Plasma device for production of metal powder

A metal powder, plasma technology, applied in the direction of plasma, electrothermal device, chemical/physical/physical-chemical process of applying energy, etc., can solve the problems of insufficient, reduced metal vapor, slowed carrier gas flow rate, etc., to achieve particle size Narrow distribution of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

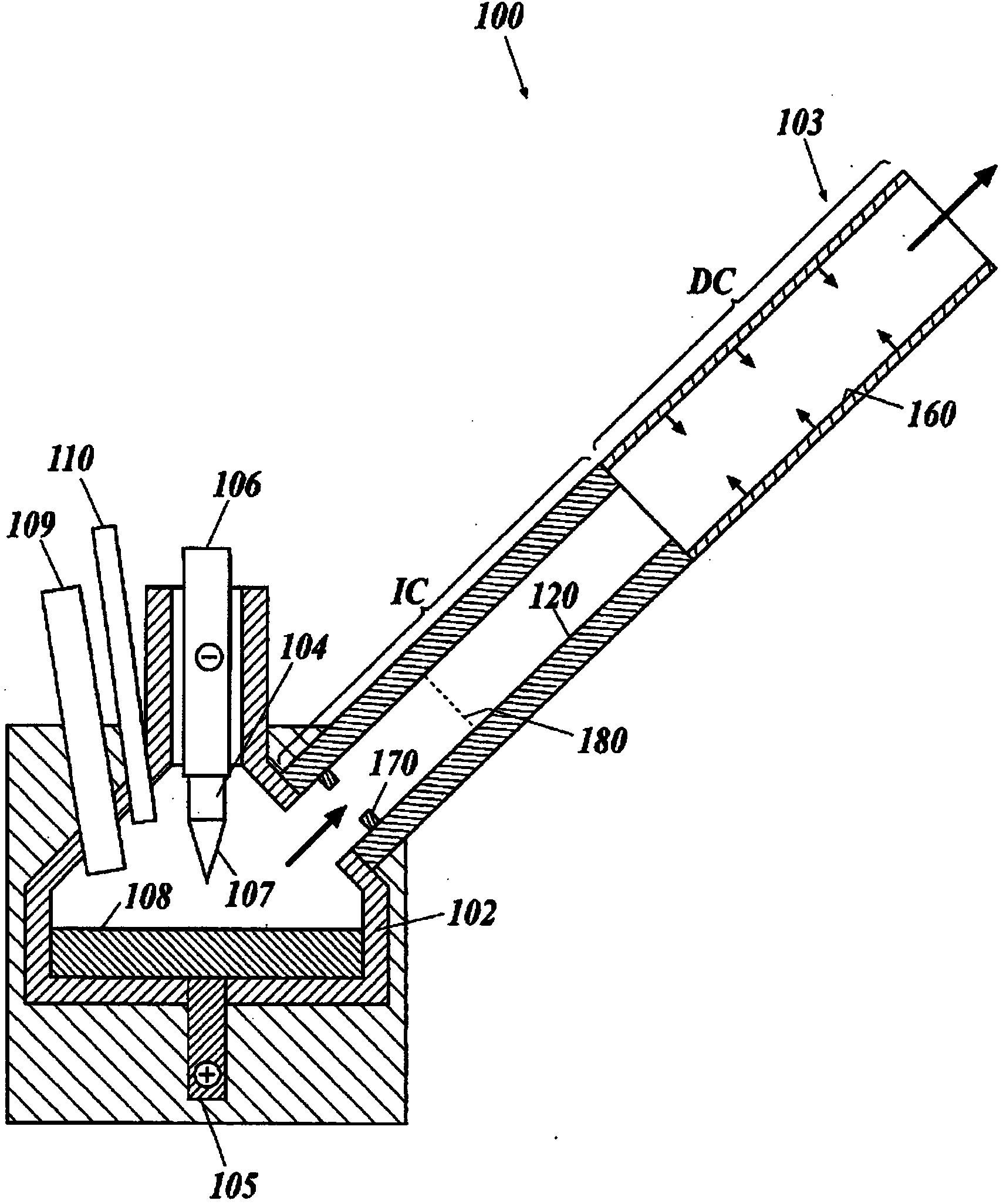

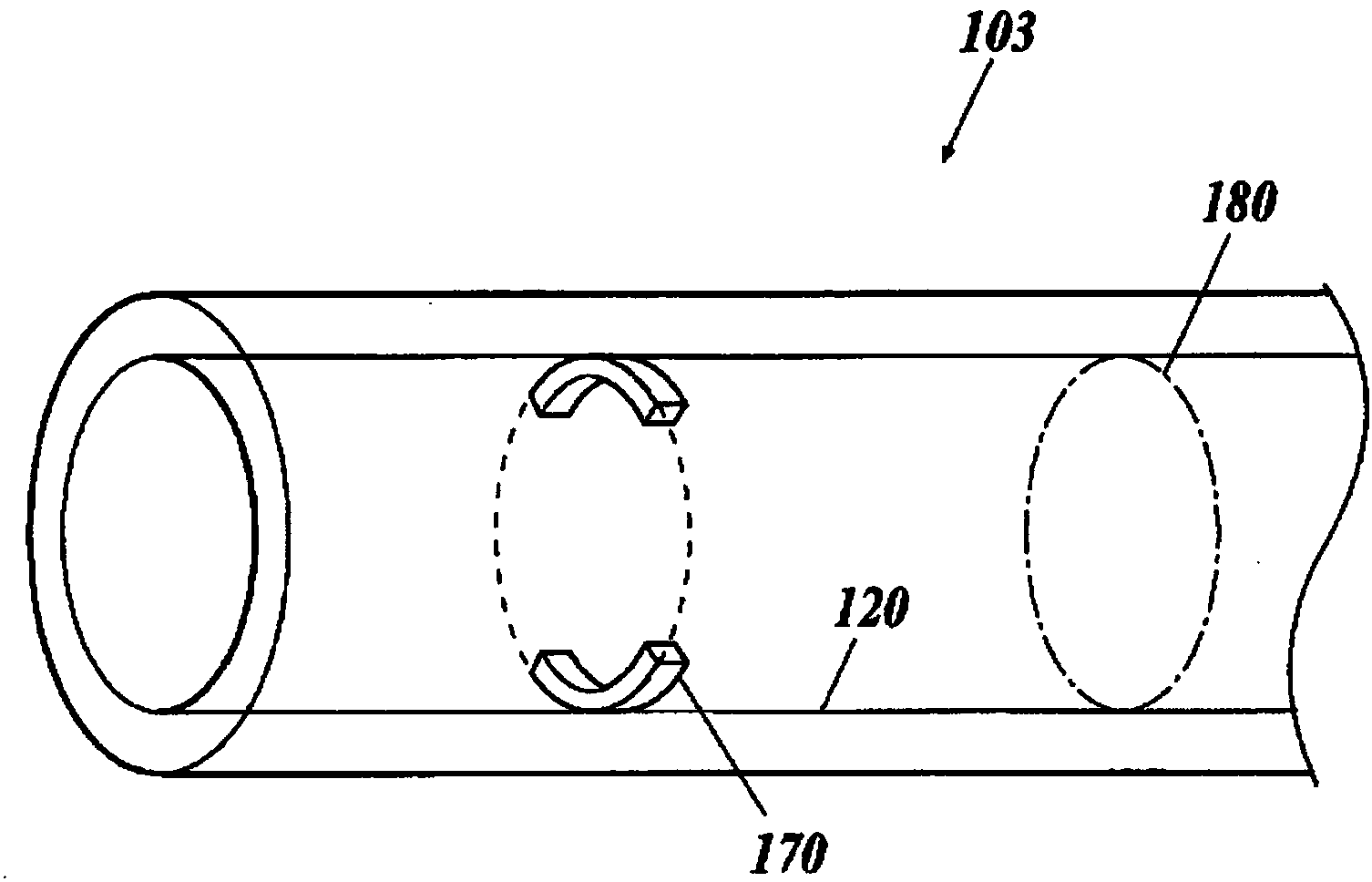

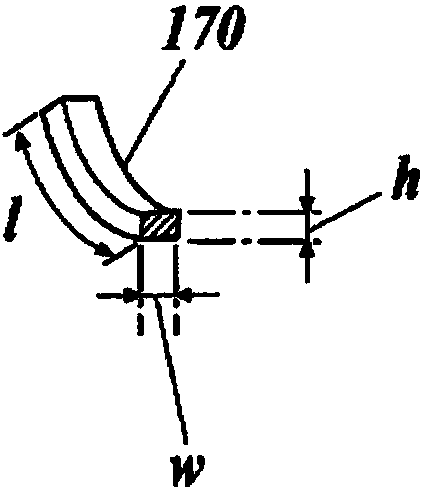

[0071] use Figure 2A and Figure 2B The cooling pipe 103 provided with the convex portion 170 described in figure 1 The described plasma apparatus 100 produces nickel powder. The cooling pipe 103 is a cooling pipe formed by combining an inner pipe 120 (indirect cooling area IC) with an inner diameter of 8 cm and a length of 115 cm and an inner pipe 160 (direct cooling area DC) with an inner diameter of 18 cm and a length of 60 cm. The inner wall of the tube 120 is provided with two convex portions 170 with a height (h) of 1 cm, a width (w) of 1 cm, and a length (l) of 5 cm at a position 20 cm away from the upstream end of the inner tube 120.

[0072] Controlled so that the carrier gas passing through the cooling pipe 103 passes 300L per minute, and the metal concentration is 2.1~14.5g / m 3 Range.

[0073] For the obtained nickel powder, the cumulative percentage 10% value, 50% value, and 90% value (hereinafter referred to as "D10", "D50", and "D90", respectively, based on the weig...

Embodiment 2

[0079] In addition to using Figure 5A and Figure 5B Except for the cooling pipe 103 provided with the convex portion 173 described, nickel powder was produced in the same manner as in Example 1. As the convex part 173, the cross section was a substantially equilateral triangle shape with a base (w) of 1 cm and a height (h) of 1 cm, and a plurality of squares with a length (l) of 3 cm were prepared. Furthermore, on the inner wall of the inner tube 120, a plurality of protrusions 173 span the entire area of the indirect cooling area IC so that the longitudinal direction of the protrusion 173 is at an angle of 45° with respect to the longitudinal direction (axial direction) of the cooling tube 103 Arranged into two spirals.

[0080] The nickel powder obtained in Example 2 is a powder with a narrow particle size distribution such as D50=0.44 μm and SD=1.10.

[0081] Based on the above results, compared with the nickel powder obtained in Comparative Example 1, the nickel powder obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com