Production method of yield strongth 460 MPa grade low alloy high strength structure steel plate

A low-alloy high-strength, yield-strength technology, applied in the field of low-alloy high-strength structural steel sheet manufacturing, can solve the problems of increased rolling mill load and energy consumption, high steelmaking cost, low finishing temperature, etc. Steel cost, high crack arrest performance, and the effect of reducing billet cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

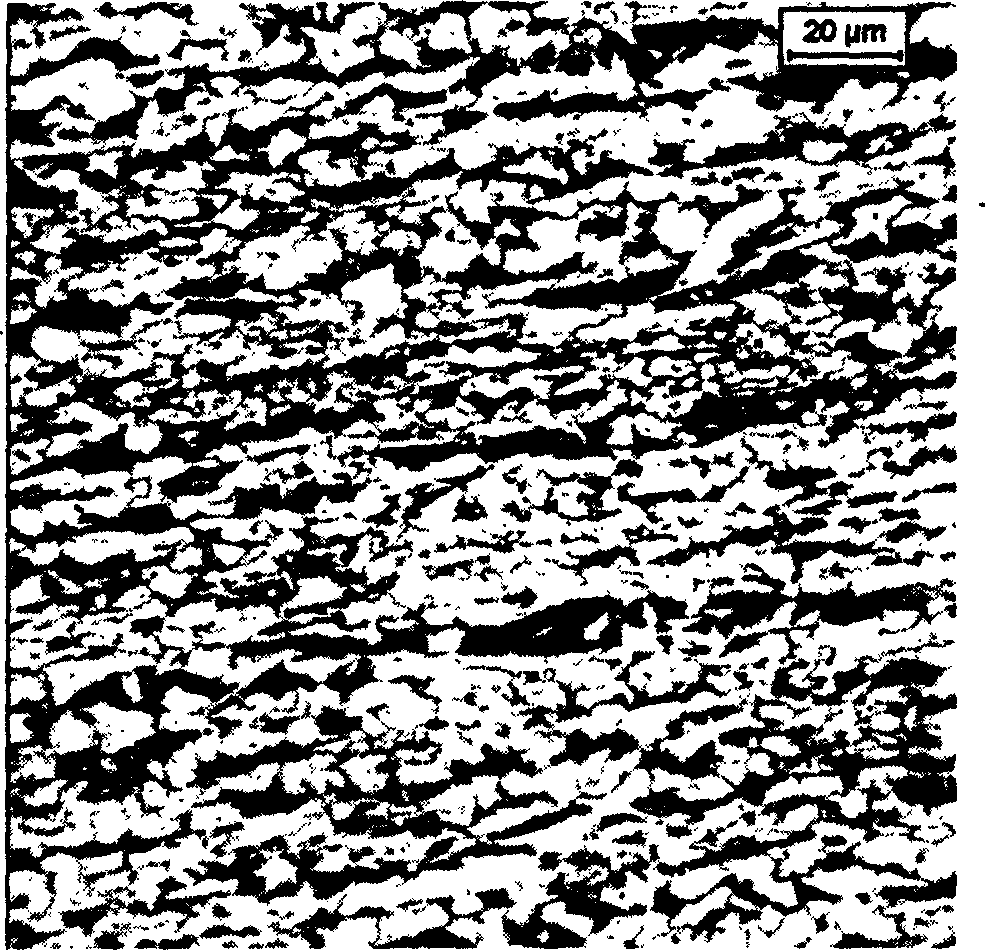

[0011] According to the chemical composition of the present invention, three batches of continuous casting billets from an industrial converter of a certain enterprise are used to produce square billets with a thickness of 100 × 90 × a length of 250 mm. The controlled rolling and cooling process is simulated on the experimental rolling mill, and the thickness specifications are respectively rolled. For steel plates of 12mm, 20mm and 30mm, each specification is an example, the sample numbers are 1, 2, and 3 respectively. The chemical composition is shown in Table 1 below, the controlled rolling and cooling process is shown in Table 2, and the mechanical properties are shown in Table 3. See you at the metallographic organization figure 1 .

[0012] Sample No

[0013] Sample code

[0014] Sample No

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com