Method and device for preparing oxygen-free protective gas by removing oxygen and impurities from air

A technology for protecting gas and air, applied in the direction of inert gas generation, etc., can solve problems such as inactive chemical properties, dirty odor, moldy and rotten items, etc., and achieve the effect of simple and reliable product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

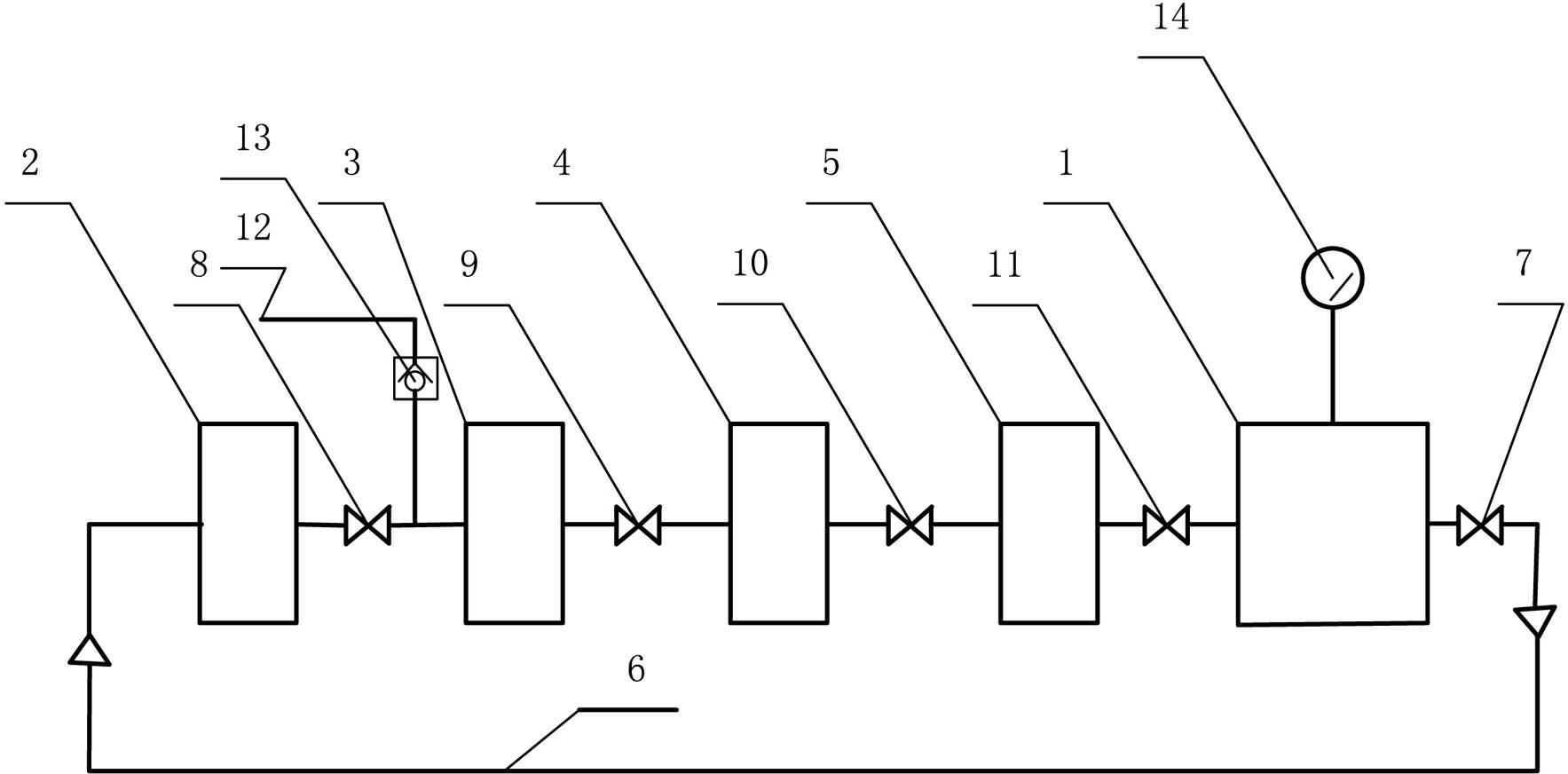

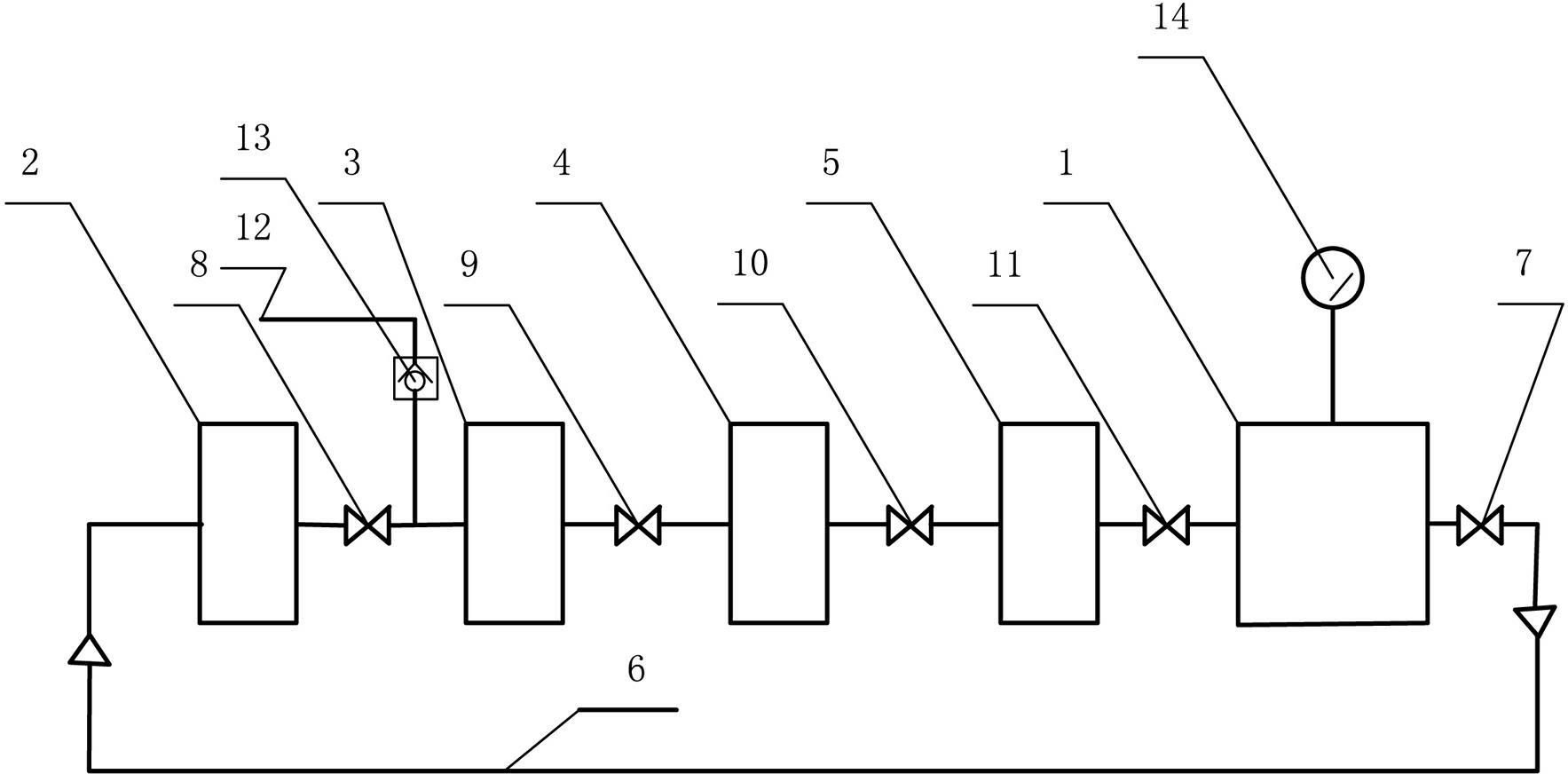

[0027] Example 1 as figure 1 shown. This embodiment is a method for preparing gas by removing oxygen and impurities from air, and a device for realizing the method. The device includes a sealed container 1 filled with air, a roasting chamber 3, a cooling water washing pool 4, and a dust removal chamber 5. 6 Connect the sealed container 1, the roasting chamber 3, the cooling water washing pool 4, and the dust removal chamber 5; The air pump 2 is set on the pipeline 6 between the chambers 3; in order to control the flowing gas, the air pump 2 is respectively set on the pipeline between the airtight container 1, the air pump 2, the roasting chamber 3, the cooling water washing pool 4, and the dust removal chamber 5 There is a fifth valve 7 , a first valve 8 , a second valve 9 , a third valve 10 and a fourth valve 11 . In order to ensure that the air pressure in the sealed container 1 is maintained at a standard atmospheric pressure, the pressure balance pipeline 12 of air is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com