Manufacturing method and manufacturing device for bundle product

A manufacturing method and manufacturing device technology, applied in the direction of measuring devices, chemical instruments and methods, transportation and packaging, etc., can solve the problems of unwinding, reduced manufacturing yield, and no use of operators, so as to ensure quality and production efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

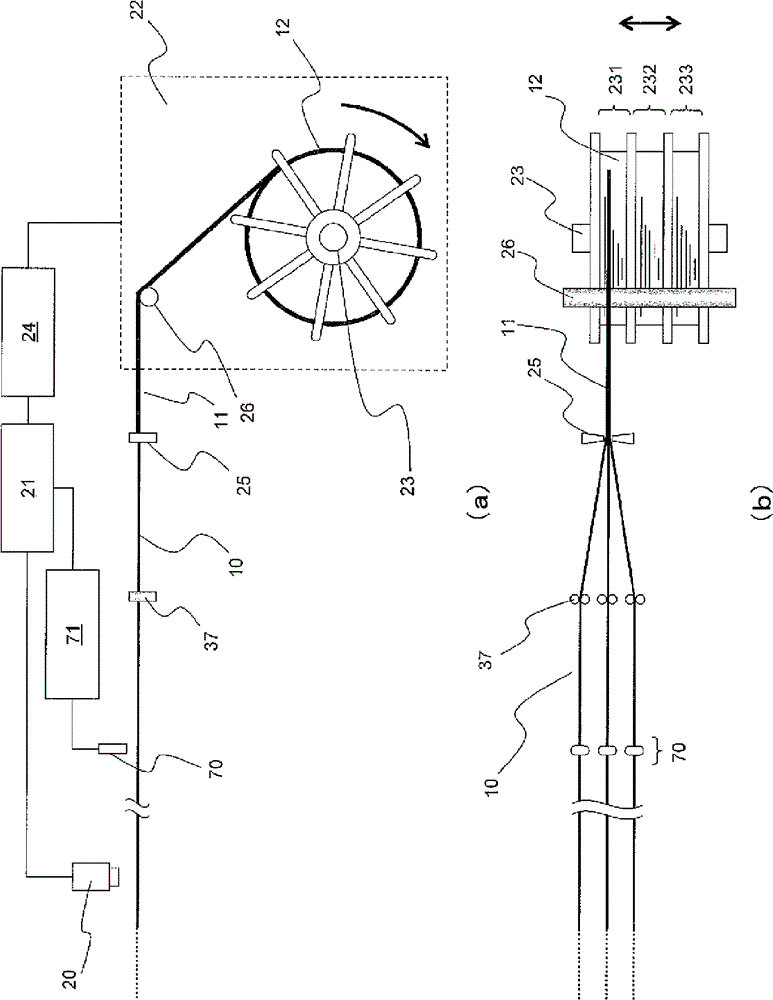

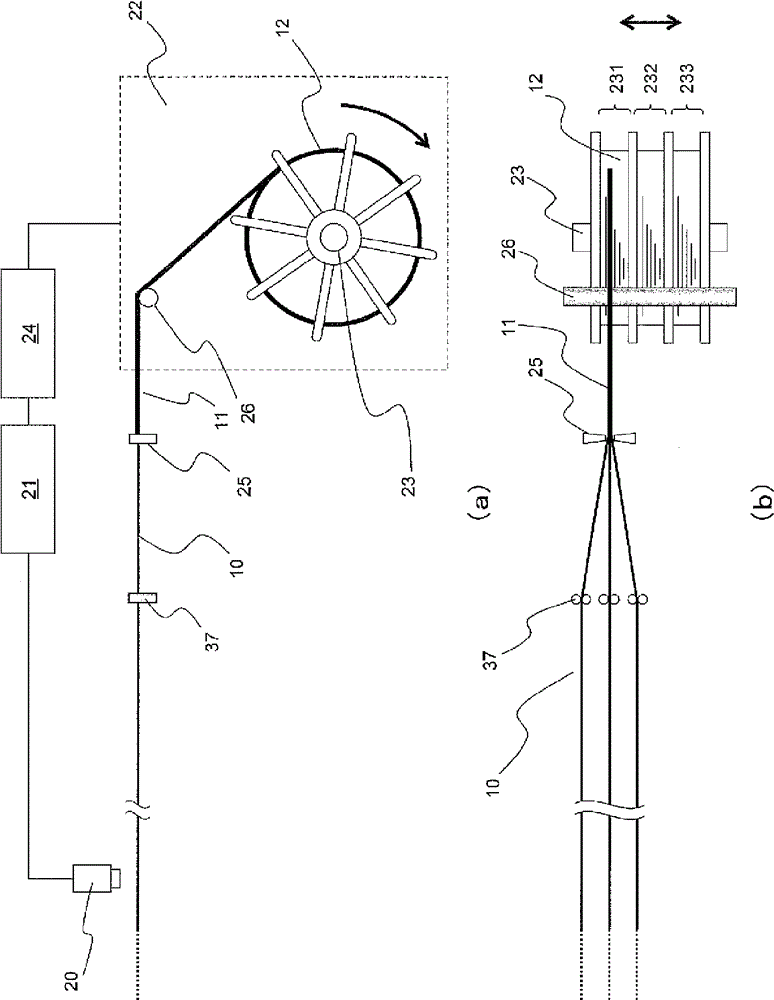

[0068] The first embodiment of the manufacturing apparatus of bundle-shaped products according to the present invention includes an inspection unit, a winding collection unit, a cutting unit, and a collection amount adjustment unit. figure 1 (a) (b) illustrate the embodiment of the inspection unit, the winding recovery unit, and the recovery amount adjustment unit by way of example, figure 2 (a)(b)(c) illustrate the embodiment of the cutting unit.

