Physical simulation device and simulation method for coal bed methane production

A technology of physical simulation and simulation method, which is applied to the physical simulation device of coalbed methane production and its simulation field, and can solve the problems such as the inability to guarantee the accuracy of numerical simulation, the inability to try various gas well working systems, and the inability to obtain productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

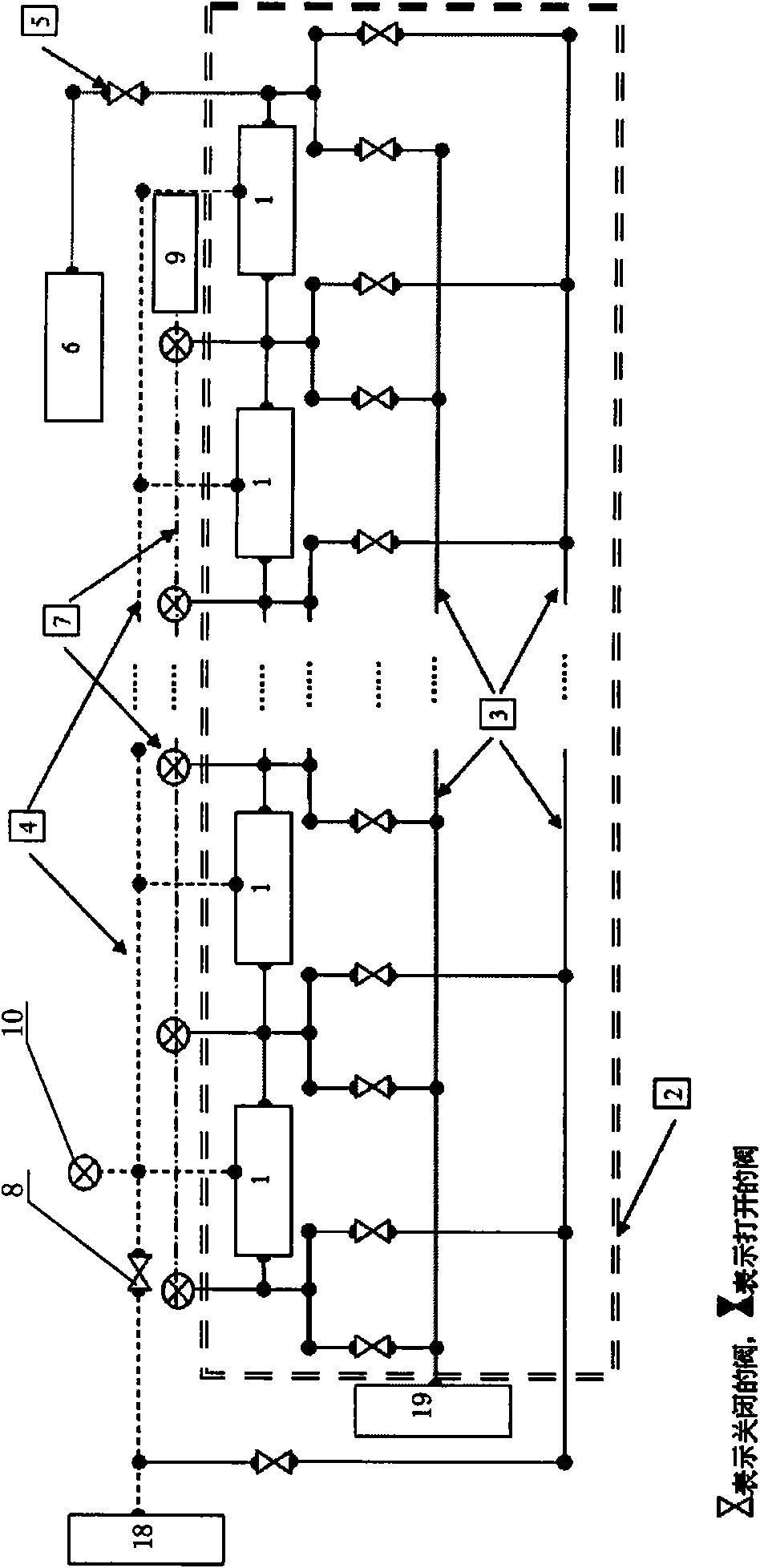

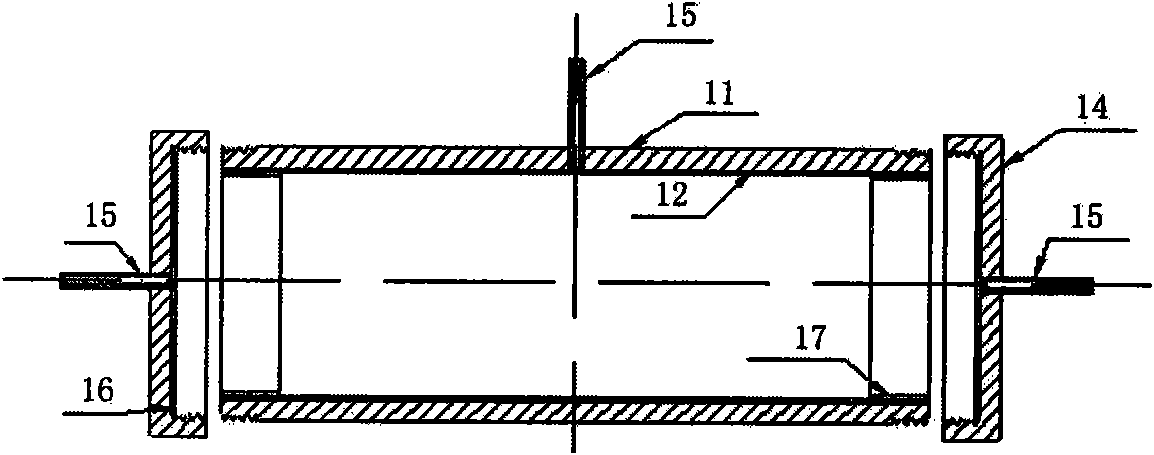

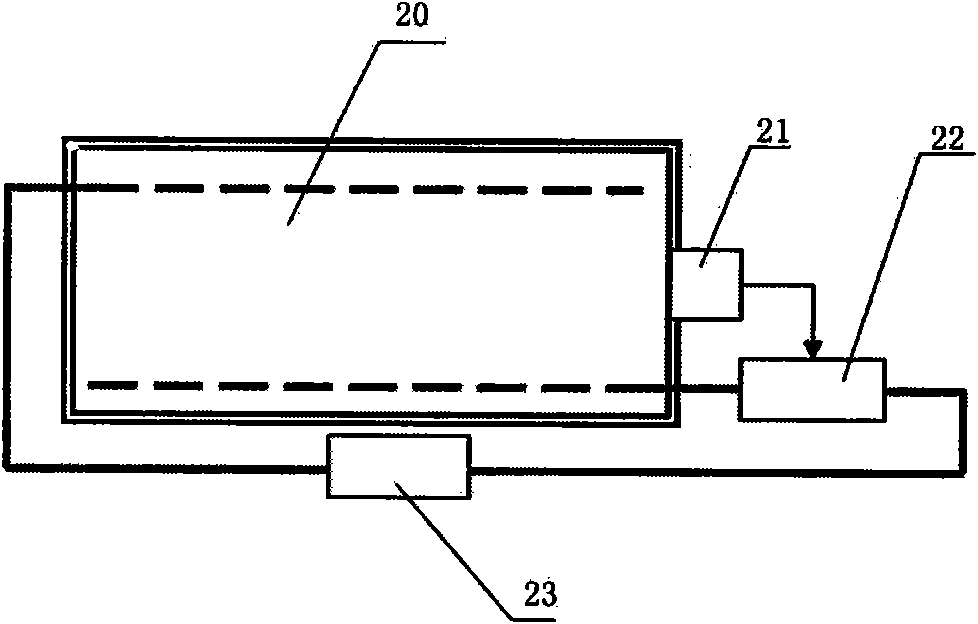

[0037] see figure 1 , a physical simulation device for coalbed methane production, including a number of sample chambers 1, a constant temperature water bath system 2, a water gas metering system 6 and a pressure monitoring system 7, and a high pressure gas cylinder 19 and a high pressure water pump 18 are connected to the water gas configuration production pipeline 3 , the high-pressure water pump 18 is connected to the confining pressure simulation pipeline 4 at the same time, and the confining pressure condition of the gas layer is realized through the high-pressure gas cylinder 19 and the high-pressure water pump 18. The sample chamber 1 can accommodate a coal core with a length of 500 mm and a diameter of 45-50 mm, which can simulate a reservoir The confining pressure is 15Mpa, which can simulate the reservoir pressure of 8Mpa. The sample chamber 1 is connected to each other through the water-gas configuration production pipeline 3 to form a simulation system. The water-ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com