Production method of hot-dip metal strip and device therefor

A technology of hot-dip metal and manufacturing method, which is applied in hot-dip plating process, metal material coating process, coating, etc., and can solve the problems of metal strip 1 dross adhesion, lower quality, lower production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

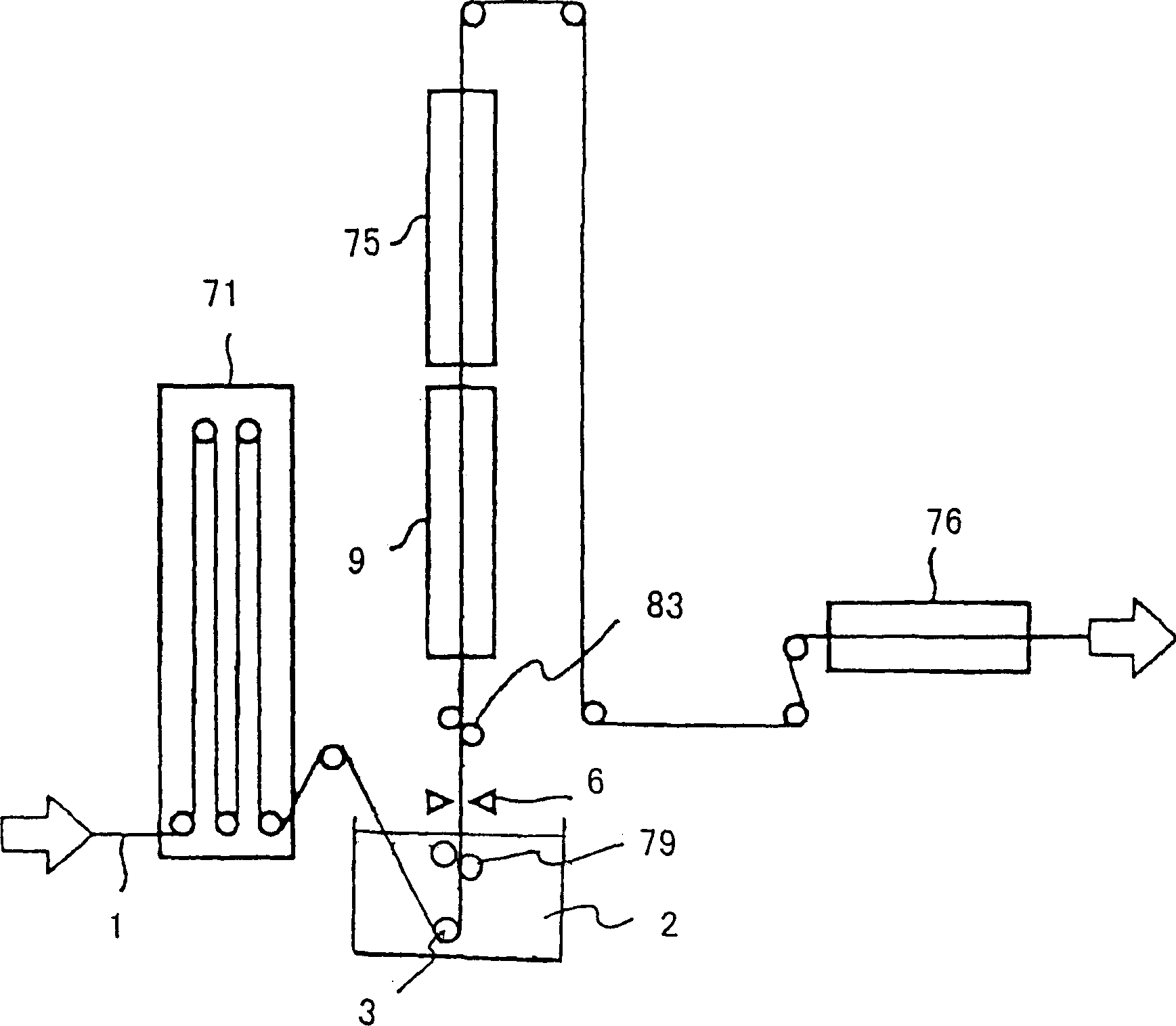

[0109] Figure 15 An example of the manufacturing apparatus of the hot-dip metal strip of this invention is shown.

