A kind of hydrophilic diisocyanate and its preparation method and application

A diisocyanate and hydrophilic technology, applied in the field of polyurethane, can solve the problems of poor fat solubility, high price, and inability to extend the chain of isocyanate, and achieve the effects of stable performance, simple method and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

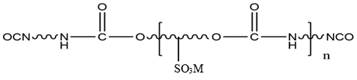

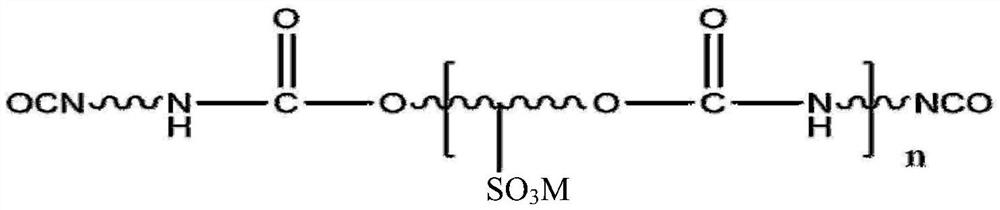

Method used

Image

Examples

preparation example Construction

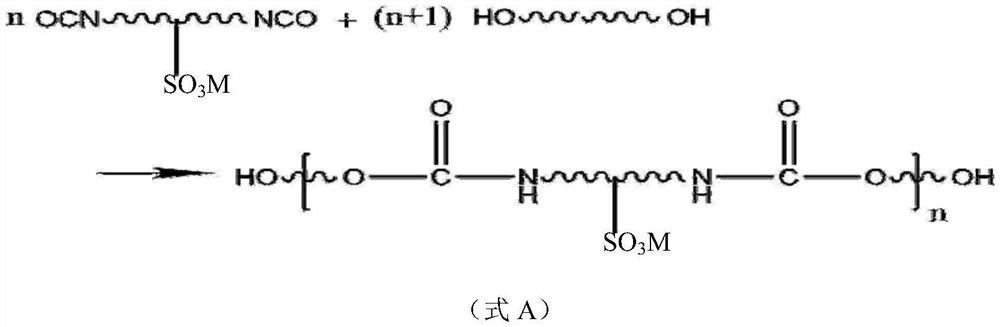

[0061] A kind of preparation method of hydrophilic diisocyanate, comprises the following steps:

[0062] In the reaction kettle, add diisocyanate and co-solvent, turn on the agitator, raise the temperature to 30°C-80°C, add the hydrophilic chain extender in several times, each time after adding the hydrophilic chain extender, it should be at 50°C-60°C React for 0.5-3 hours until the last addition of the hydrophilic chain extender, react at 50°C-60°C for 0.5-3 hours, then raise the temperature to 60°C-80°C and react for 6-20 hours, cool down and discharge to obtain hydrophilic permanent diisocyanate.

[0063] The above-mentioned hydrophilic chain extender is divided into 3-10 parts, and then added in several times. After each part of the hydrophilic chain extender is added, it must be reacted at 50-60°C until the liquid in the kettle is transparent.

[0064] The molar ratio of the reaction materials is diisocyanate:hydrophilic chain extender (3-4):1.

[0065] The above-mentio...

Embodiment 1

[0092] A kind of preparation method of hydrophilic diisocyanate, comprises the following steps:

[0093] a) Preparation of hydrophilic chain extender (small molecule sulfonate diol)

[0094] In the reaction flask equipped with a fractionation device, add 150g of diethylene glycol, 780g of 1,4-butanediol, 260g of deionized water, 2.4g of triphenyl phosphite, turn on the stirrer, raise the temperature to 95°C, and add 400g of m-benzene Diformic acid-5-sodium sulfonate, dissolved at 90-95°C for 2 hours; add 360g of adipic acid, stir at 90-95°C until completely dissolved, then pass nitrogen gas to start esterification reaction, raise the temperature in the kettle, Control the temperature of the water outlet at the top of the condenser tube to 90-99°C. With the progress of the esterification reaction, the temperature in the kettle is controlled at 160-190°C. When the water output reaches the theoretical value, continue to output water for 1 hour; turn on the vacuum pump to graduall...

Embodiment 2

[0098] Preparation of hydrophilic diisocyanate (hydrophilic MDI) comprises the following steps:

[0099] In the reaction bottle, add 200g (1.6 equivalent) of MDI and 67g of acetone, turn on the agitator, raise the temperature to 30°C, take 67.2g (0.32 equivalent) of the hydrophilic chain extender prepared in step a) of Example 1 and add it in four times , react for 0.5 hours after each addition, until all the addition is completed. After 1 hour of reaction, raise the temperature to 50°C for 2 hours, and then rise to 60°C. After 5 hours of reaction, take samples every 0.5 hours to measure the NCO content. When it is stable, the temperature is lowered and discharged to obtain MDI containing sulfonate groups with a solid content of 80%.

[0100] The viscosity of the hydrophilic MDI is 5600mPa.s / 25°C, the NCO% is 16.0%, and the storage period is 6 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com