Underground coal gasifying furnace and underground coal gasifying method

An underground gasification and gasification furnace technology, which is applied in coal gasification, underground mining, earth drilling and mining, etc., can solve the problems of slow penetration speed and unstable structure in the gasification production stage, and achieve the effect of eliminating slow penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

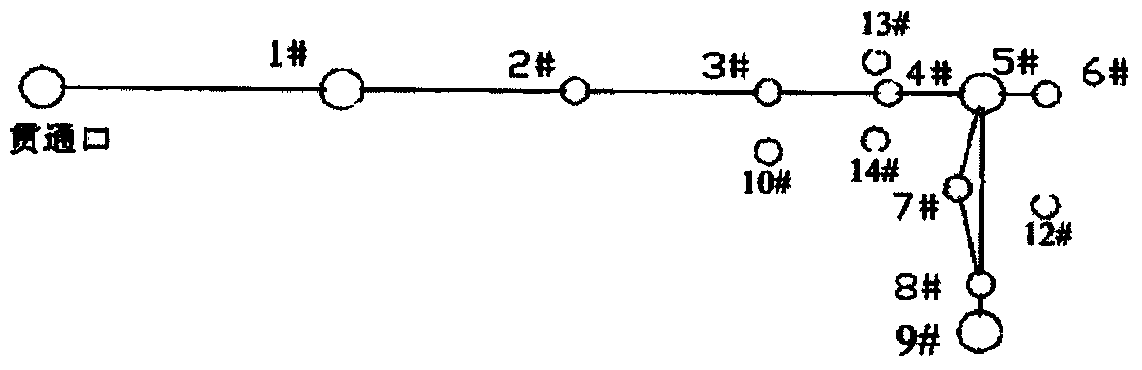

[0050] The underground coal gasification furnace and the underground coal gasification method of the present invention are illustrated by taking a horizontal 10m thick bituminous coal seam with a buried depth of 500m somewhere as an example.

[0051] First, see Figure 4 Drill a first vertical drilling well 1 to the middle and lower part of the coal seam in the selected area where the underground gasifier is to be built, drill the first horizontal directional drilling well a to the first vertical drilling well 1 against the development direction of coal seam fissures, and drill the first horizontal directional drilling well a The length of the horizontal borehole in the middle and lower part of the coal seam is 250m, about 5m on both sides of the first horizontal directional drilling a, and a second vertical drilling 2-7 is drilled at an interval of 25m to the middle and lower part of the coal seam, and the second vertical drilling 2 ~7 are alternately distributed on both side...

Embodiment 2

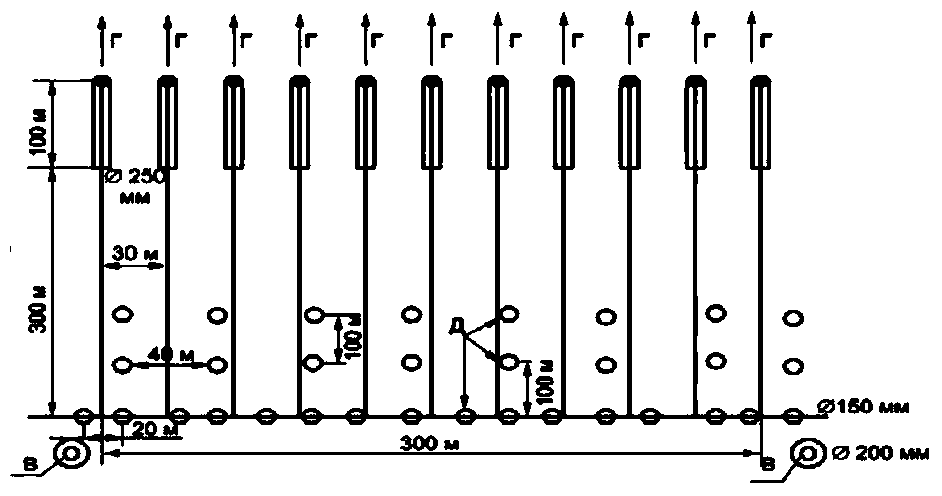

[0058] The underground coal gasification furnace and the underground coal gasification method of the present invention are illustrated by taking a horizontal 8m thick lignite coal seam with a buried depth of 300m as an example.

