Heat exchange vertical kiln

A shaft kiln and cylinder technology, which is applied in the directions of preheating, waste heat treatment, lighting and heating equipment, etc., can solve the problem of large selection of dust collectors and induced draft fans, increase power consumption and cost of production and operation, and increase bag type dust collectors. and investment in induced draft fans to achieve the effect of low airflow speed, quality assurance, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

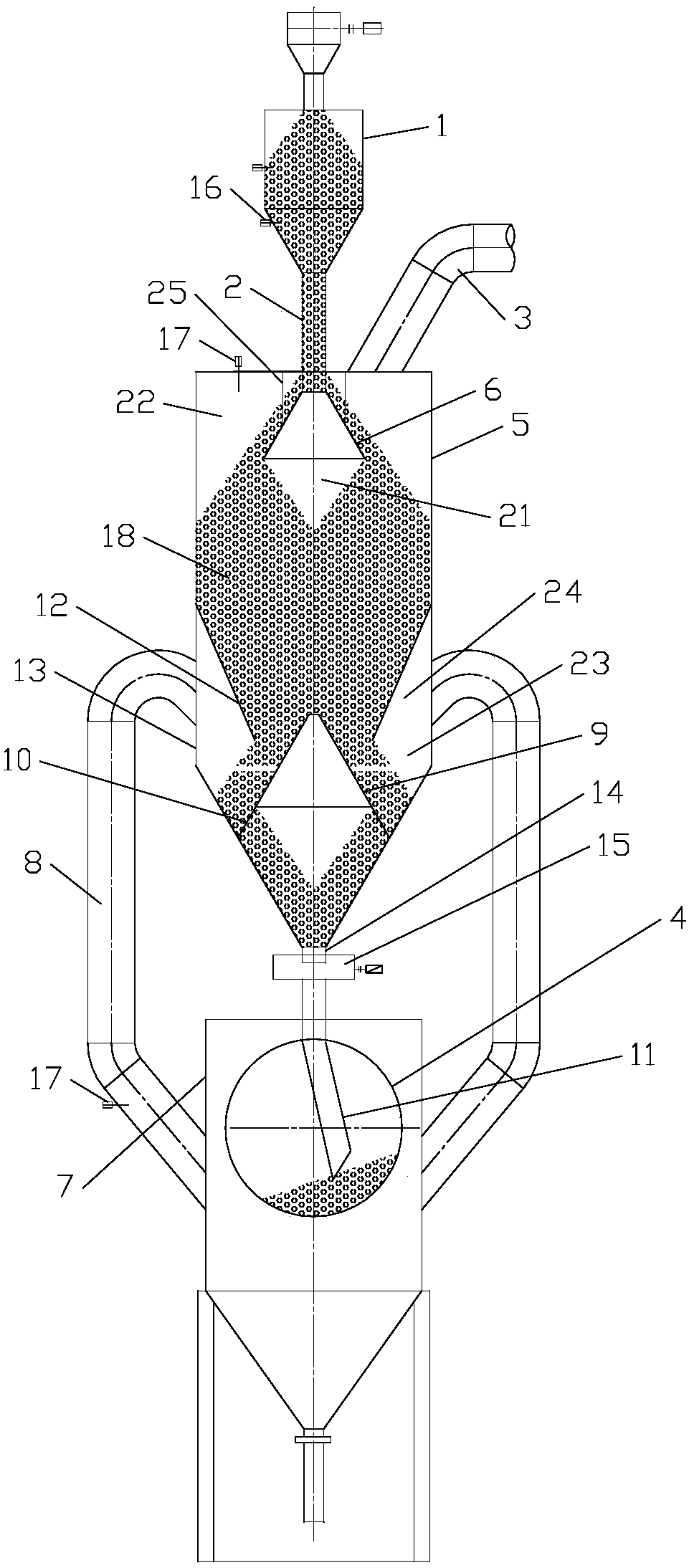

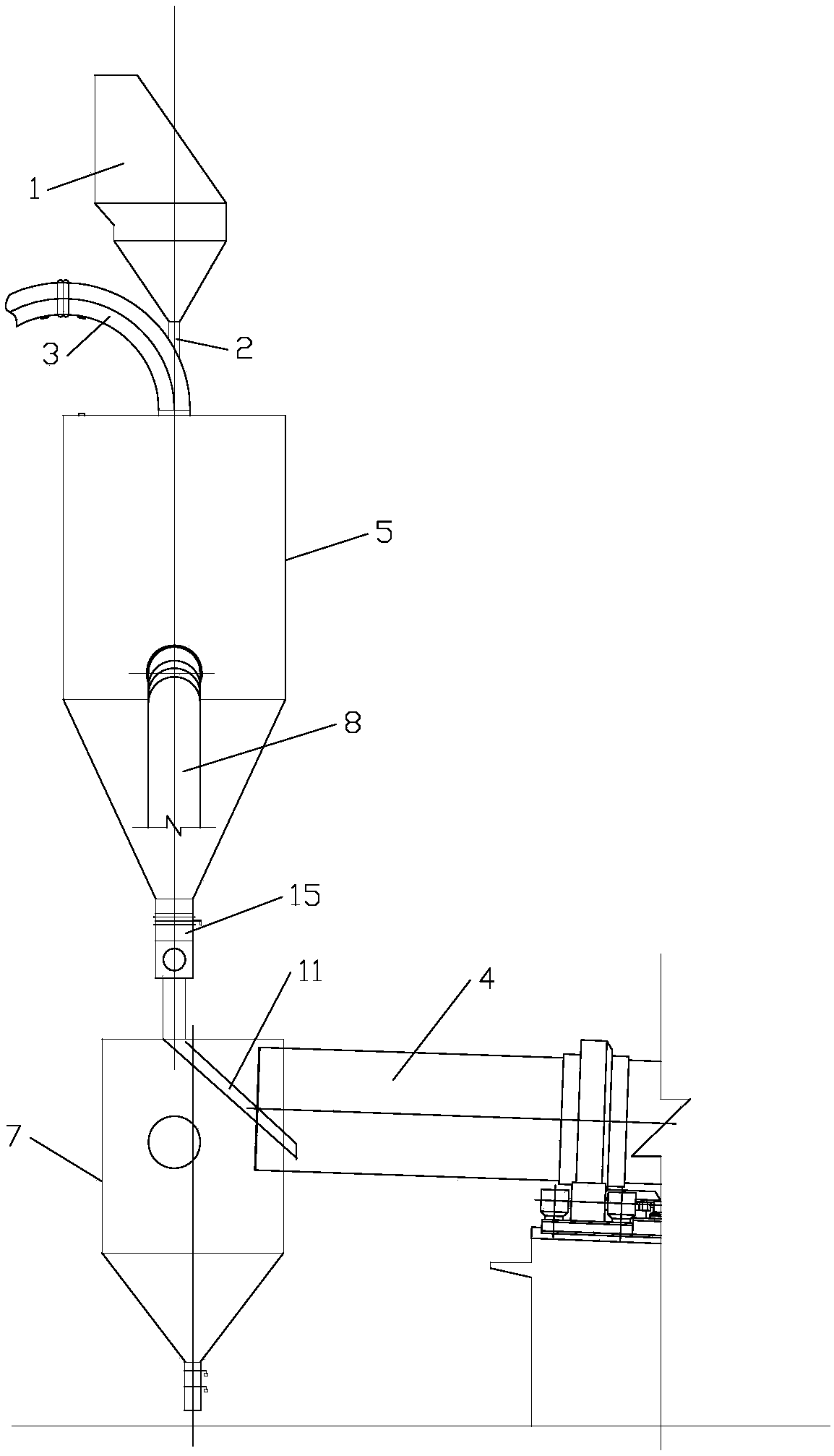

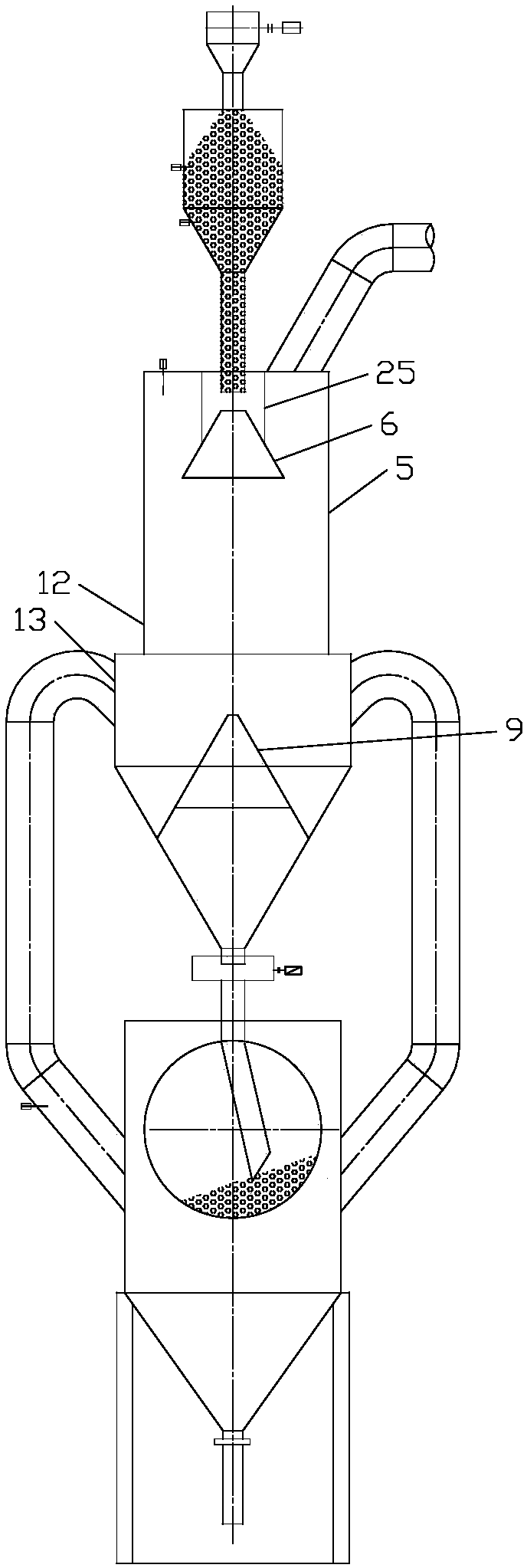

[0028] For the convenience of explanation, the preheater is used as an example for illustration. see figure 1 , 2 In the vertical preheater for preheating limestone, the upper part of the cylinder 5 is provided with a feeding bin 1, a feeding pipe 2 and a distributor 6 for adding materials 18 into the cylinder. The feeding bin 1 is provided with two material level detection devices 16 for detecting height. The outlet end of the feeding pipe is located at the center of the top of the cylinder and communicates with the inside of the cylinder, and the distributor is located below the outlet of the feeding pipe. The feeding pipe 2 can be stretched relative to the cylinder to change the length (equivalent to the feeding pipe can move up and down relative to the cylinder). The distributor 6 is a conical body with a small upper part and a larger lower part. It is suspended on the top of the upper cylinder by a suspension cable or a suspender 25. The suspension cable or suspender 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com