Precision forming method for straight/helical tooth cylinder gear with corners easy to fill and die

A technology of precision forming and corners, applied in the direction of wheels, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of high manufacturing cost, inconvenient practical application, and large stress ball tensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] specific implementation

[0105] The present invention will be further described through the following embodiments in conjunction with the accompanying drawings.

[0106] Example.

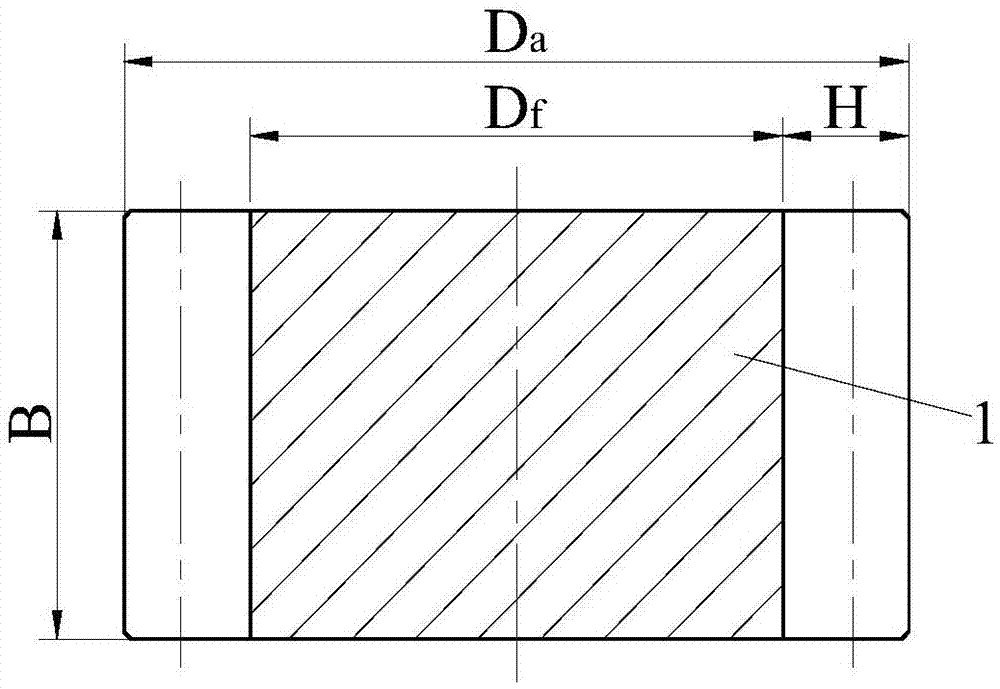

[0107] Take a cylindrical gear (tooth number z=12, modulus m=4, tooth width B=30mm, tooth height H=9mm. See attached figure 1 ) The precision forming process is an embodiment.

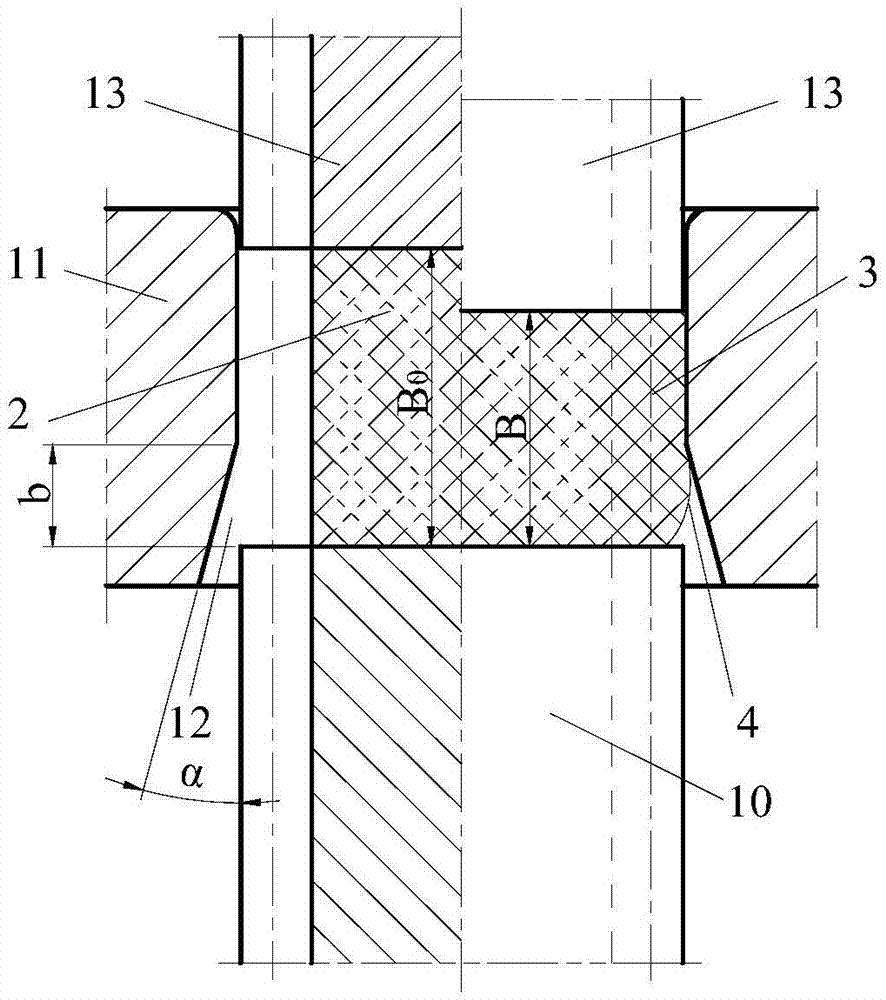

[0108] First introduce its precision forming mold. Mold is made up of lower punch 10, die 11, upper punch 13 (see attached image 3 , attached Figure 4 ).

[0109] The main body of the cavity of the die 11 is in a through shape, but the side walls are not completely straight-through, and the middle and lower sections of the tooth top cavity are cavity expansion spaces 12 (corresponding to the lower corner of the gear and the adjacent area, see the attached Figure 12 , attached Figure 13 , attached Figure 14 , attached Figure 15 , attached Figure 17 , attached Figure 18 ), the meridional plane size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com