R-T-B based permanent magnet

A permanent magnet, R-T-B technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve problems such as influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described below.

[0042]

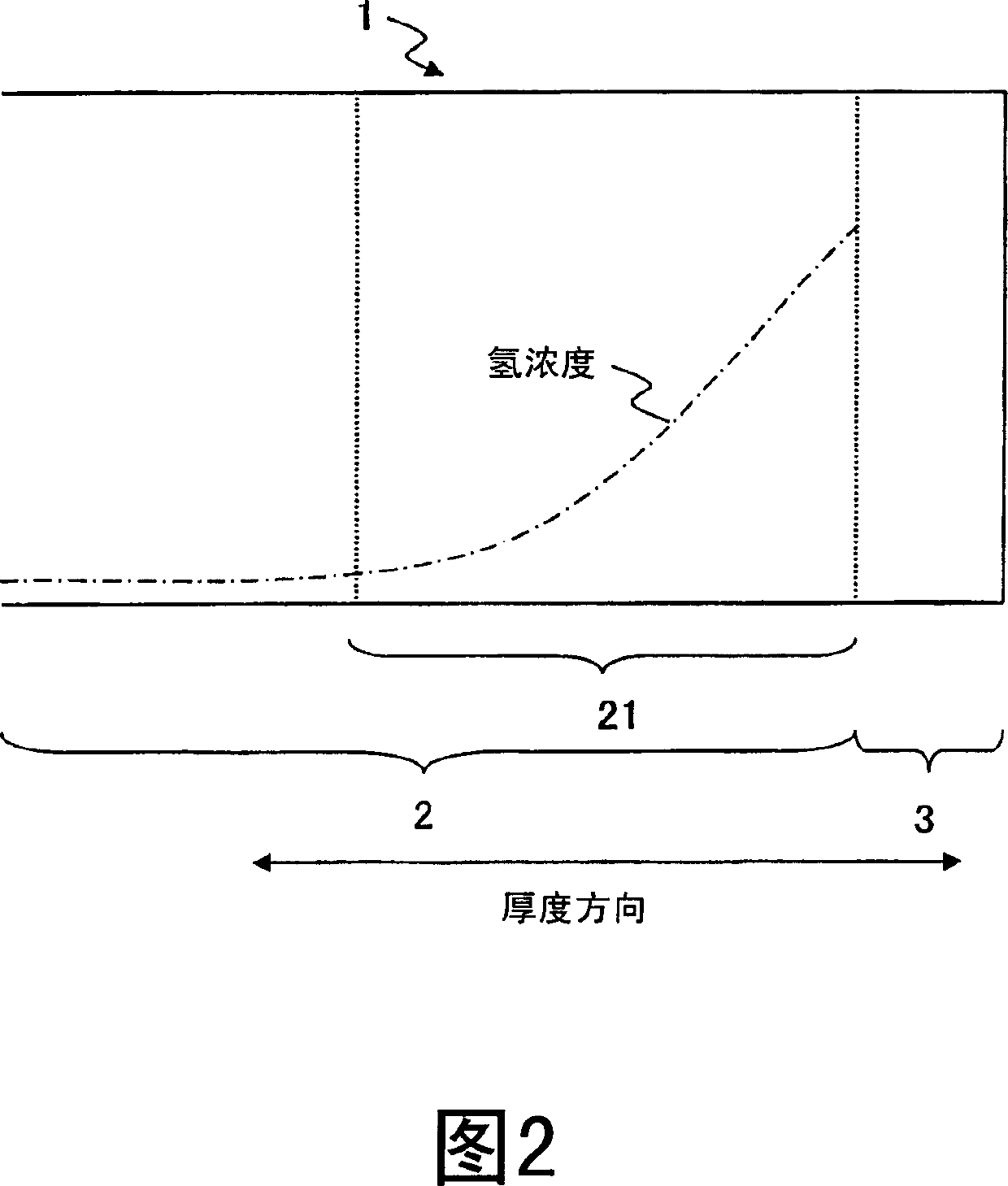

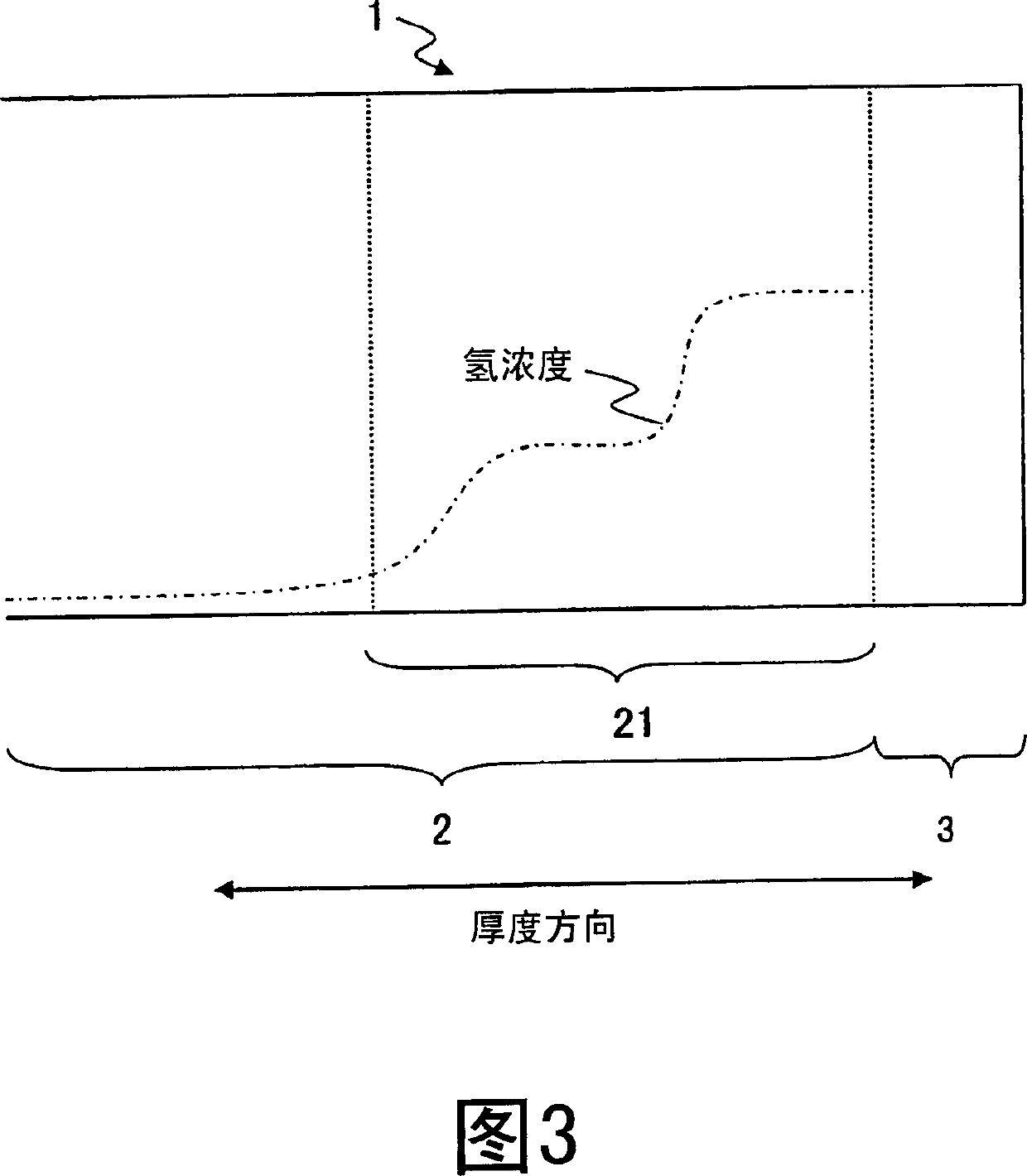

[0043] First, the hydrogen-rich layer which is the characteristic of the present invention will be described.

