Kevlar nanofiber based high-strength heat conducting film preparation method

A nanofiber, thermally conductive film technology, applied in fiber types, fiber processing, chemical instruments and methods, etc., to achieve excellent thermal conductivity, simple method, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

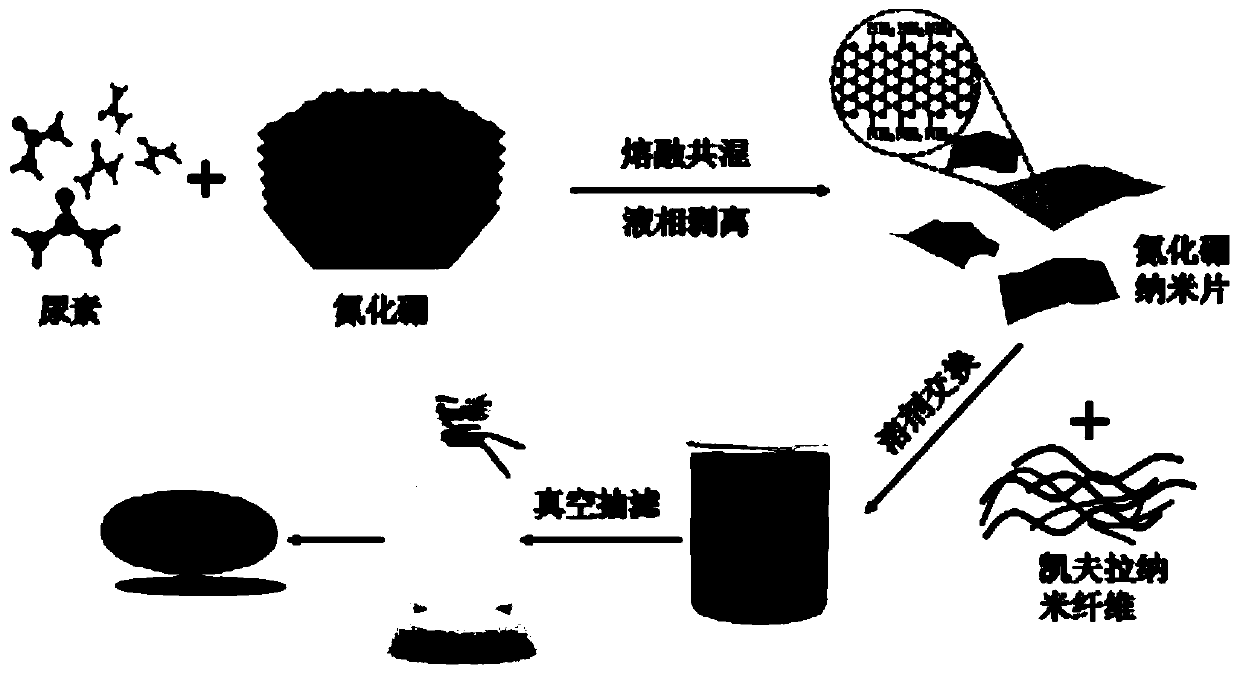

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of pure functionalized Kevlar nano film, the specific steps are as follows:

[0035] (1) Dissolve 1g of Kevlar and 1.5g of potassium hydroxide in 500mL of dimethyl sulfoxide solvent, heat in a water bath at 40-80°C, and stir for one week to obtain a Kevlar nanofiber / dimethyl sulfoxide dispersion ;

[0036] (2) Take 50mL of Kevlar nanofiber / dimethyl sulfoxide dispersion, add 2.5mL of phosphoric acid, 5mL of deionized water, and react at 90-110°C for 5h;

[0037] (3) centrifugal washing, remove dimethyl sulfoxide, disperse in deionized water;

[0038] (4) The filter membrane is an organic nylon filter membrane with a diameter of 50mm and a pore size of 0.45 μm, and vacuum filtration to obtain a boron nitride nanosheet / Kevlar nanofiber composite film, which is dried at 80°C for 24h;

[0039] (5) Take it out after drying, immerse in 3.5mL 50% glutaraldehyde solution, at 70°C for 40min, the functionalized Kevlar nanofiber membrane is obtained.

Embodiment 2

[0041] A preparation method of a composite film containing 5wt% boron nitride nanosheets, the specific steps are as follows:

[0042] (1) Calcining the boron nitride powder under nitrogen gas in a tube furnace at 1000°C for 3 hours;

[0043] (2) Take 1 g of calcined boron nitride powder and 6 g of urea in a round-bottomed flask, and heat it in an oil bath to 130° C. to 140° C. for 4 hours under nitrogen gas;

[0044](3) After the reaction is completed, disperse the solid in 500mL deionized water, and ultrasonically strip it for 8-12 hours. In this embodiment, ultrasonic treatment is performed for 10 hours, and then the dispersion is centrifuged at 3000rpm for 1 min to obtain a supernatant; Filtration and washing with deionized water, wherein the method of filtration is preferably suction filtration, and the collected solid is dried at 65° C. for 10 h to obtain urea-functionalized boron nitride nanosheets;

[0045] (4) Dissolve 1 g of Kevlar and 1.5 g of potassium hydroxide in...

Embodiment 3

[0052] A preparation method of a composite film containing 10wt% boron nitride nanosheets, the specific steps are as follows:

[0053] (1) Calcining the boron nitride powder under nitrogen gas in a tube furnace at 1000°C for 3 hours;

[0054] (2) Take 1 g of calcined boron nitride powder and 6 g of urea in a round-bottomed flask, and heat it in an oil bath to 130° C. to 140° C. for 4 hours under nitrogen gas;

[0055] (3) After the reaction is completed, disperse the solid in 500mL deionized water, and ultrasonically strip it for 8-12 hours. In this embodiment, ultrasonic treatment is 10 hours, and then the dispersion is centrifuged at 3000rpm for 10 minutes to obtain a supernatant; Filtration and washing with deionized water, wherein the method of filtration is preferably suction filtration, and the collected solid is dried at 65° C. for 10 h to obtain urea-functionalized boron nitride nanosheets;

[0056] (4) Dissolve 1 g of Kevlar and 1.5 g of potassium hydroxide in 500 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com