Constant pulsed light xenon lamp solar cell testing method

A solar cell and testing method technology, applied in the field of solar cell testing, can solve problems such as difficult optical path debugging, increased equipment volume, complex processing of reflective devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

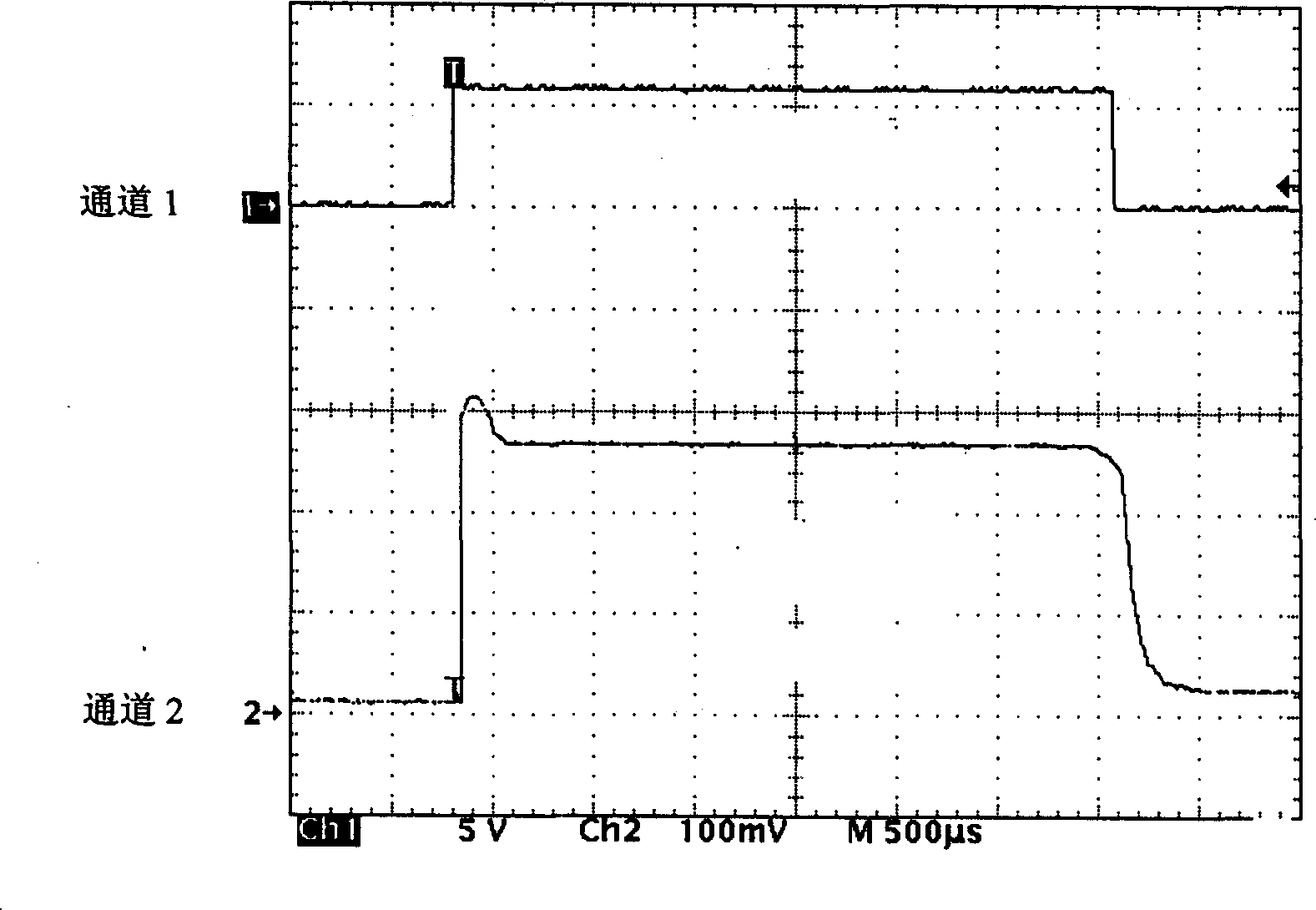

[0017] Example 1: Constant light intensity pulsed xenon lamp single solar cell test

