Method for monitoring oilfield high infiltration strip

A technology for high-permeability strips and oil fields, which is used in surveying, earth-moving drilling, wellbore/well components, etc., to achieve the effect of convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

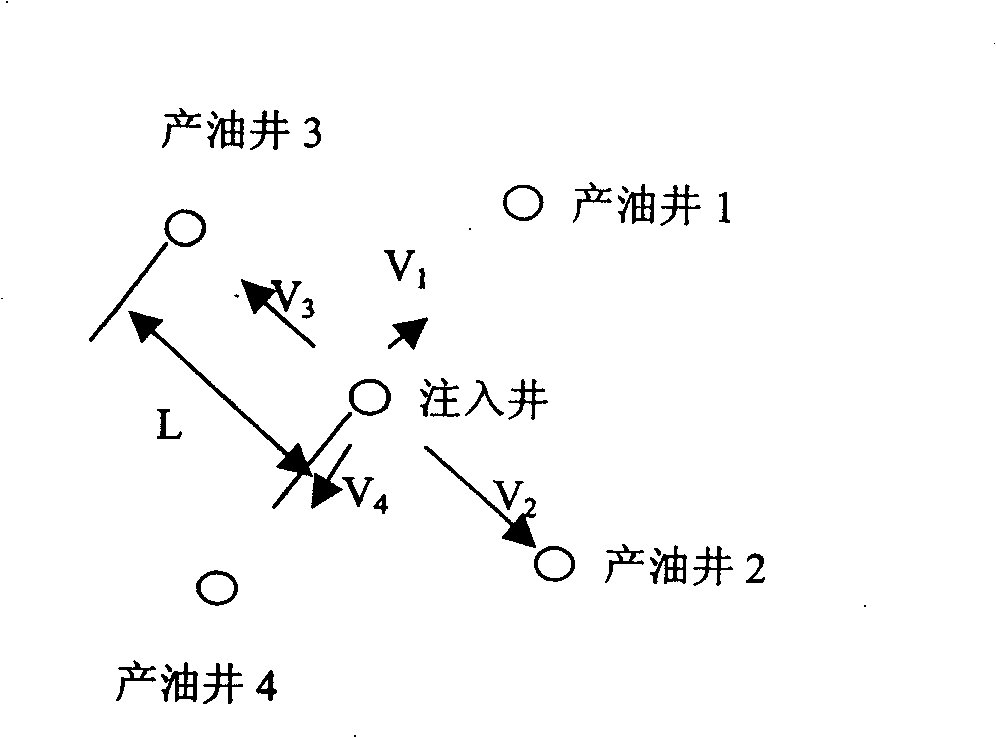

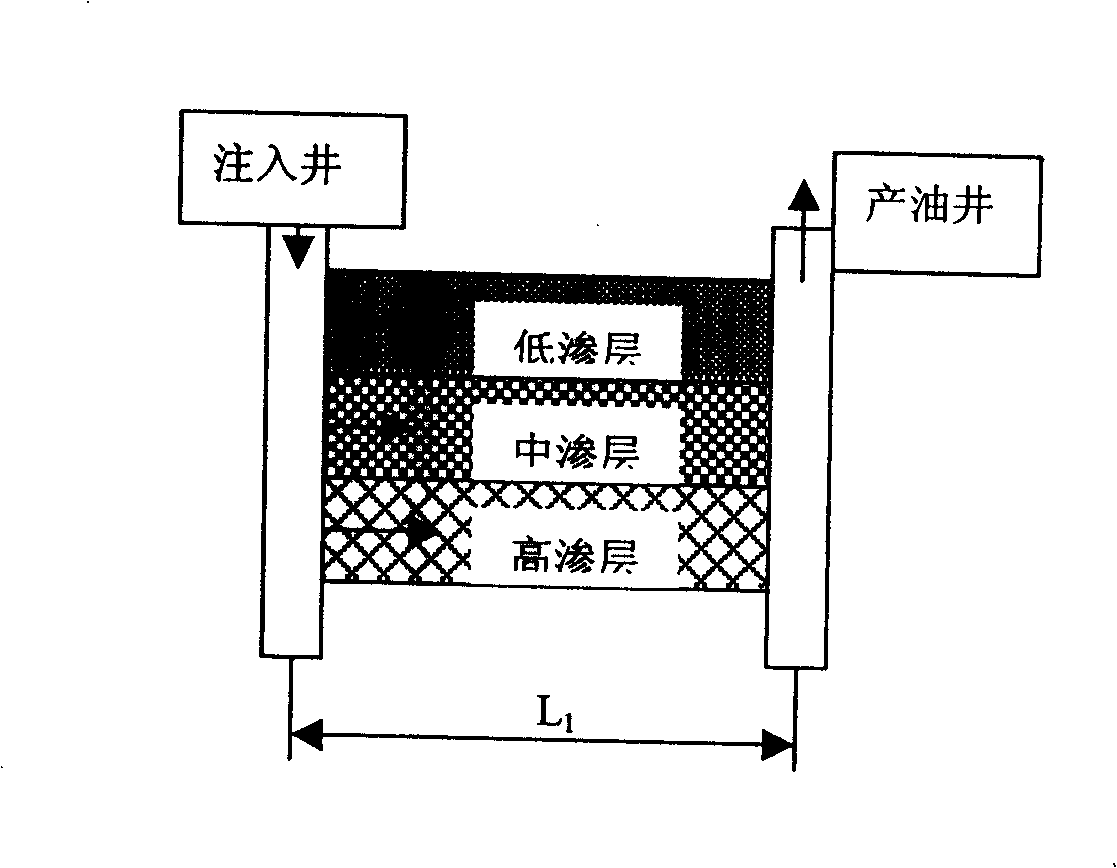

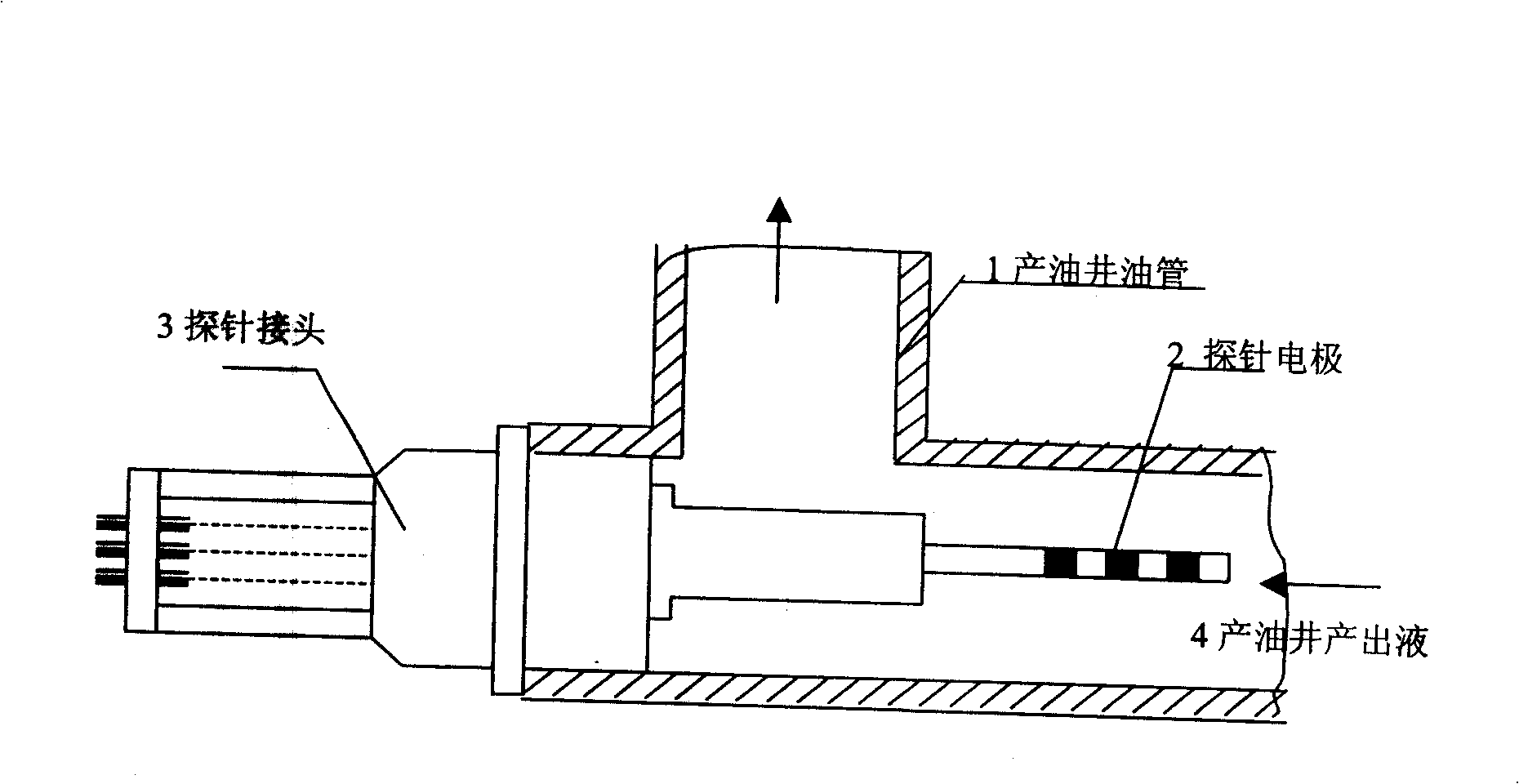

[0021] The present invention applies patent ZL01123944.1 and patent ZL01232851.0 micro-probes for measuring saturation to the oil field site to quickly monitor the heterogeneity and high permeability bands of oil reservoirs. Injecting high-salinity brine into water injection wells, due to the heterogeneity and high-permeability bands in the reservoir, the high-salinity brine flows at different speeds in the reservoir, some directions flow fast, and some directions The flow is slow, and the resistivity change of the output fluid of each oil production well is measured by installing microprobes on the pipelines of multiple oil production wells.

[0022] Since the resistivity is inversely proportional to the salinity of the brine: the higher the salinity, the lower the resistivity, and the change of the salinity of the water in the produced liquid can be measured by the change of the resistivity. When the microprobe measures the sharp drop in the resistivity of the produced fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com