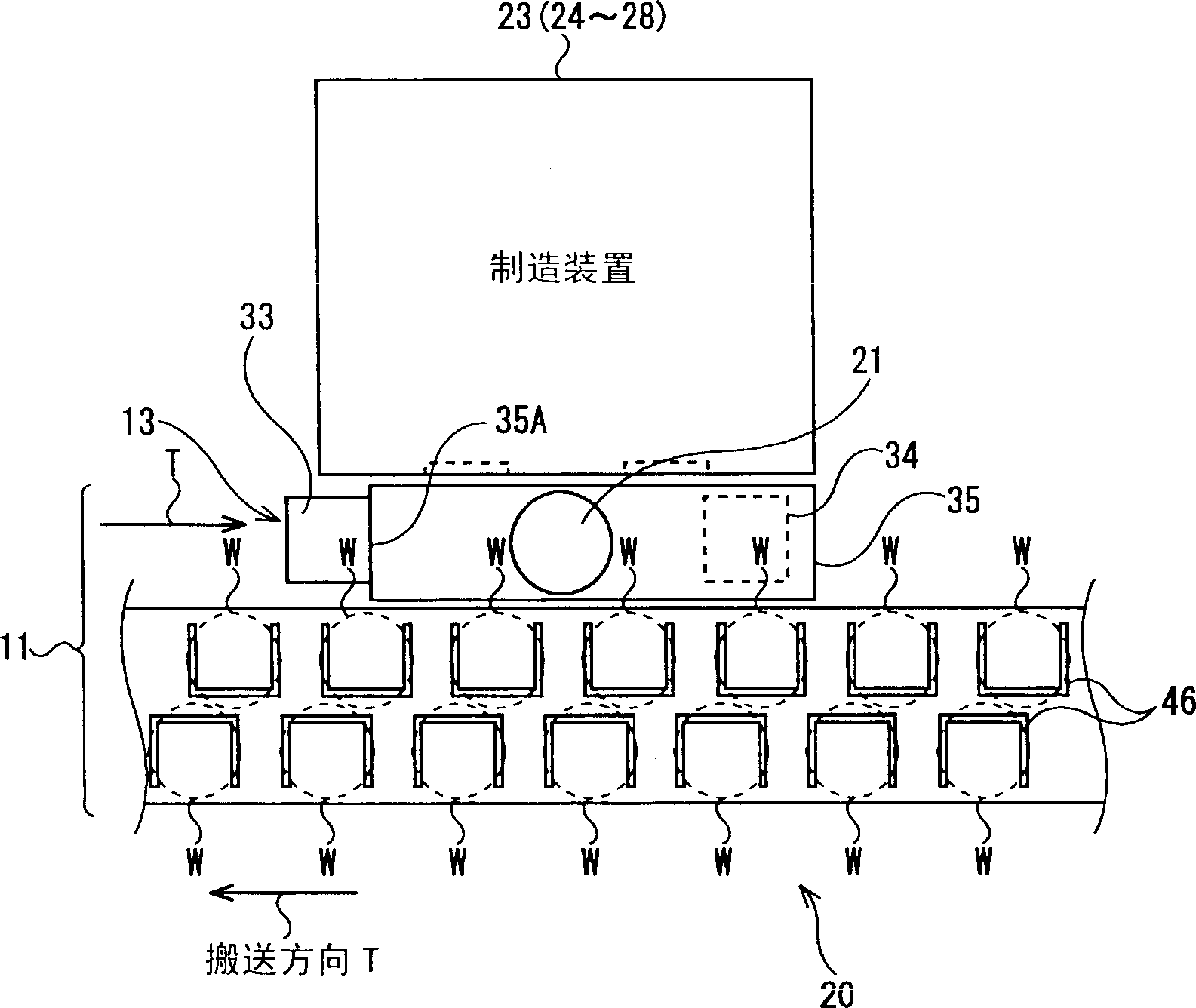

[0069] Figure 3 ~ Figure 8 Embodiment 1 of the manufacture object delivery apparatus 13 of this invention is shown.

[0070] image 3 It is a plan view representatively showing the manufacturing target delivery device 13 and one manufacturing device 23 . Figure 4 and Figure 5 It is a perspective view representatively showing the manufacturing target delivery device 13 and one manufacturing device 23 .

[0071] exist Figure 3 ~ Figure 5 Among them, the manufacturing target delivery device 13 has a transfer robot 21 , a buffer 34 , a loading port (a type of auxiliary port) 33 , and a main body 35 .

[0072] The main body 35 is disposed between the manufacturing device 23 and the single-sheet conveying conveyor 20 . The main body 35 accommodates the transfer robot 21 and the buffer 34 described above inside.

[0073] The loading port 33 protrudes laterally from one side portion 35A of the main body 35 . The protruding direction of the loading port 33 is parallel to the...

