Automatic film coating apparatus for flat plate ceramic film, and flat plate ceramic film preparation method

A technology of coating device and ceramic membrane, applied in the field of water purification, can solve the problems that the outer surface is easily touched or polluted, affect the effective service life of the membrane, increase the frequency of replacing membrane elements, etc., and achieve high differential flow and consistent membrane thickness. , to avoid the effect of on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

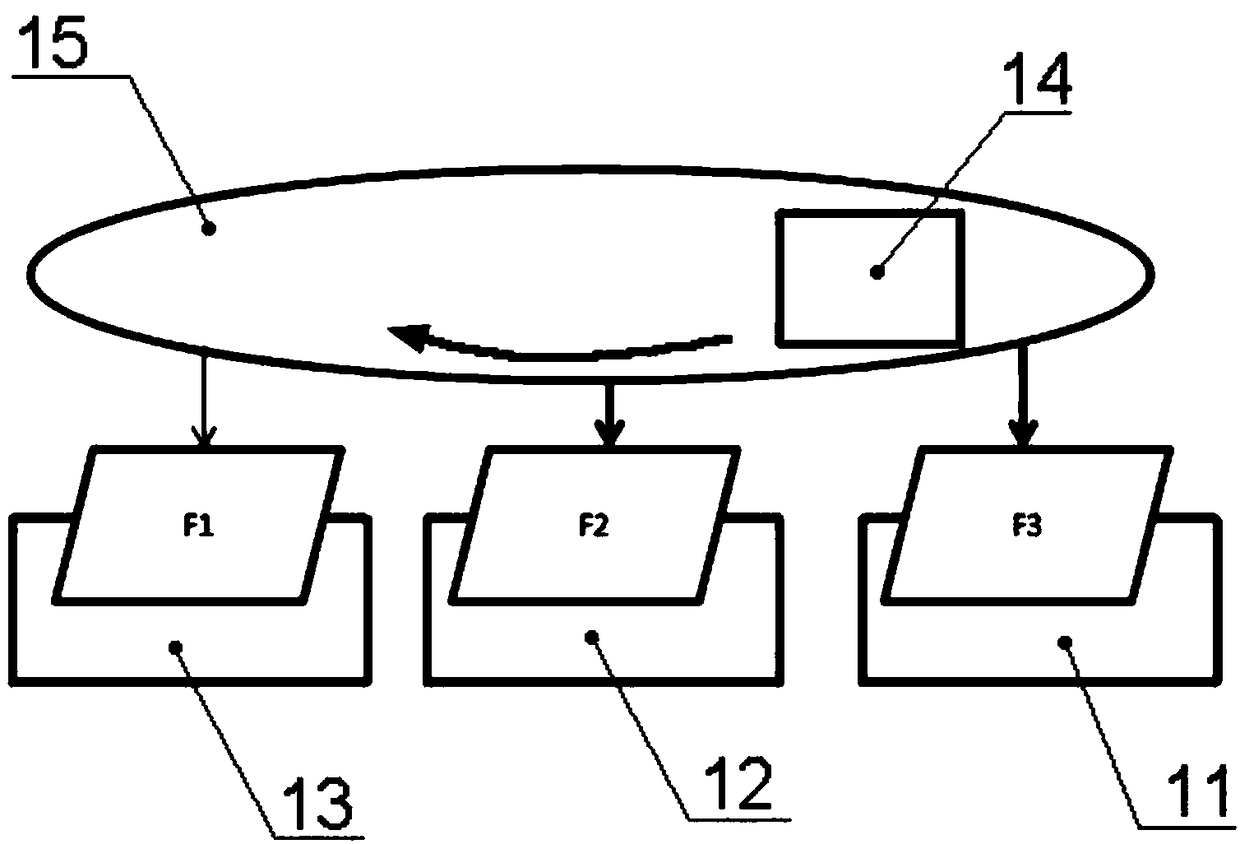

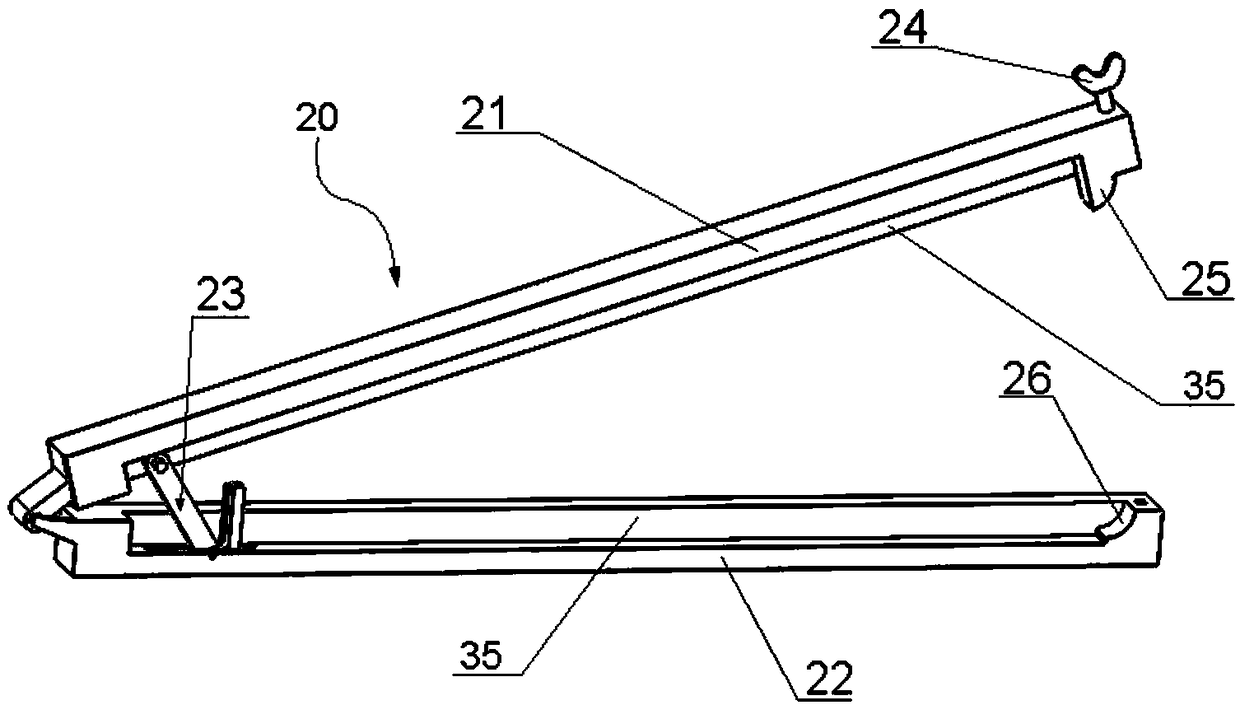

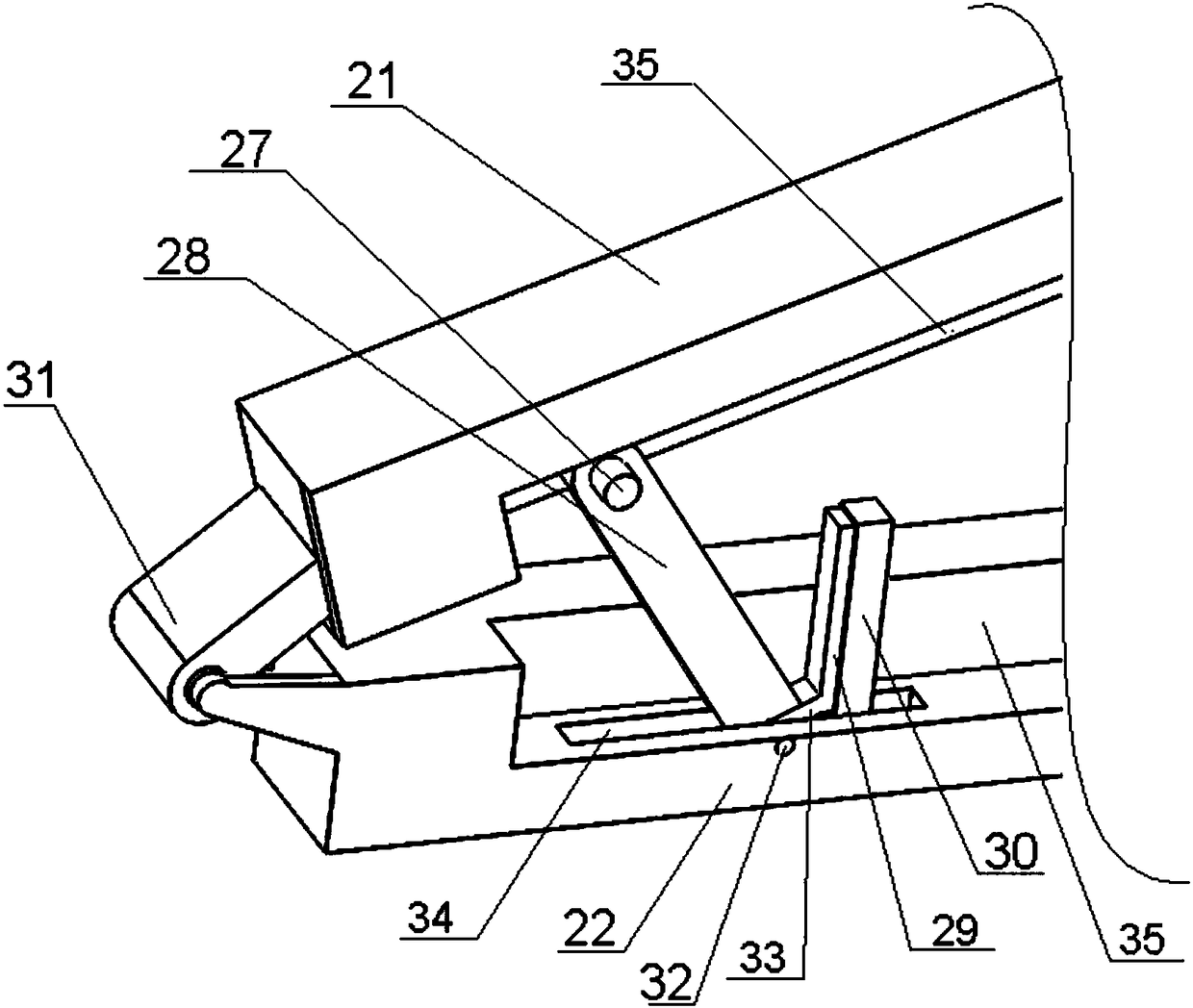

[0040] Such as Figure 1 to Figure 4 As shown, the automatic film coating device for flat ceramic film includes: a rotating track 15, a support body drying device 11, a film dipping tank 12, and a post-coating drying device 13.

[0041] figure 1 Among them, F1, F2 and F3 are the three states of the support body 10 during the film coating process, F1 is the bare support body; F2 is the flat ceramic film being coated; F3 is the flat ceramic film after coating.