[0069] exist figure 1 (a) In (b), 10 is a monofilament of the hollow fiber membrane, 11 is a parallel-filament hollow fiber membrane formed by combining multiple monofilaments, 12 is a recovered parallel-filament hollow fiber membrane bundle, and 20 is measurement / inspection 21 is a measuring / checking control mechanism, 22 is a winding recovery device, 23 is a bobbin, 231, 232, and 233 are respectively the No. 1 position of the bobbin, the No. 2 position of the bobbin, and the No. 3 position of the bobbin. Winding recovery contr...

Embodiment approach 2

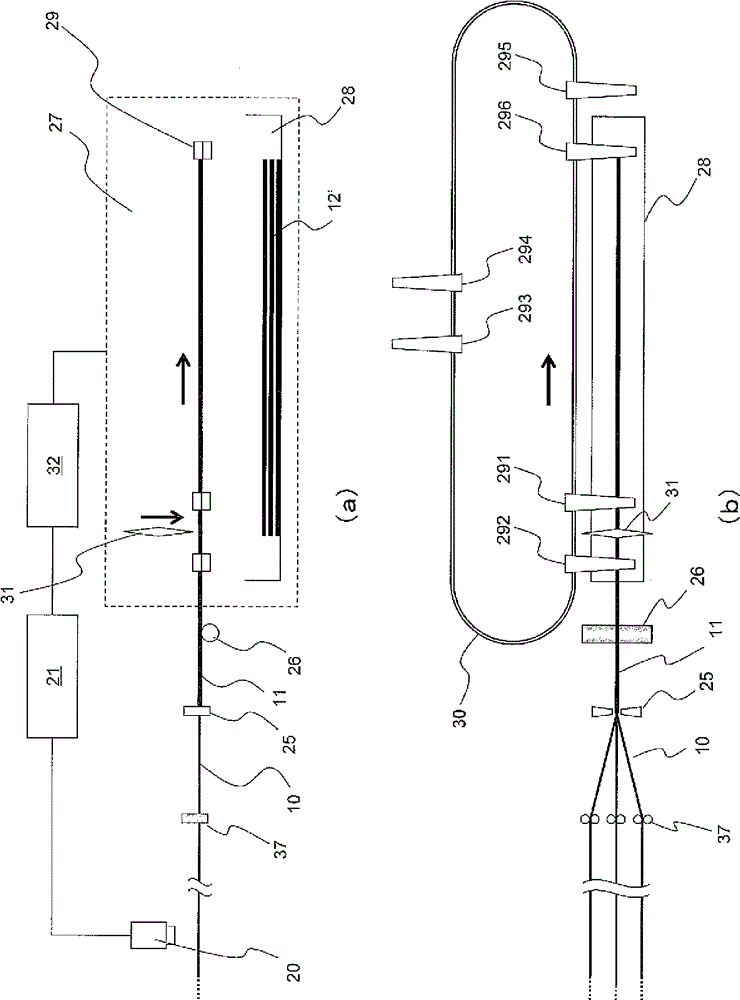

[0113] The second embodiment of the manufacturing apparatus of bundle-shaped products according to the present invention includes an inspection unit, a cut collection unit, and a collection amount adjustment unit. Figure 7 (a) and (b) illustrate the second embodiment. The inspection unit is composed of a measurement / inspection head 20 and a measurement / inspection control mechanism 21 similarly to the first embodiment. In addition, as will be described later, the recovery amount adjustment unit is constituted by the cut recovery control mechanism 32, and as the cut recovery unit, constitutes a cut recovery unit that cuts and recovers the thread while cutting it to a certain length.

[0114] Such as Figure 7 (a) As shown in (b), it is also possible to use a cut recovery device instead of the winding recovery device of the first embodiment as a recovery component. The doubling hollow fiber membrane 11 is cut into a given length by the cutting tool 31 and recovered to the reco...

Embodiment approach 3

[0120] The third embodiment of the manufacturing apparatus of bundle-shaped products of the present invention includes an inspection unit, a folding collection unit, a cutting unit, and a collection amount adjustment unit. Figure 8 (a) (b) The 3rd Embodiment is illustrated. The inspection unit is composed of a measurement / inspection head 20 and a measurement / inspection control mechanism 21 similarly to the first embodiment. In addition, as will be described later, the recovery amount adjustment unit is constituted by the return and return control mechanism 36, which serves as the return and return unit as a return and return unit that returns and returns the thread while returning it by a certain length.

[0121] Such as Figure 8 (a) As shown in (b), it is also possible to use a folding recovery device instead of the winding recovery device of the first embodiment as a recovery element. The doubling hollow fiber membranes 11 are returned to the rotating turnback gear 34 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com