Embodiment 2

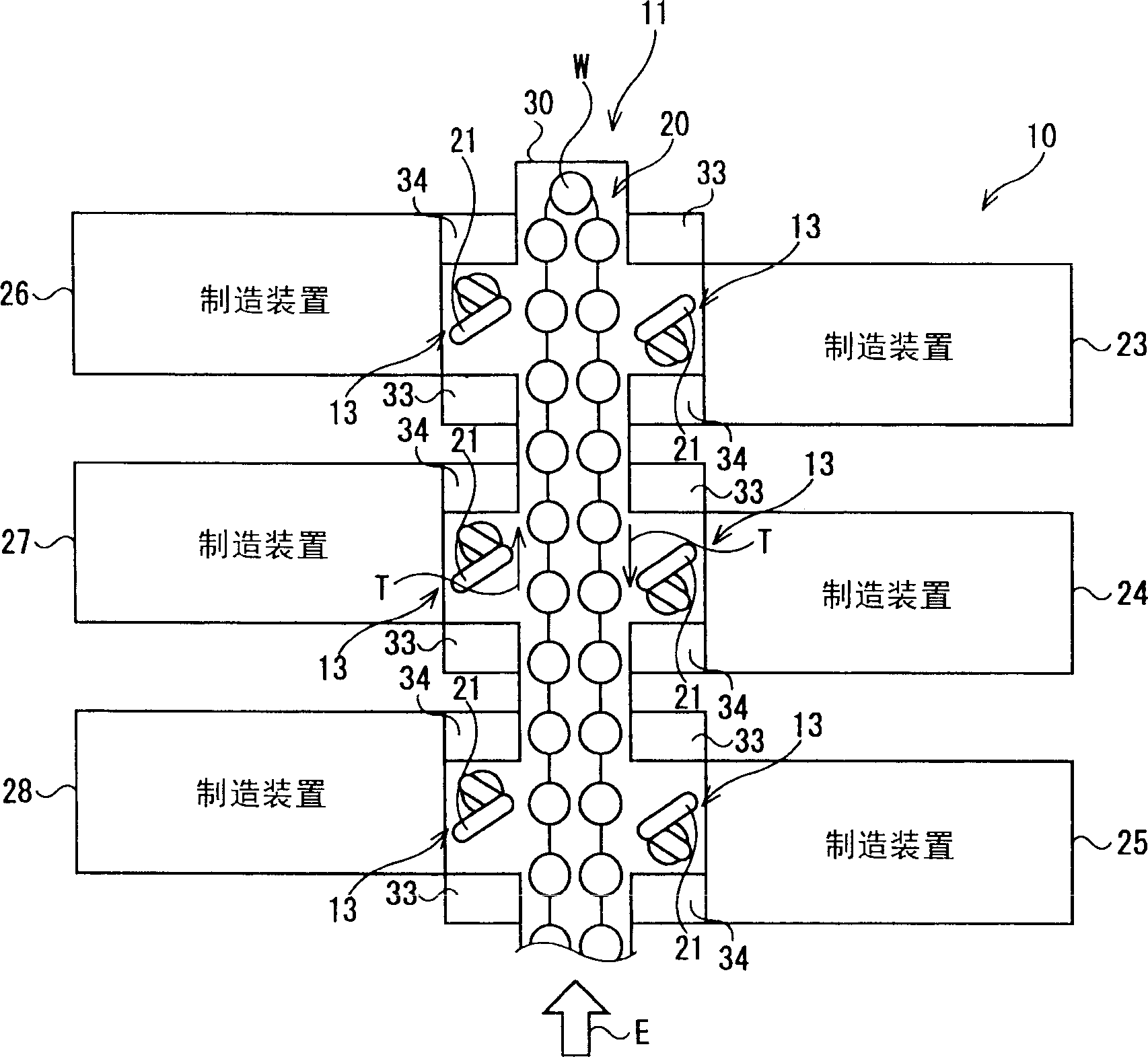

[0106] Below, explain Figure 10 ~ Figure 12 Embodiment 2 of the conveyor system of the present invention is shown.

[0107] Figure 10 ~ Figure 12 shown in Example 2 and Figure 3 ~ Figure 5 Compared with the first embodiment shown, the manufacturing apparatus 23 ( 24 to 28 ) and the single-sheet conveying conveyor 20 have the same structure.

[0108] The transfer system 11 has a single sheet transfer conveyor 20 and an object delivery device 13 . Figure 10 ~ Figure 12 The structure of the manufactured object transfer device 13 and Figure 3 ~ Figure 5 The illustrated object delivery device 13 has a different structure.

[0109] Therefore, the manufactured object delivery device 13 will be described. To manufacturing device 23 (24~28) and single piece conveying conveyor belt 20, adopt Figure 3 ~ Figure 5 Description of the manufacturing apparatus 23 (24-28) and the single sheet conveying conveyor 20.

[0110] Figure 10 ~ Figure 12 The manufacturing apparatus 23 sho...

Embodiment 3

[0122] Figure 13 ~ Figure 15 Example 3 of the transport system of the present invention is shown.

[0123] Figure 13 ~ Figure 15 Shown in Example 3 with Figure 10 ~ Figure 12 The same parts as in the illustrated second embodiment are the configurations of the manufacturing device 23 ( 24 to 28 ), the wafer transfer device 61 , and the single-chip transfer conveyor 20 . Figure 13 ~ Figure 15 The structure and Figure 10 ~ Figure 12 The configuration of the manufacturing target delivery device 13 of the illustrated second embodiment is slightly different.

[0124] Therefore, stating Figure 13 ~ Figure 15 The configuration of the manufacturing target delivery device 13 is shown.

[0125] Such as Figure 13 ~ Figure 15 As shown, the manufactured object delivery device 13 has a main body 235 . The main body 235 is rectangular in plan view. On the upper surface of the main body 235, a filter device 38 with a fan is provided. The filter unit 38 with a fan creates an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com