Processing method for deodorized soybean milk

A processing method and soymilk technology, applied in milk substitutes, dairy products, food science, etc., can solve problems such as ineffective removal and heavy beany smell of soymilk, improve product flavor and taste, aggravate soybean protein denaturation, and process steps simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

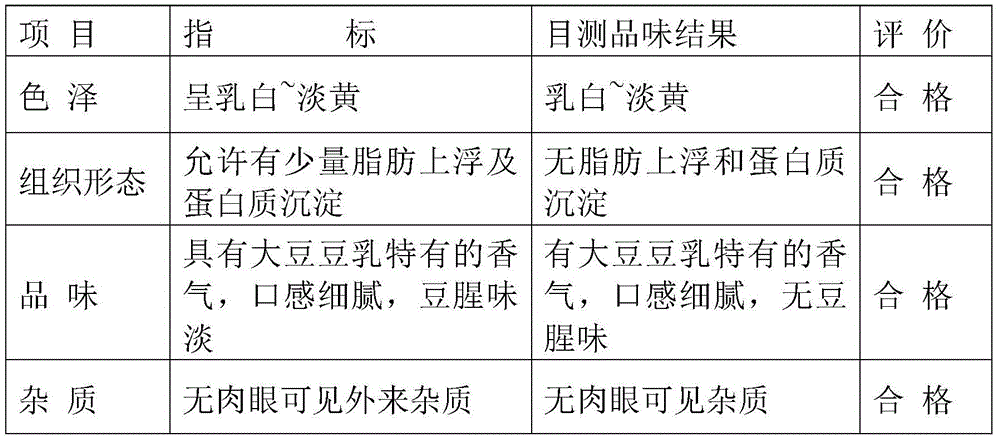

Examples

Embodiment 1

[0026] (1) Soaking: Select clean, mature and fresh soybeans, and add them into the sodium erythorbate solution with a temperature of 20°C and a mass percentage concentration of 0.03% according to the mass ratio of soybeans to sodium erythorbate solution of 1:5. Soak for 6-8 hours, peel and remove the germ to obtain peeled soybeans for later use.

[0027] (2) Refining: dissolving sodium bicarbonate in water to form a sodium bicarbonate solution with a concentration of 0.2%, mixing the dehulled soybeans with the sodium bicarbonate solution at a mass ratio of 1:8, and refining under anaerobic conditions , the specific steps of refining are: first grind to a coarsely ground paste with a fineness of 400 μm, and then grind the coarsely ground paste to a finely ground paste with a fineness of 180 μm.

[0028] (3) Centrifuge to remove slag: add a deodorizing agent of 3% of the mass of the finely ground paste to the finely ground paste, in a stirring state, incubate at a temperature of...

Embodiment 2

[0034] (1) Soaking: Select clean, mature and fresh soybeans, and add them into the sodium erythorbate solution with a temperature of 25°C and a mass percent concentration of 0.04% according to the mass ratio of soybeans to sodium erythorbate solution at a ratio of 1:7. Soak for 7 hours, peel and remove the germ to obtain peeled soybeans for later use.

[0035] (2) Refining: dissolving sodium bicarbonate in water to form a sodium bicarbonate solution with a concentration of 0.25%, mixing the dehulled soybeans with the sodium bicarbonate solution at a mass ratio of 1:9, and refining under anaerobic conditions , the specific steps of refining are: first grind to a coarsely ground paste with a fineness of 600 μm, and then grind the coarsely ground paste to a finely ground paste with a fineness of 190 μm.

[0036](3) Centrifuge to remove slag: Add a deodorizing agent with 4% of the quality of the finely ground paste into the finely ground paste, in a stirring state, incubate at a t...

Embodiment 3

[0042] (1) Soaking: Select clean, mature and fresh soybeans, and add them into the sodium erythorbate solution with a temperature of 30°C and a mass percentage concentration of 0.05% according to the mass ratio of soybeans and sodium erythorbate solution at a ratio of 1:10. Soak for 8 hours, peel and remove the germ to obtain peeled soybeans for later use.

[0043] (2) Refining: dissolving sodium bicarbonate in water to form a sodium bicarbonate solution with a concentration of 0.3%, mixing the dehulled soybeans with the sodium bicarbonate solution at a mass ratio of 1:10, and refining under anaerobic conditions , the specific steps of refining are: first grind to a coarsely ground paste with a fineness of 800 μm, and then grind the coarsely ground paste to a finely ground paste with a fineness of 200 μm.

[0044] (3) Centrifuge to remove slag: add a deodorizing agent with 5% of the quality of the finely ground paste into the finely ground paste, keep it warm at 50°C for 4 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com