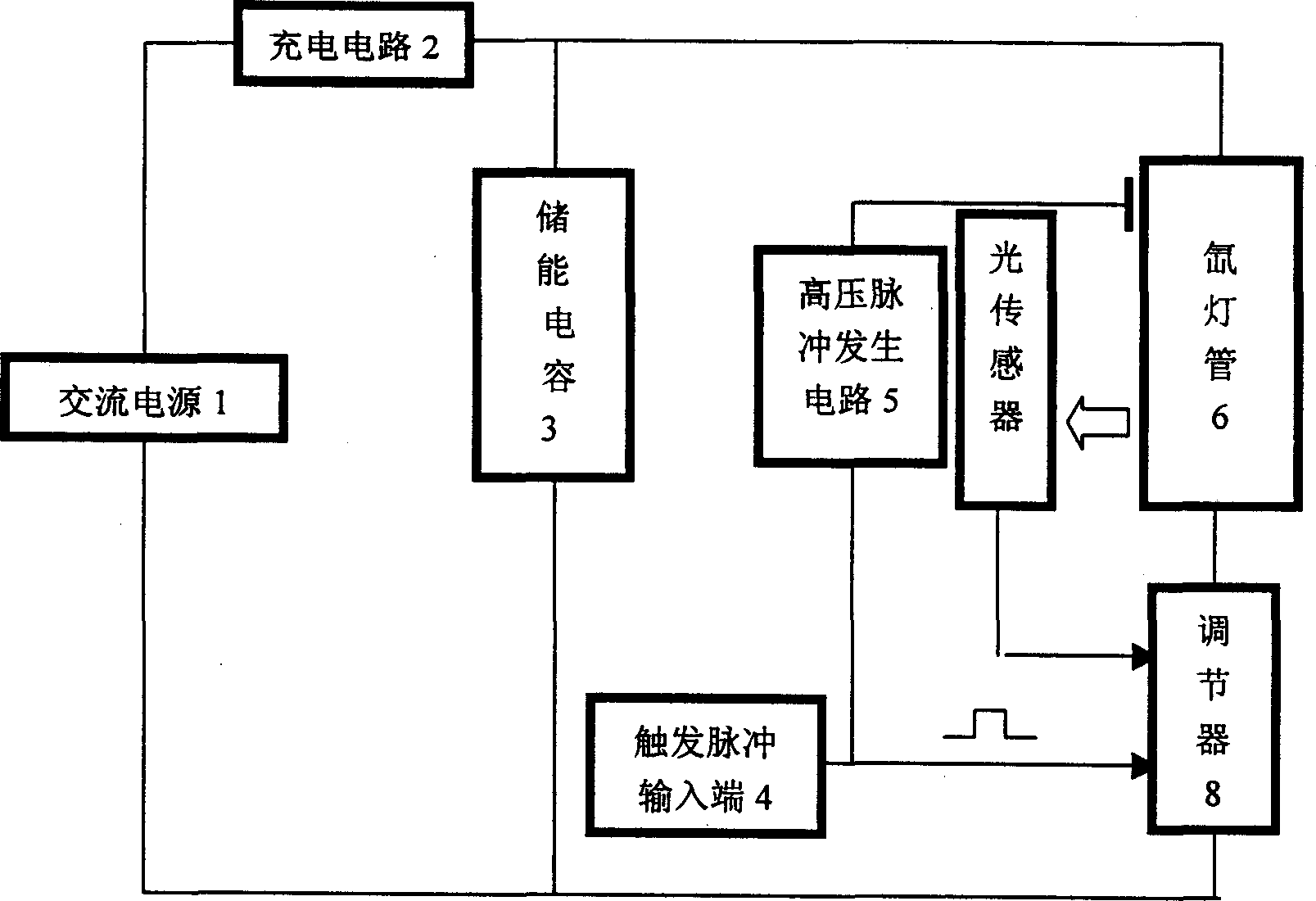

[0018] The core of this embodiment is to propose a new implementation of constant light intensity pulsed xenon lamp, the block diagram is as follows figure 1 shown, including:

[0019] AC power supply 1, charging circuit 2, energy storage capacitor 3, trigger pulse input terminal 4, high voltage pulse generating circuit 5, xenon lamp tube 6, light sensor 7, regulator 8.

[0020] The AC power supply 1 is connected to the energy storage capacitor 3 through the charging circuit 2, and the two ends of the energy storage capacitor 3 are connected to the xenon lamp tube 6 through the regulator 8 connected in series, and the trigger pulse input terminal 4 and the light sensor 7 are respectively connected to the regulator 8, The trigger pulse input terminal 4 is connected to the auxiliary electrode of the xenon lamp tube 6 through the high voltage pulse generating circuit 5 .

[0021] The AC power ...

