Method for producing liquid milk product containing fruit-vegetable granules

A fruit and vegetable granule and production method technology, which is applied in the direction of milk preparations, dairy products, food preparation, etc., can solve the problems of affecting the taste, expensive equipment, and increasing the complexity of the production process, so as to reduce the broken rate and avoid mechanical damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

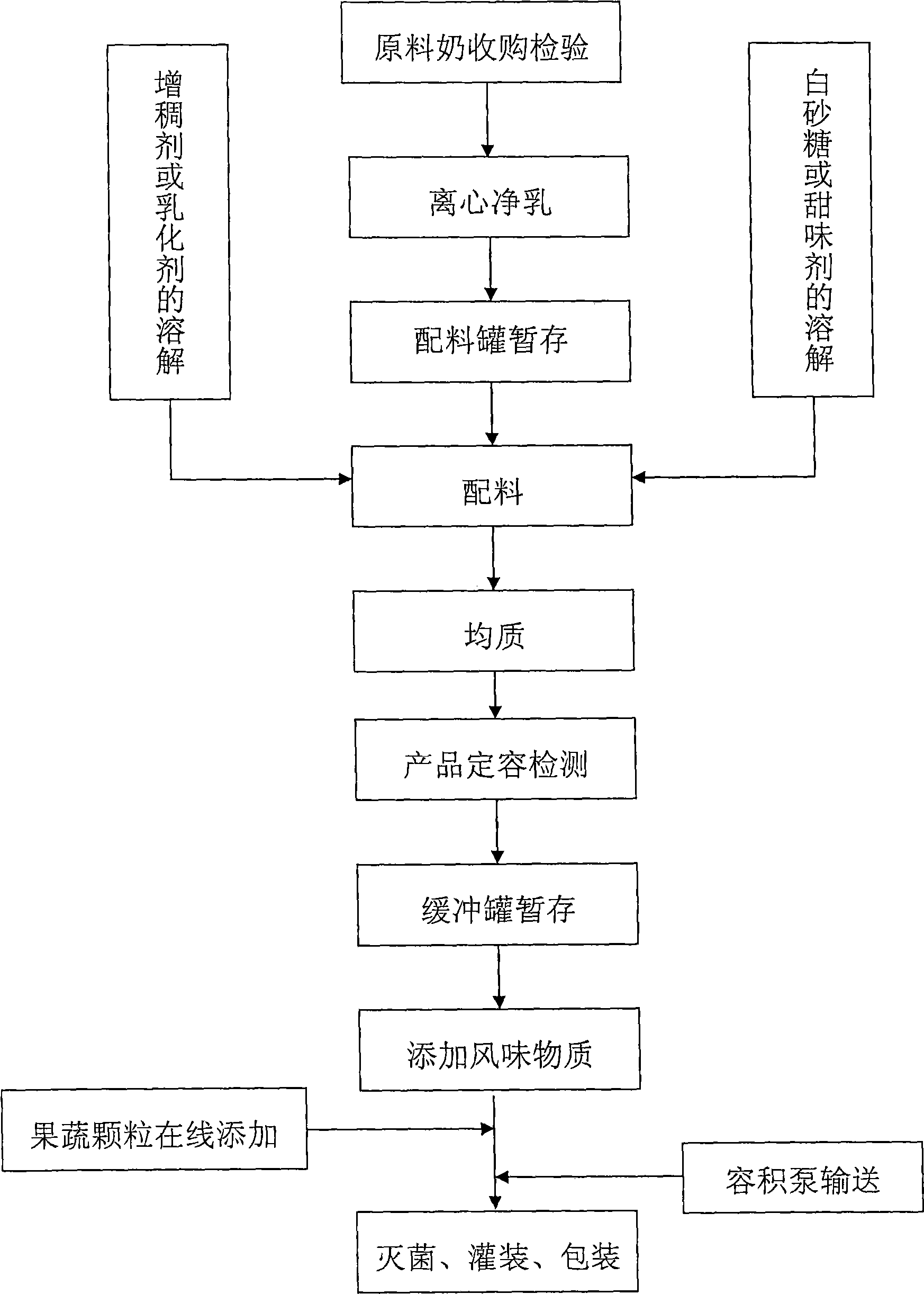

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, the milk beverage containing coconut fruit grain, celery grain and production method thereof

[0047] Formula (based on one ton of product):

[0048] Milk 350kg

[0049] White sugar 50kg

[0050] Gellan Gum 1.5kg

[0051] Propylene glycol alginate 1 kg

[0052] Sodium carboxymethyl cellulose 2 kg

[0053] Monoglycerides 1 kg

[0054] Lactic acid 2 kg

[0055] citric acid 2 kg

[0056] Nata de coco 25kg

[0057] Celery granules 25kg

[0058] Flavor 1.5kg

[0059] Balance water.

[0060] Raw material standard:

[0061] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%.

[0062] White granulated sugar: in line with the national first-class standard.

[0063] The raw materials of coconut fruit granules are pre-processed fruit and vegetable products: the pulp content is ≥65.0%; the fruit particle size is 3mm; the pulp is fresh and has the normal aroma of coconut fruit; pH: 3.50-4.3; sugar content: 23BX.

[0064] The raw material of cel...

Embodiment 2

[0072] Embodiment 2, milk beverage containing yellow peach fruit grains and radish grains and production method thereof

[0073] Formula (based on one ton of product):

[0074] Milk 500kg

[0075] White sugar 55kg

[0076] Sodium carboxymethyl cellulose 3 kg

[0077] Gellan gum 1.2 kg

[0078] Propylene glycol alginate 1 kg

[0079] Monoglyceride Tartrate 1 kg

[0080] Lactic acid 2.2 kg

[0081] citric acid 2 kg

[0082] Yellow peach diced 30kg

[0083] Radish granules 30kg

[0084] Flavor 1.5kg

[0085] Balance water.

[0086] Raw material standard:

[0087] Milk: protein ≥ 2.95%; fat ≥ 3.0%; non-fat milk solids ≥ 8.5%.

[0088] White granulated sugar: in line with the national first-class standard.

[0089] Yellow peach fruit granules are made of pre-processed fruit and vegetable products: pulp content ≥ 65.0%; fruit particle size: 5mm; fresh pulp with normal aroma of yellow peach; pH: 3.00-3.60; sugar content: 35-40BX.

[0090] The raw materials of radish gra...

Embodiment 3

[0098] Embodiment 3, the production method of the lactic acid bacteria beverage containing pineapple fruit grain, cucumber grain

[0099] Formula (based on one ton of product):

[0100] Yogurt 350kg

[0101] White sugar 55kg

[0102] Sodium carboxymethyl cellulose 3 kg

[0103] Pectin 1.5 kg

[0104] Gellan Gum 1.5kg

[0105] Propylene glycol alginate 1.2 kg

[0106] Monoglyceride tartrate 0.1 kg

[0107] Lactic acid 0.5 kg

[0108] citric acid 1 kg

[0109] Pineapple diced 40kg

[0110] Cucumber Granules 40kg

[0111] Flavor 1.5kg

[0112] Balance water.

[0113] Raw material standard:

[0114] Milk: protein ≥ 2.95%; fat ≥ 3.0%; non-fat milk solids ≥ 8.5%.

[0115] White granulated sugar: in line with the national first-class standard.

[0116] The raw materials of pineapple granules are pre-processed fruit and vegetable products: pulp content ≥ 60.0%; fruit particle size: 3-8mm; fresh pulp with normal pineapple aroma; pH: 3.70-4.30; sugar content: 35-40BX.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com