Multi-pole magnetic ring of anisotropic bonded NdFeB and manufacturing method thereof

An anisotropic, multi-pole magnetic ring technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problems of destroying the uniformity of magnetic powder, long production cycle, and poor consistency of circumferential size, etc., to achieve demagnetization Adjustable magnetic field strength, short production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw material of magnetic powder used in production: 4-pole magnetic ring is prepared by using anisotropic HDDR-NdFeB magnetic powder. The specific experiments are as follows.

[0036] (1) Weigh 22g of epoxy resin, fully dissolve it in 150g of acetone, then add 1000g of magnetic powder, stir and heat to completely volatilize the acetone to obtain dry magnetic powder evenly coated with epoxy resin, and finally add 3g Molybdenum disulfide and 2g of EH-type enhanced lubricant are fully mixed to obtain pre-compressed magnetic powder;

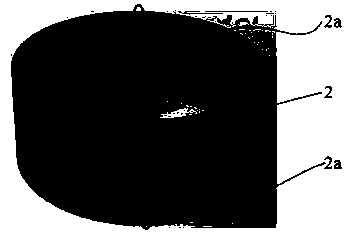

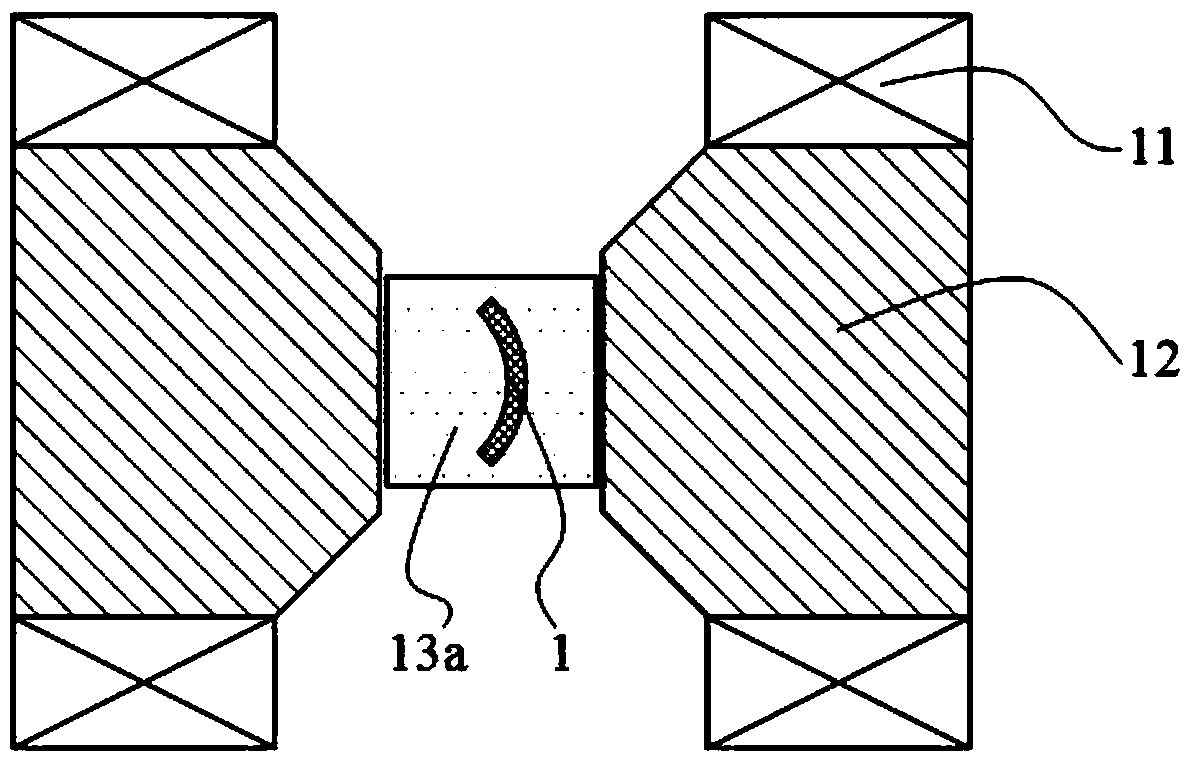

[0037] (2) Preheat the pre-compressed magnetic powder to 55°C in the hopper, and to 70°C in the material shoe. figure 1 with figure 2 The tile mold shown is preheated to 120°C, and the central angle of the tile mold is 89.9°±0.1°. Among them, by figure 1 with figure 2 It can be seen that the magnetic powder is in the tile-shaped cavity of the female mold 13a of the tile-shaped mold, and the two ends of the mold cavity are provided with ...

Embodiment 2

[0044] An 8-pole magnetic ring was prepared with anisotropic HDDR-NdFeB magnetic powder.

[0045] (1) Weigh 22g of epoxy resin, fully dissolve it in 150g of acetone, then add 1000g of magnetic powder, stir and heat to completely volatilize the acetone to obtain dry magnetic powder evenly coated with epoxy resin, and finally add 3g Molybdenum disulfide and 2g of EH-type enhanced lubricant are fully mixed to obtain pre-compressed magnetic powder;

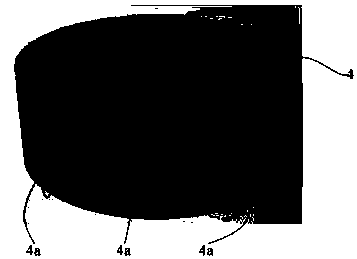

[0046] (2) Preheat the pre-compressed magnetic powder to 55°C in the hopper, and to 100°C in the material shoe. Image 6 The tile-shaped mold shown is preheated to 120°C, and the central angle of the tile-shaped mold is 44.9°±0.1°. Among them, by Image 6 It can be seen that the magnetic powder is in the mold cavity of the female mold 14a of the tile-shaped mold, and the die cavity two ends are provided with the concave mold 14b of the tile-shaped mold and the punch 14c of the tile-shaped mold that are slidably matched with the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface magnetism | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com