Method for Bionic Construction of Functionalized Janus Particles

A biomimetic construction and biomimetic function technology is applied in the field of preparation of Janus particles, which can solve the problems of lack of chemical reactivity on the surface of the product Janus particles, limiting the scope of preparation and use of Janus particles, and complex preparation processes, so that the preparation process can be easily controlled and enriched. Variety and function, stable effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

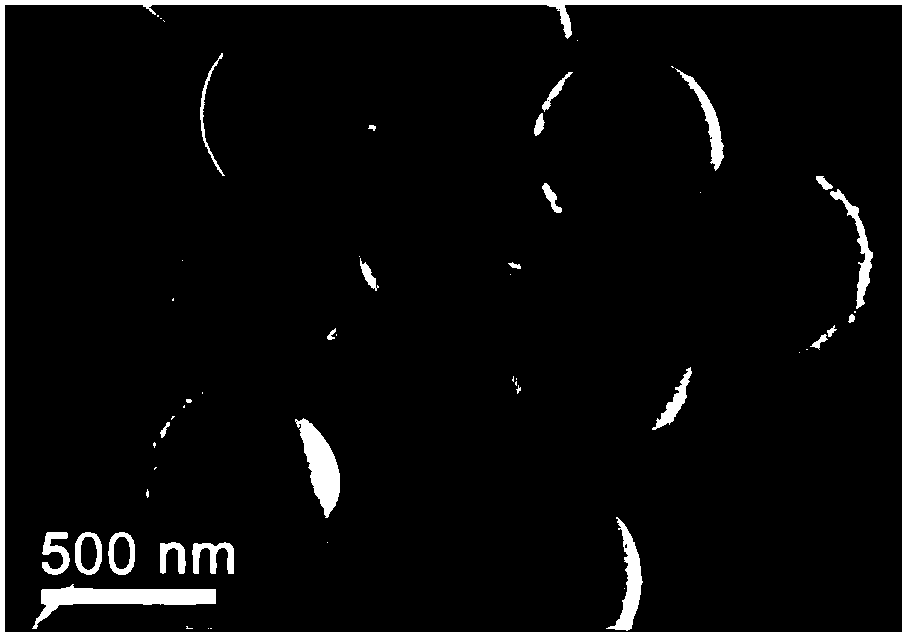

[0043] 1. Modified SiO2 2

[0044] 0.6g of SiO with a particle size of 520nm 2 Add microspheres into 30mL toluene, ultrasonically disperse evenly, then add 2.7g 3-aminopropyltriethoxysilane and 0.1g dimethyldichlorosilane, where SiO 2 The mass ratio of 3-aminopropyltriethoxysilane and dimethyldichlorosilane is 1:4.5:0.17, stirred at room temperature for 4 hours, and the reaction product is centrifuged, washed alternately with toluene and absolute ethanol, vacuum Dry to obtain the modified SiO 2 , and its water contact angle is 40.24°.

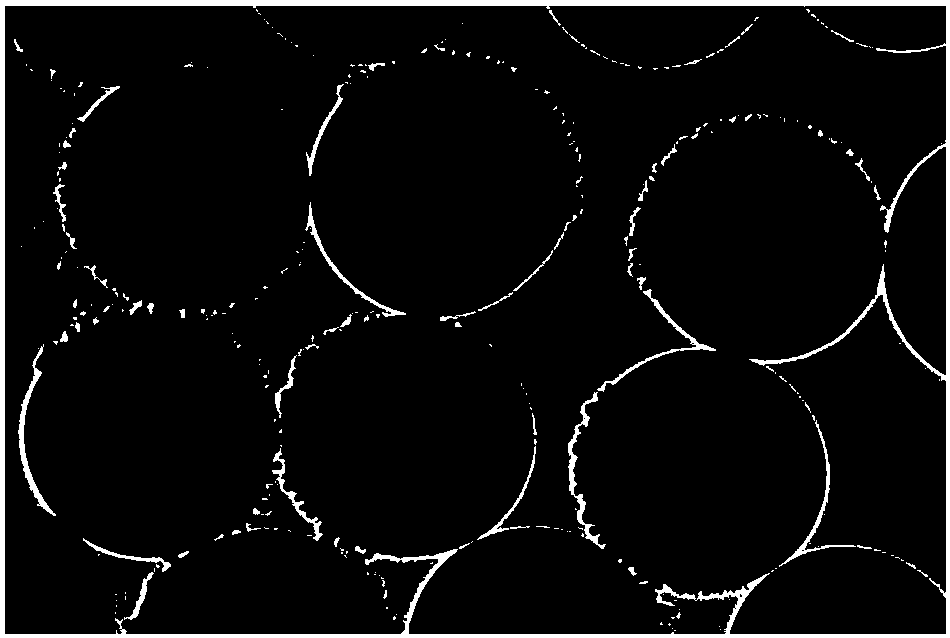

[0045] 2. Preparation of Pickering emulsion

[0046] 0.2g modified SiO 2 Add the microspheres into 10g of ultrapure water, ultrasonically disperse evenly, then place 1g of sliced solid paraffin on the upper layer of the dispersion, and heat the dispersion to 75°C. After the solid paraffin is completely melted, use a homogenizer at 9000 rpm Disperse for 3 minutes to form a Pickering emulsion.

[0047] 3. Preparation of biomimetic functi...

