Reception, processing, handling and distribution of hydrocarbons and other fluids

a technology for hydrocarbons and other fluids, which is applied in the direction of liquid handling, container discharging methods, packaged goods types, etc., can solve the problems of large capital investment, large capital and operating costs, and large capital investment, and achieves the reduction of the rate, the effect of reducing the offload time of carriers, and substantial savings in capital and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

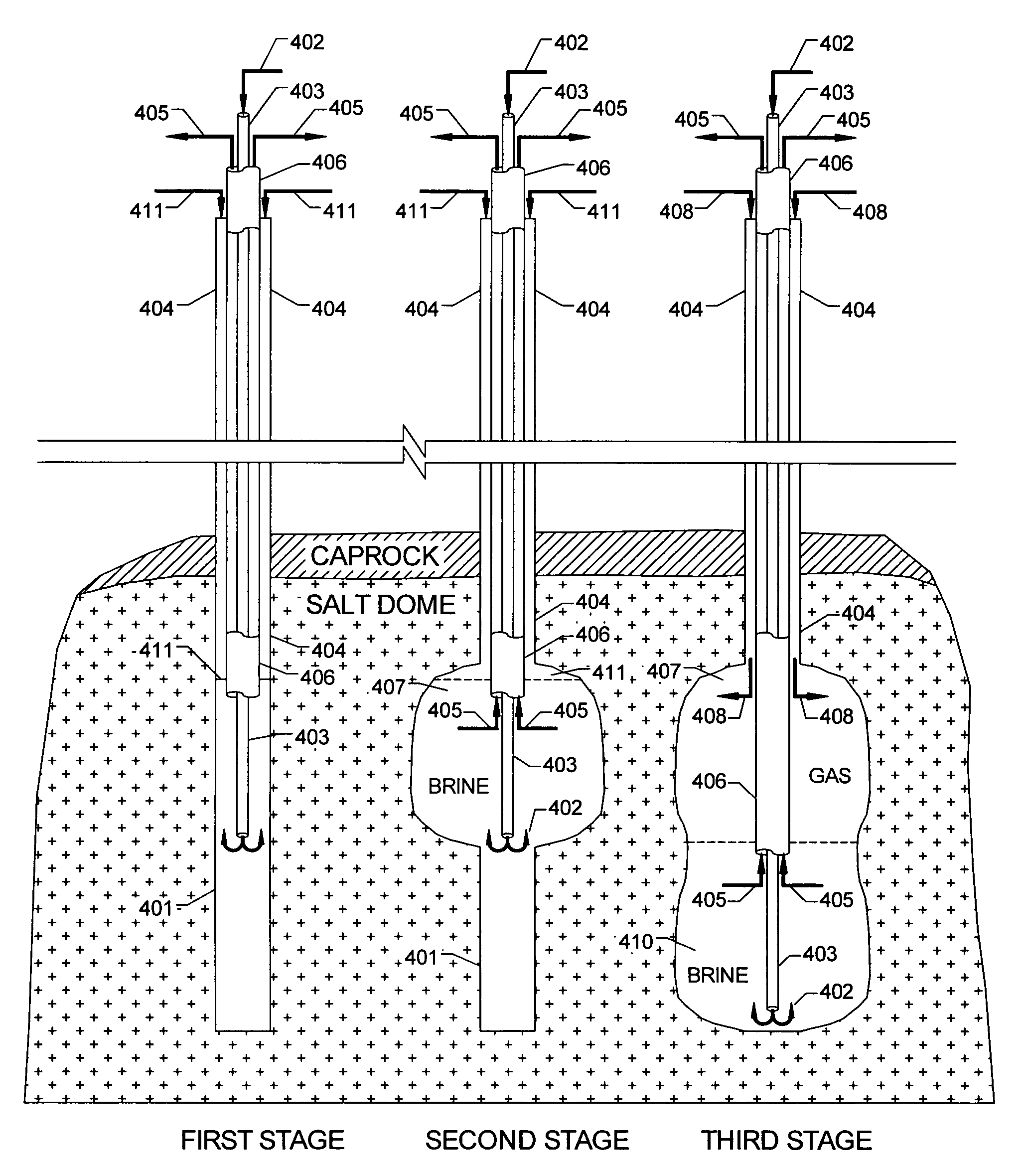

