Device for in situ extraction of a substance comprising hydrocarbons

a technology of hydrocarbon extraction and in situ extraction, which is applied in the direction of fluid removal, insulation, borehole/well accessories, etc., can solve the problems of reducing the thermal energy introduced into the storage site, reducing the operation reliability of the electric heater, and reducing the volume of the storage site. , to achieve the effect of increasing the electrical conductivity of the storage site, improving the reliability of the electric heater, and improving the reliability of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

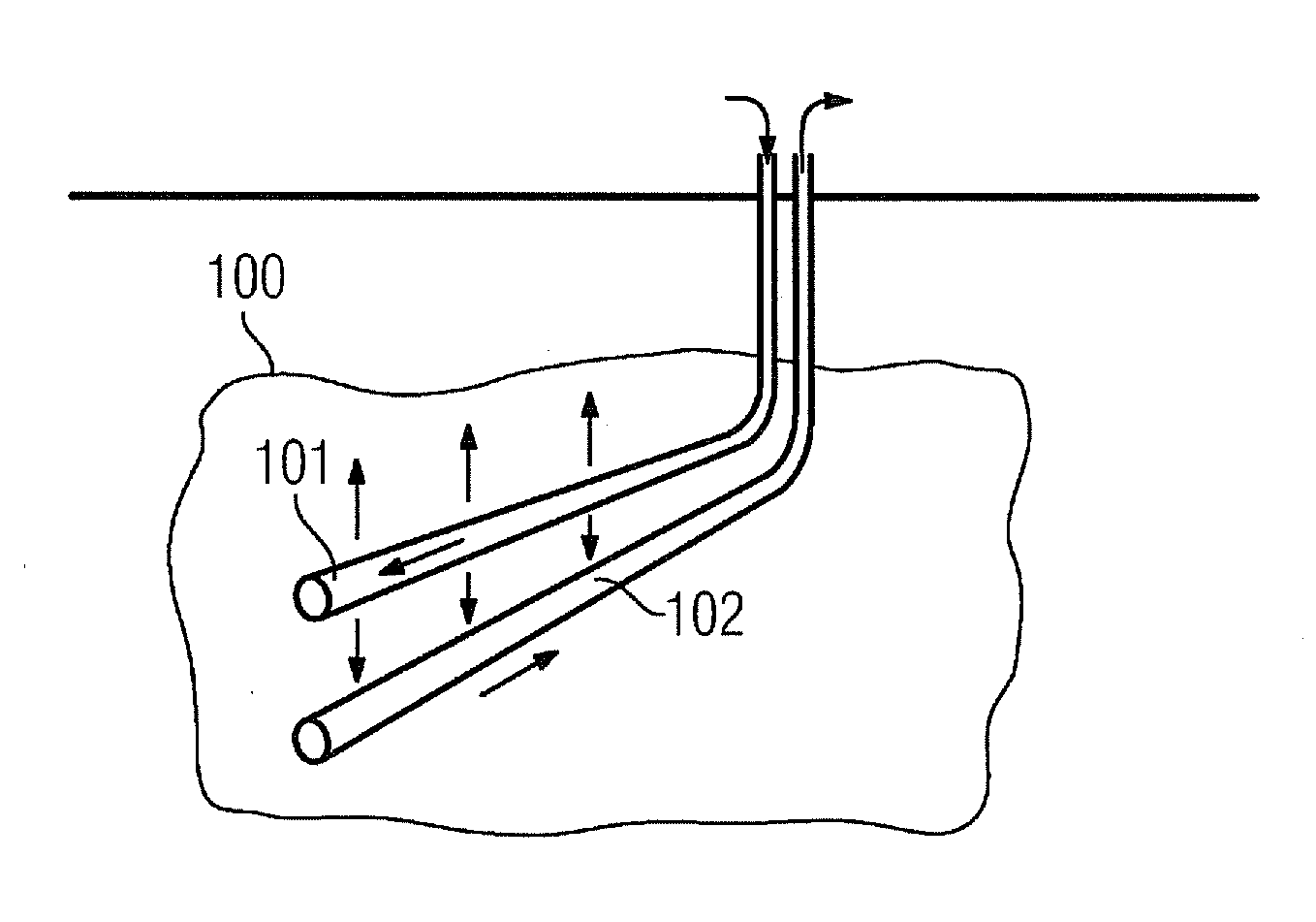

[0032]FIG. 1 shows a diagrammatic illustration of a device for in situ extraction of a substance comprising hydrocarbons from an underground storage site 100 while reducing the viscosity thereof. Such a device can for example be a device for extraction of bitumen from an oil sand deposit. An injection pipeline 101 runs from the earth's surface into the storage site 100. A production pipeline 102 leads out of the storage site 100 to the earth's surface. Devices are conceivable in which a plurality of injection pipelines 101 and a plurality of production pipelines 102 are used to convey the substance comprising hydrocarbons from the underground storage site 100. The storage site 100 can in particular be an oil sand deposit or an oil shale deposit, from which bitumen or other heavy oils can be extracted.

[0033]To be able to extract the substance comprising hydrocarbons from the storage site 100, the viscosity of the substance comprising hydrocarbons present in the storage site 100 must ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com