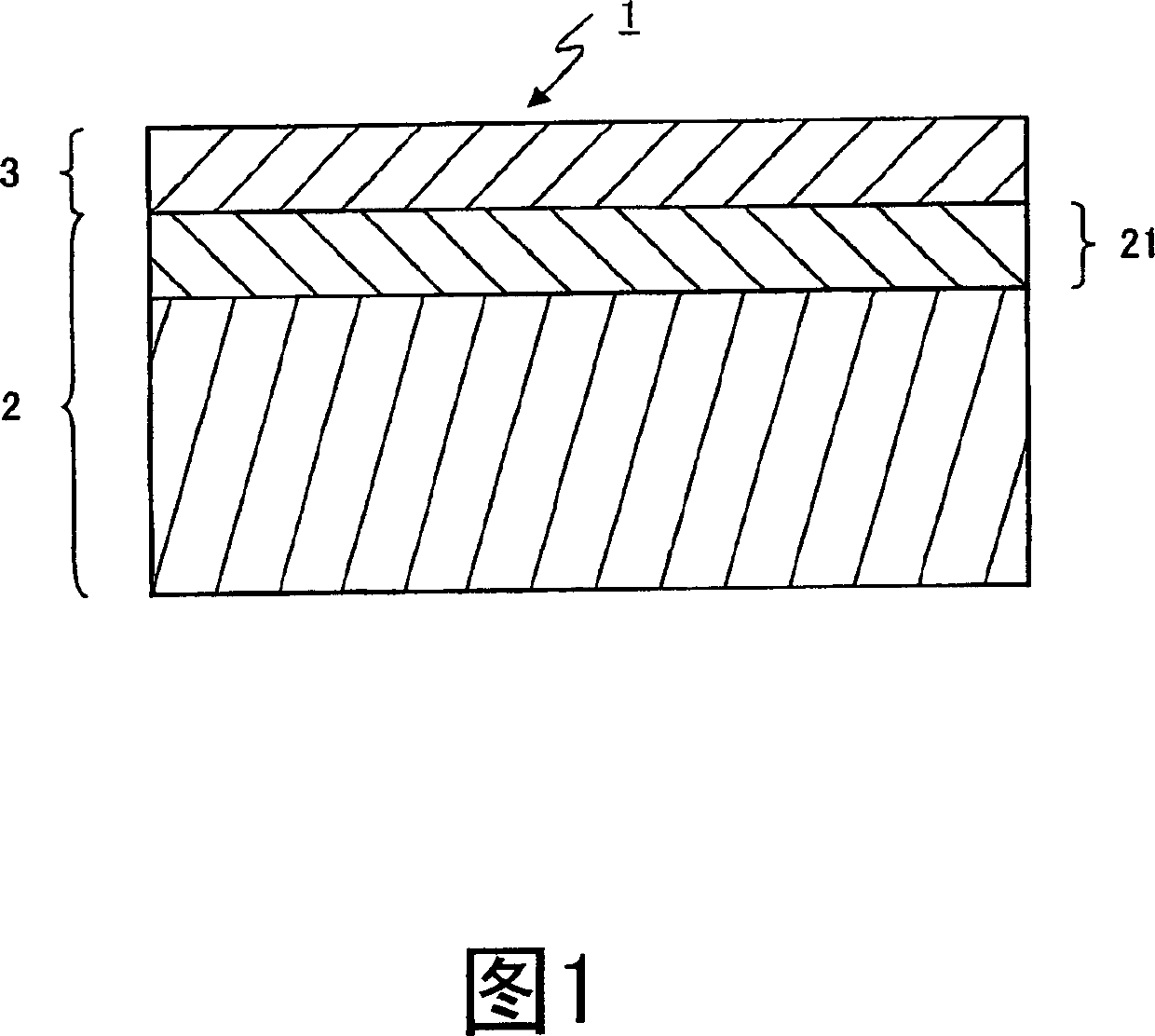

[0044] As shown in FIG. 1 , the R-T-B permanent magnet 1 of the present invention includes a magnet base 2 and a protective film 3 coated on the surface of the magnet base 2 . In addition, a hydrogen-rich layer 21 having a higher hydrogen concentration than the inside of the magnet base 2 exists on the surface portion of the magnet base 2 . Here, the hydrogen-rich layer means that the hydrogen concentration in the surface layer is higher than that in the magnet base 2 .

[0045] The hydrogen-rich layer 21 of the first aspect contains 300 ppm or more of hydrogen, and particularly the hydrogen-rich layer 21 of the 1-1 aspect contains 1000 ppm or more of hydrogen. The corrosion resistance is improved due to the presence of the hydrogen-rich layer 21 , but when the thickness of the layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com