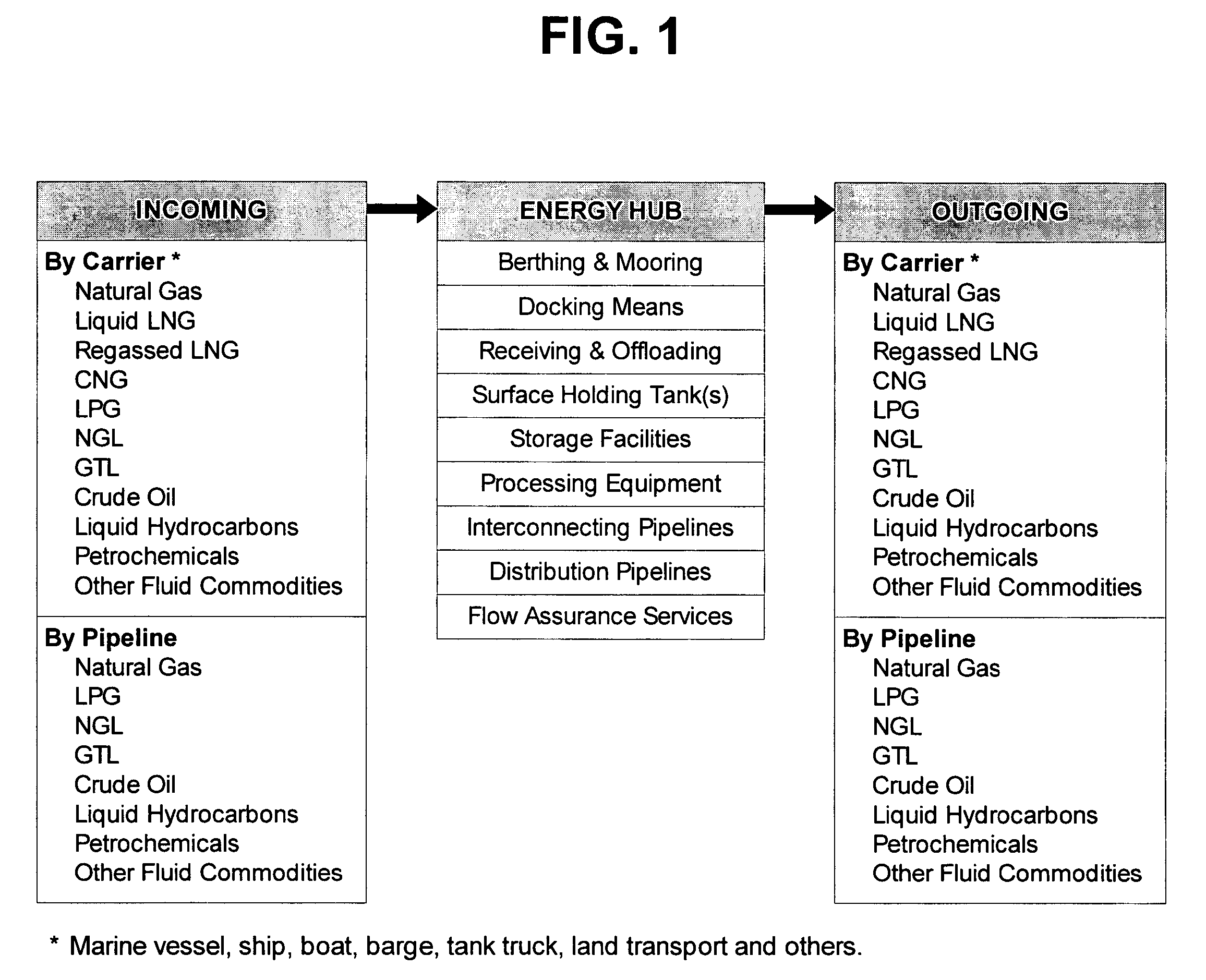

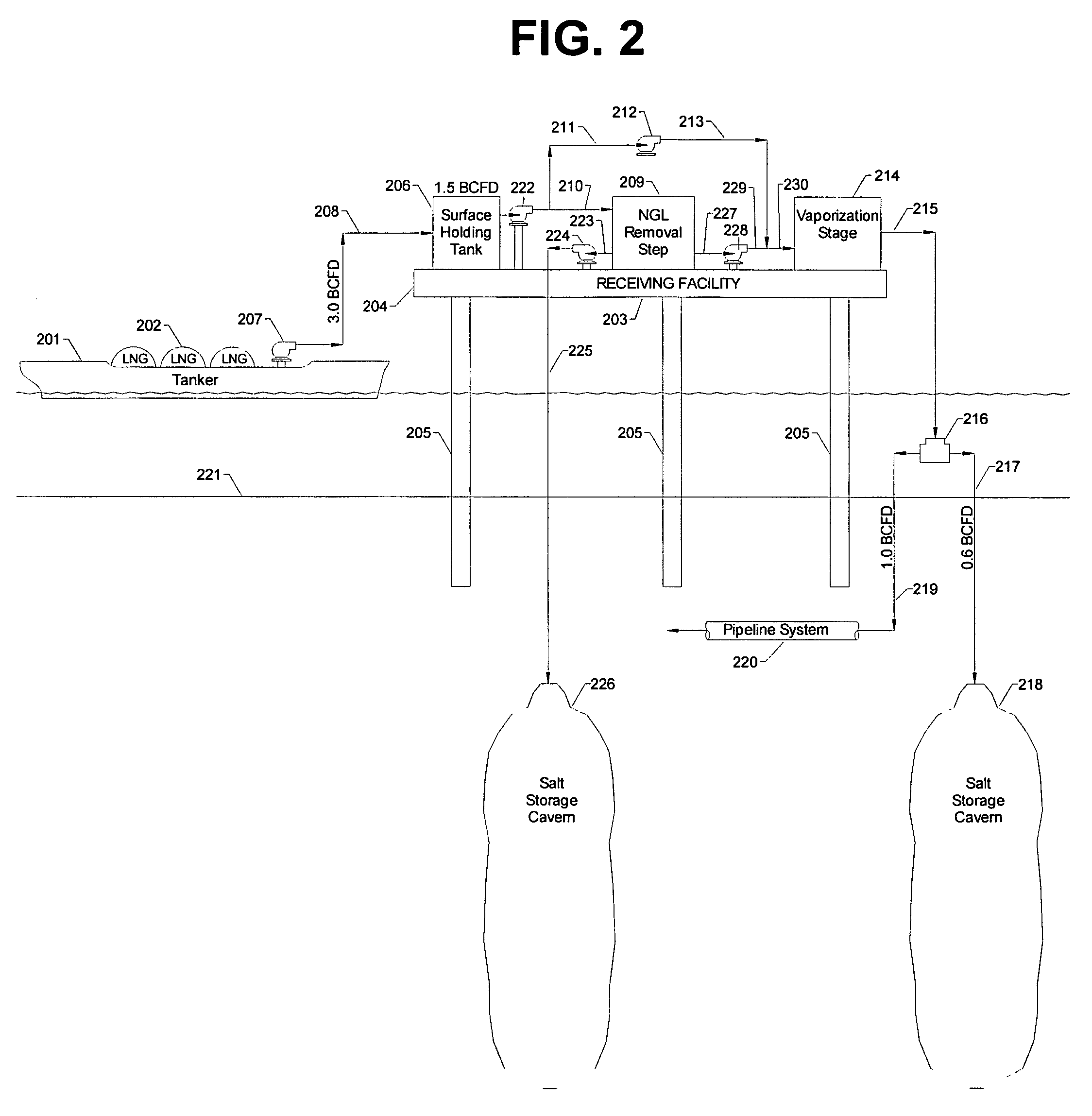

[0014]Referring to FIG. 1, the variety of fluids that the energy hub facility of this invention is able to receive, process, store and / or deliver is shown on the left side of the block labeled “Energy Hub” under the heading “Incoming”. As shown on FIG. 1, these fluids may arrive at the energy hub by carrier ships, boats, barges, tanker trucks, land transport and / or pipelines, and include natural gas, liquefied natural gas (LNG), regassed LNG, compressed natural gas (CNG), liquefied petroleum gas (LPG), natural gas liquids (NGL), gas-to-liquid products (GTL), crude oil (with or without mixed gas), liquid hydrocarbons, petrochemicals, and other fluid commodities, such as mineral and vegetable oils, NaOH, NaCl clarifiers, ethylenebenzene, benzene, raffinate and other liquid and gaseous chemicals. The fluids are handled and processed at the energy hub, which is equipped with means for berthing, mooring and docking ships, boats, barges, trucks and / or land transport, receiving and offload...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com