Detection method of PET bottle cap and liquid level

A detection method and bottle cap technology, which are applied in liquid/fluid solid measurement, measurement device, liquid level indicator, etc., can solve the problems of consumer injury, high algorithm complexity, insufficient detection rate, etc., to prevent image jitter, High detection efficiency and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

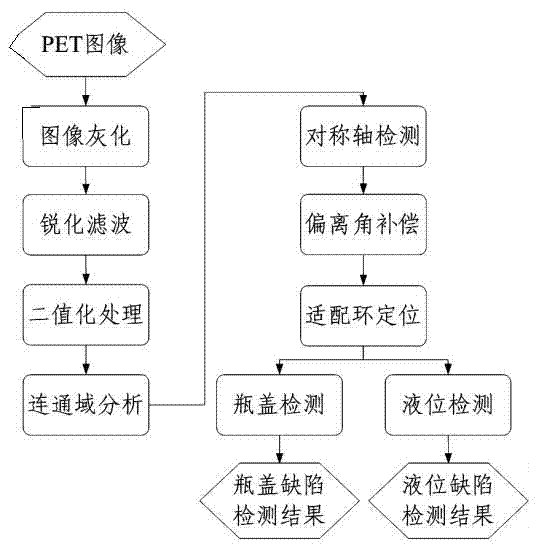

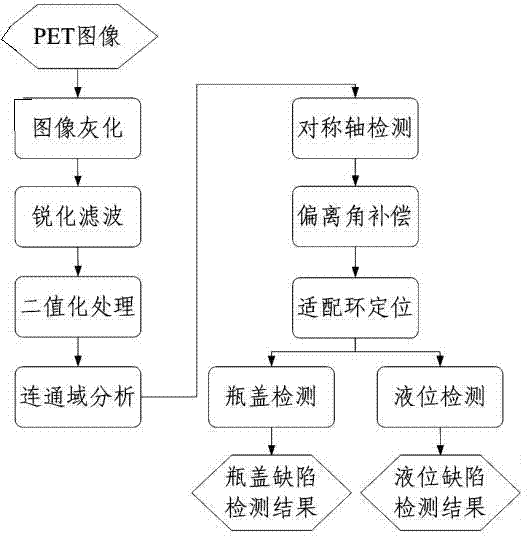

[0014] Combine figure 1 The process flow chart of the present invention is shown to further describe the present invention. The present invention includes the following steps:

[0015] Step (1): Input the captured PET bottle image into the computer, and segment the image into the region of interest.

[0016] Step (2): Perform image preprocessing on the region of interest to complete the segmentation of the PET bottle body region and the background region. The method of image preprocessing is as follows: firstly, the entire image is grayed out, and only the brightness information of the image is retained; secondly, the grayed out single-channel image is filtered to make the edges of the image clear; again, according to the entire image The grayscale histogram determines the threshold of image binarization, and performs binarization processing on it; finally, the connected domain analysis is performed on the binarized image, and the upper left corner belongs to the background area, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com