[0110] A metal strip 1 is introduced into the molten metal bath 2 from a nozzle 4 kept in a non-oxidizing atmosphere, is redirected by synchronizing rollers 3 and drawn out above the molten metal bath 2 . The amount of molten metal deposited on the plating metal adhering to the metal strip 1 while moving in the molten metal bath 2 can be adjusted by the air brush 6 .

[0111] This device does not have the support roller in the molten metal bath 2 used in the conventional device, instead, at the position immediately behind the air brush 6, a metal strip shape using magnetic force and a Vibration control device7. The position immediately behind the air brush 6 referred to here refers to a position between the air brush 6 and an alloying furnace described later. If the metal strip shape and vibration control device 7 is close to the air brush 6, better shape con...

Embodiment 2

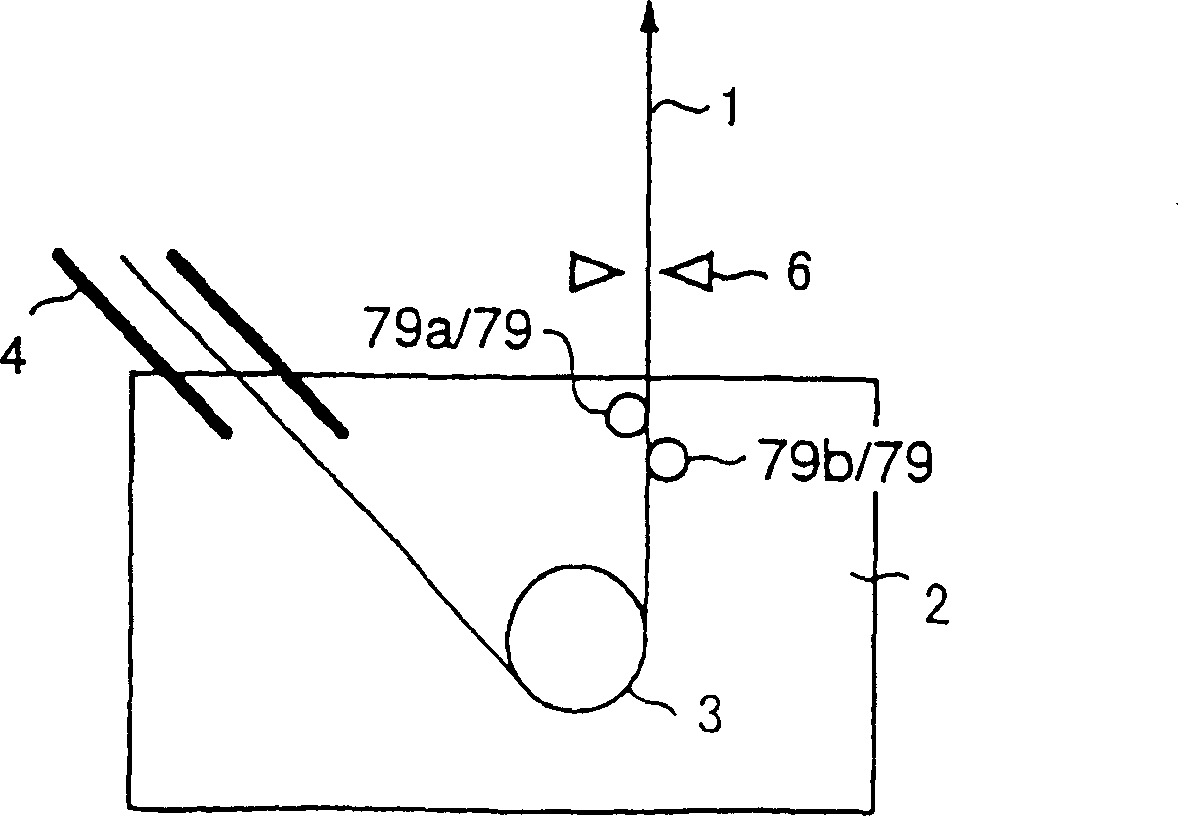

[0114] Figure 16 Another example of the manufacturing apparatus of the hot-dip metal strip of this invention is shown.

[0115] In this device, Figure 15 The metal strip shape and vibration control device 7 using magnetic force is provided at a position immediately in front of the air brush 6 without being in contact with the metal strip 1 . The immediately preceding position mentioned here refers to the position between the molten metal bath 2 and the air brush 6 . If the metal strip shape and vibration control device 7 is close to the air brush 6, better shape control can be achieved.