Embodiment 2

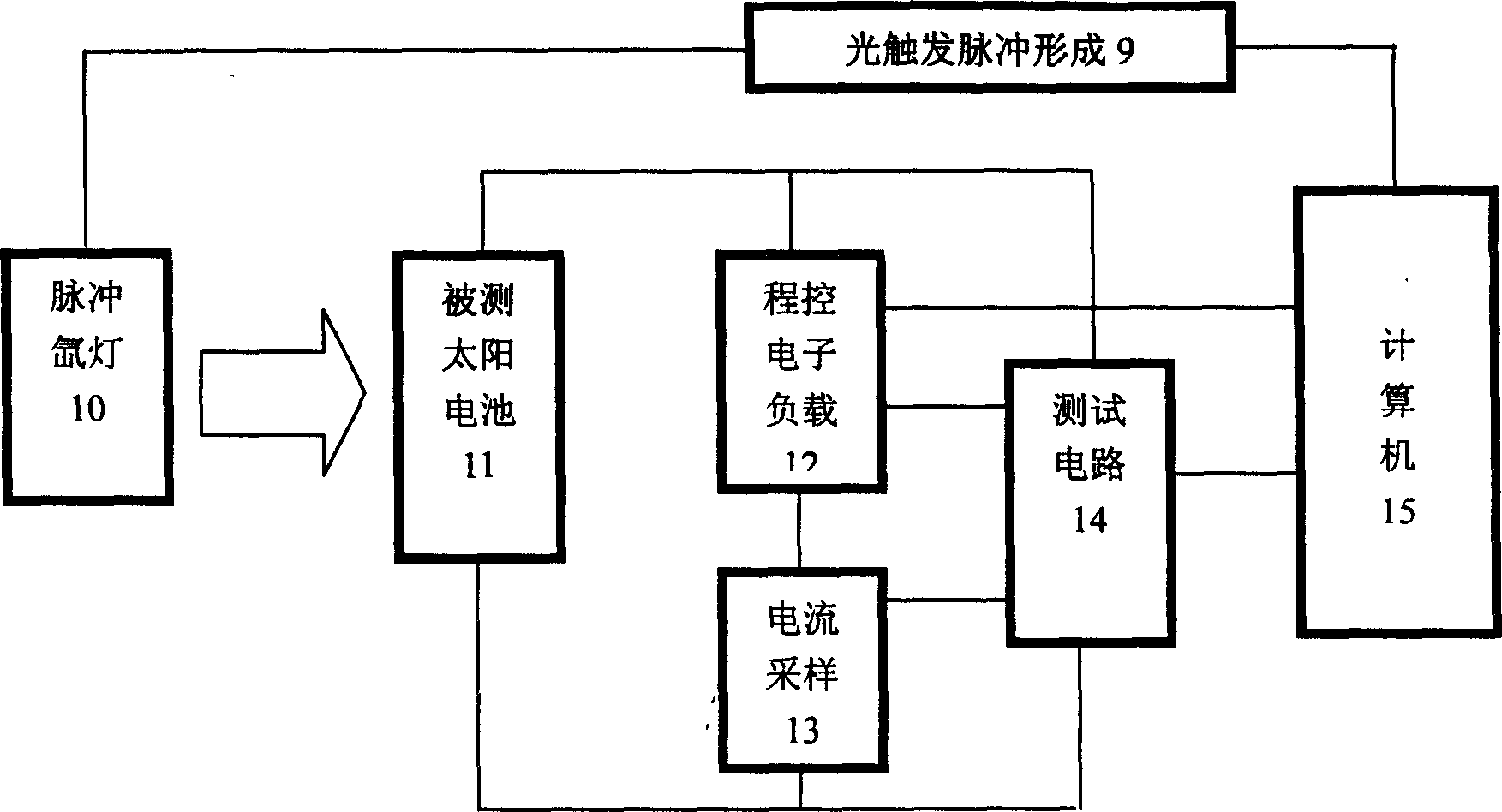

[0026] Example 2: Constant Light Intensity Pulse Xenon Lamp Solar Cell Module Test

[0027] In the solar cell assembly testing device prepared by the present invention, the pulse xenon lamp is about 2 meters away from the test plane of the solar cell assembly to be tested; four reflectors with adjustable angles are arranged in the testing device. By adjusting the angle and light reflection coefficient of the reflector, the light intensity uniformity of the 120CM×60CM test surface can meet the requirements.

[0028] Its structure and principle are as Figure 4 shown. Four reflectors 16 that can adjust the angle are installed in the test device. The light path from the constant light intensity pulse xenon lamp 10 directly to point A is shorter than the light path to point B, and the light intensity at point A is also large, but what hits point B is also the light reflected by point C of the reflector, two beams After the superposition of the light in the normal direction of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com