[0042] The rotating track 15 drives the support body of the flat ceramic membrane to pass through the support body drying device 11 , the film dipping tank 12 and the post-coating drying device 13 in sequence.

[0043] The support body drying device 11 is used to pre-dry the uncoated support body. The drying temperature of the support body drying device 11 is 40-70°C.

[0044] The dipping tank 12 is filled with a coating solution, the support body 10 is immersed in the coating solution, and each outer surface is in co...

Embodiment 2

[0058] This embodiment provides a method for preparing a flat ceramic membrane using the device in Example 1.

[0059] 1) Put 20g of 1N nitric acid into 4000g of deionized water, stir at low speed for 3 minutes, slowly add 10 parts of 400g of alumina alumina (D50: 0.1μm-3μm) powder, stir at high speed for 20 minutes, slowly add 40g of PVA powder, and continue stirring 20 minutes.

[0060] 2) Put the prepared mixture into a vacuum device with a vacuum degree of 0.005MPa, and stir at a low speed for more than 20 minutes.

[0061] 3) Move the prepared mixture into the immersion film tank 12 of the automatic film coating device, and then start the automatic film coating device to carry out the film coating operation on the support body. The support body first passes through the support body drying device 11 for pre-drying, and then enters the Dip the slurry in the dipping tank 12, and then enter the post-coating drying device 13 for drying. In the above process, the time for dip...

Embodiment 3

[0065] This embodiment further provides a method for preparing a flat ceramic membrane using the device in Example 1.

[0066] 1) Put 40g of 1N nitric acid into 4000g of deionized water, stir at low speed for 5 minutes, slowly add 10 parts of 400g of alumina alumina (D50: 0.1μm-3μm) powder, stir at high speed for 30 minutes, slowly add 40g of PVA powder, and continue stirring 30 minutes.

[0067] 2) Put the prepared mixture into a vacuum device with a vacuum degree of 0.01 MPa, and stir at a low speed for more than 30 minutes.

[0068] 3) Move the prepared mixture into the immersion film tank 12 of the automatic film coating device, and then start the automatic film coating device to carry out the film coating operation on the support body. The support body first passes through the support body drying device 11 for pre-drying, and then enters the Dip the slurry in the dipping tank 12, and then enter the post-coating drying device 13 for drying. In the above process, the time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com