Embodiment 2

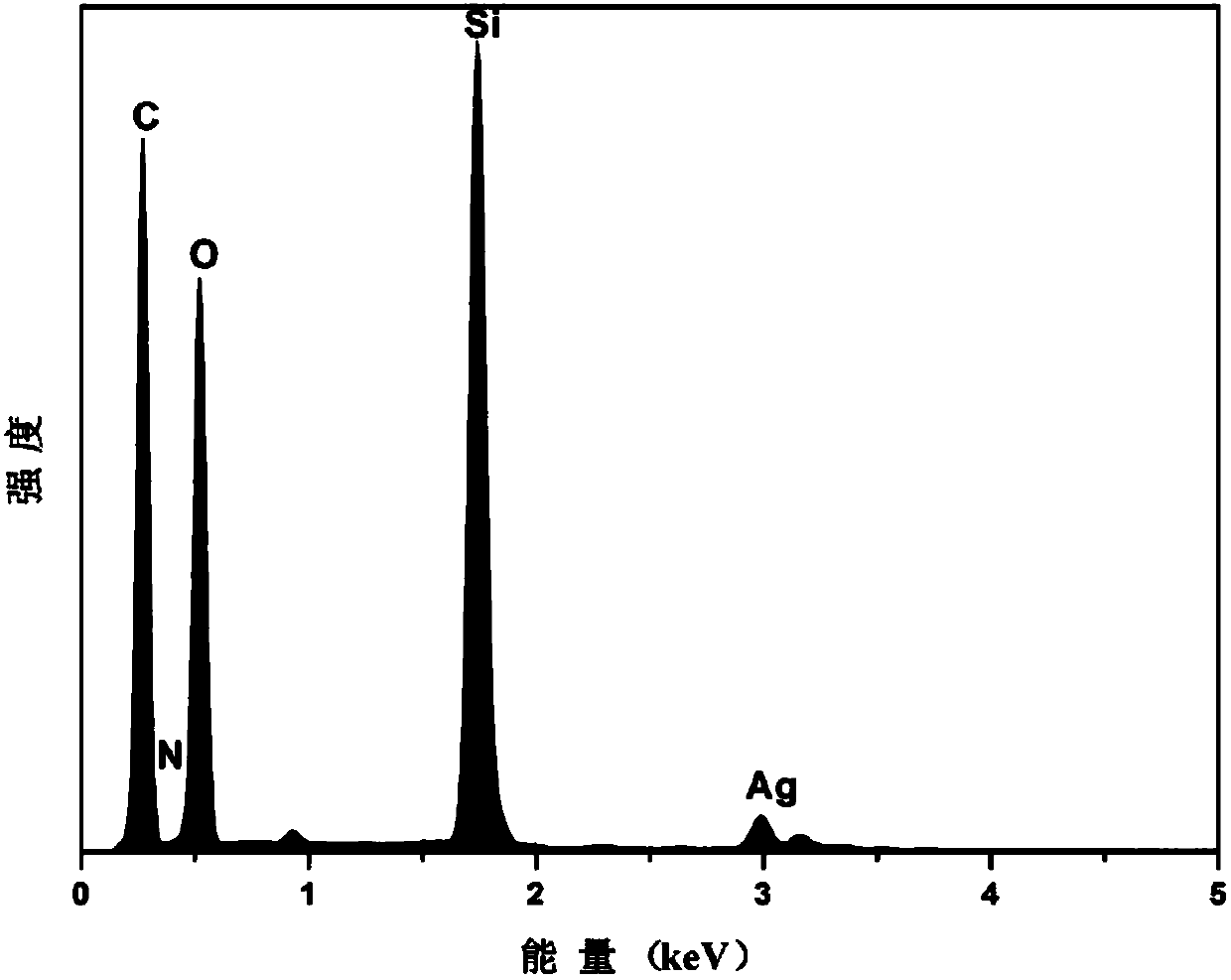

[0053] In step 1 of the present embodiment, 0.6g particle diameter is 520nm SiO 2 Add microspheres into 30mL toluene, ultrasonically disperse evenly, then add 2.7g 3-aminopropyltriethoxysilane and 0.1g dimethyldichlorosilane, where SiO 2 The mass ratio of 3-aminopropyltriethoxysilane and dimethyldichlorosilane is 1:4.5:0.17, stirred at room temperature for 4 hours, and the reaction product is centrifuged, washed alternately with toluene and absolute ethanol, vacuum Dry to obtain the modified SiO 2 , and its water contact angle is 40.24°. Other steps are identical with embodiment 1, obtain SiO 2 / Ag Janus particles (see Figure 5 ).

Embodiment 3

[0055] In step 1 of the present embodiment, 0.6g particle diameter is 520nm SiO 2 Add microspheres into 30mL toluene, ultrasonically disperse evenly, then add 2.7g 3-aminopropyltriethoxysilane and 0.3g dimethyldichlorosilane, in which SiO 2 The mass ratio of 3-aminopropyltriethoxysilane and dimethyldichlorosilane is 1:4.5:0.5, stirred at room temperature for 4 hours, and the reaction product is centrifuged, washed alternately with toluene and absolute ethanol, vacuum Dry to obtain the modified SiO 2 , and its water contact angle is 46.57°. Other steps are identical with embodiment 1, obtain SiO 2 / Ag Janus particles (see Image 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com