[0116] When the metal strip shape and the vibration control device 7 are arranged at any position immediately in front of or behind the air brush 6, the shape of the metal strip and the vibration control effect are the same, but when they are located at the position immediately in front or immediately behind the air brush 6, respectively It has the following advantages.

[0117] When it...

Embodiment 3

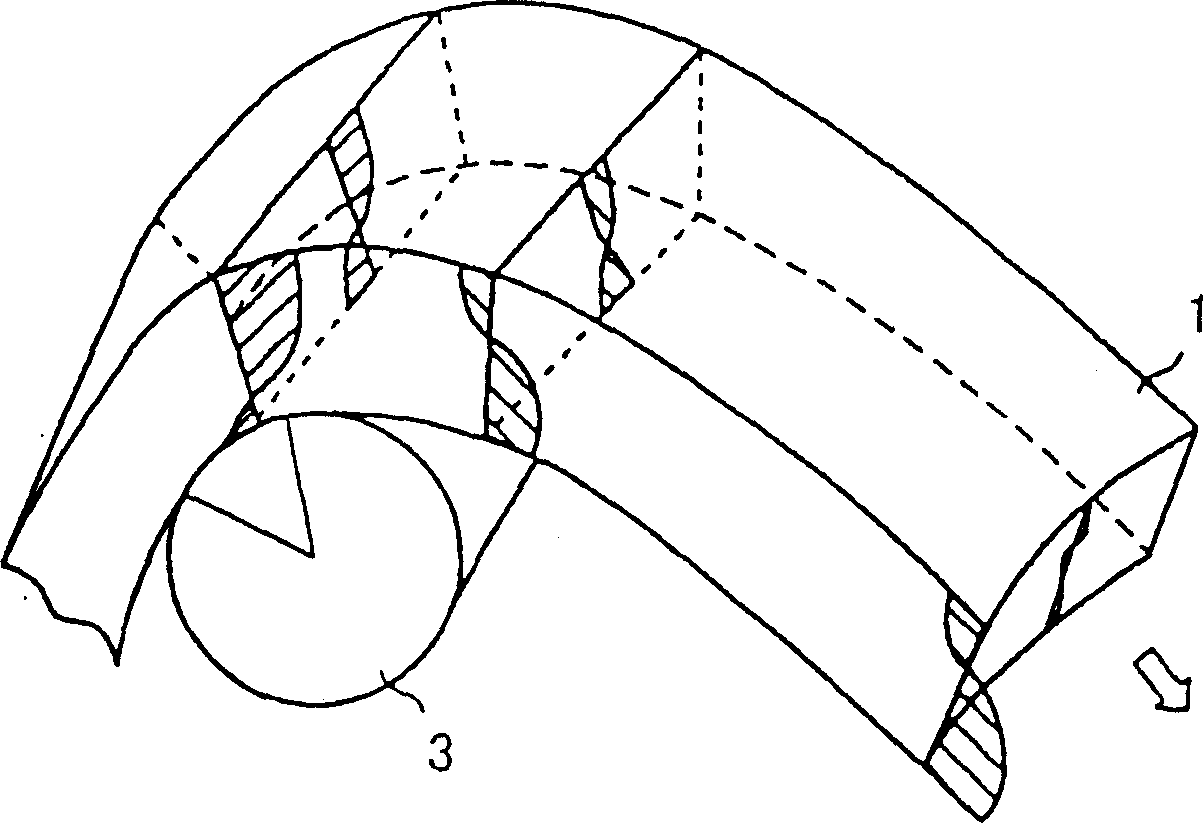

[0121] Figure 17A , 17B Another example of the manufacturing apparatus of the hot-dip metal strip of this invention is shown.

[0122]In this device, two strip-shaped and vibration control devices 7 using magnetic force are provided in a non-contact manner immediately behind the air brush 6 or immediately in front of and behind the air brush 6 .

[0123] Thus, by installing a plurality of metal strip shape control devices 7, it is possible to more effectively correct the shape or suppress vibration.

[0124] Generally, when the shape is corrected, since the shape change such as warping is slow, tracking performance is not required for the shape of the metal strip and the control system of the vibration control device 7 . On the other hand, when performing vibration control, since the vibration of the metal strip 1 changes rapidly, good sensitivity is required for the control system of the metal strip shape and the vibration control device 7 . In addition, the force require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com