[0059] First, in the coal seam area selected for underground gasification, the development direction of coal seam fractures is determined according to the geological information, such as Figure 5 The direction indicated by the arrow. Select a point to drill the first vertical drilling 1 to the middle and lower part of the coal seam, and drill the second vertical drilling to the middle and lower part of the coal seam at intervals of about 35m along the development direction of the coal seam fissures, numbered 2, 3, 4, 5, 6, and then in the opposite direction. Drill the first horizontal directional drilling well a in the direction of the first vertical drilling 1 at a point in the direction of the coal seam fissure, and the drilling length in the horiz...

Embodiment 3

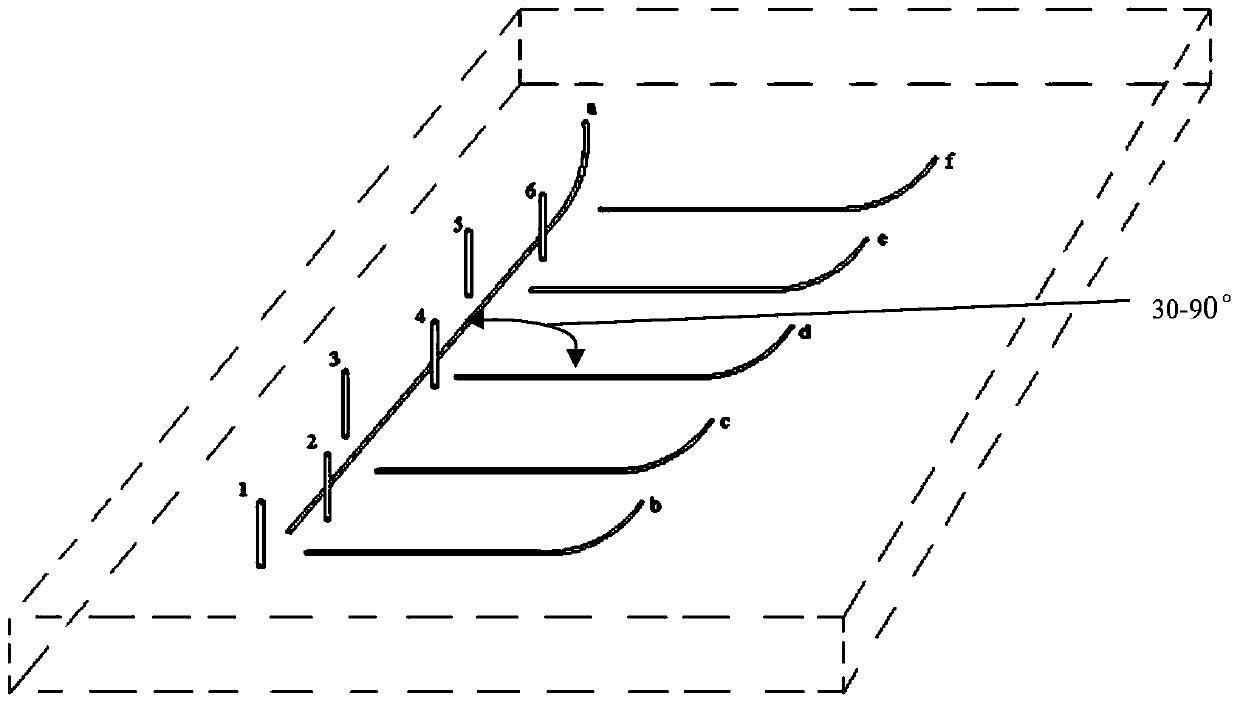

[0064] The underground coal gasification furnace and the underground coal gasification method of the present invention are illustrated by taking a 12m thick subbituminous coal seam with a buried depth of 600m somewhere as an example.

[0065] First, see Figure 6 Drill a first vertical drilling well 1 to the middle and lower part of the coal seam in the selected area where the underground gasifier is to be built, drill the first horizontal directional drilling well a to the first vertical drilling well 1 against the development direction of coal seam fissures, and drill the first horizontal directional drilling well a The length of the horizontal drilling in the middle and lower part of the coal seam is 250m, and a second vertical drilling 2, 3 is drilled at a distance of about 100m at 5-15m on one side of the first horizontal directional drilling a to the middle and lower part of the coal seam, distributed in the second The same side of a horizontal directional drilling well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com