Atomization and polymerization method and device of polyoxamide

A polyoxamide, atomization polymerization technology, applied in chemical/physical/physicochemical nozzle reactors, inert gas generation, etc., can solve the problem that polyoxamide is not suitable for industrial mass production methods, and achieve guaranteed viscosity and high The effect of molecular weight, mild conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

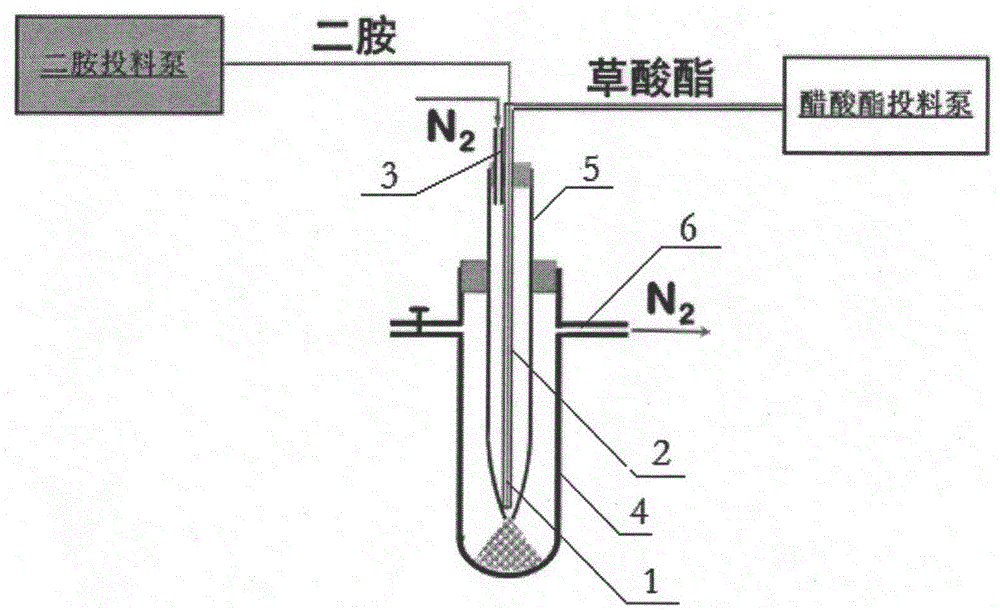

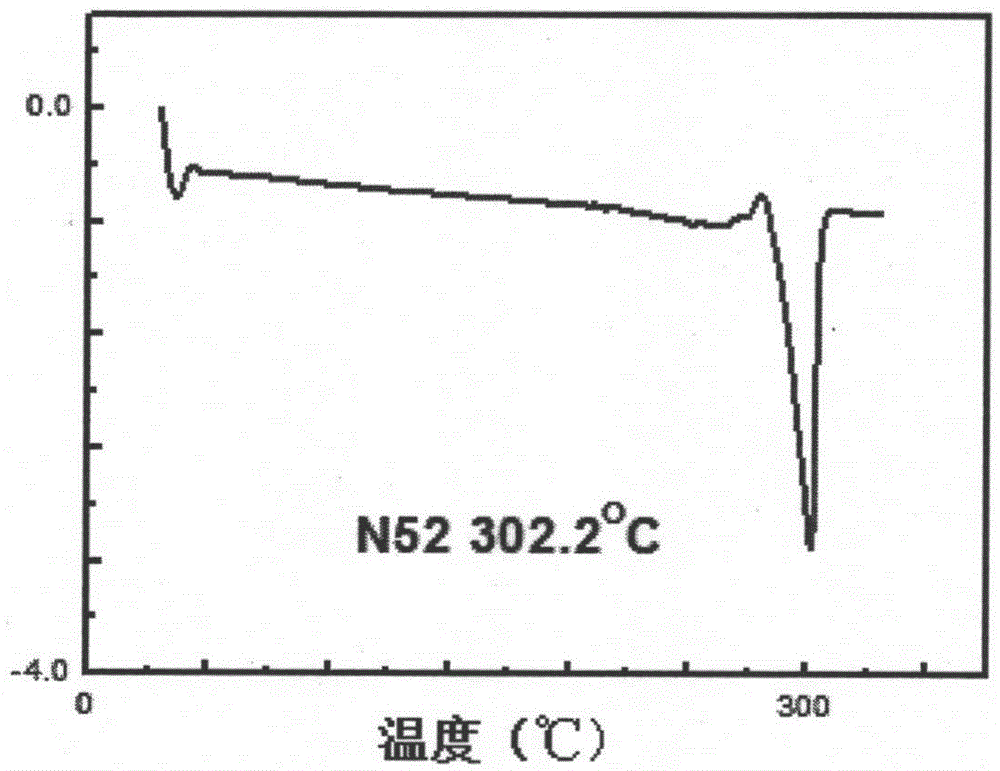

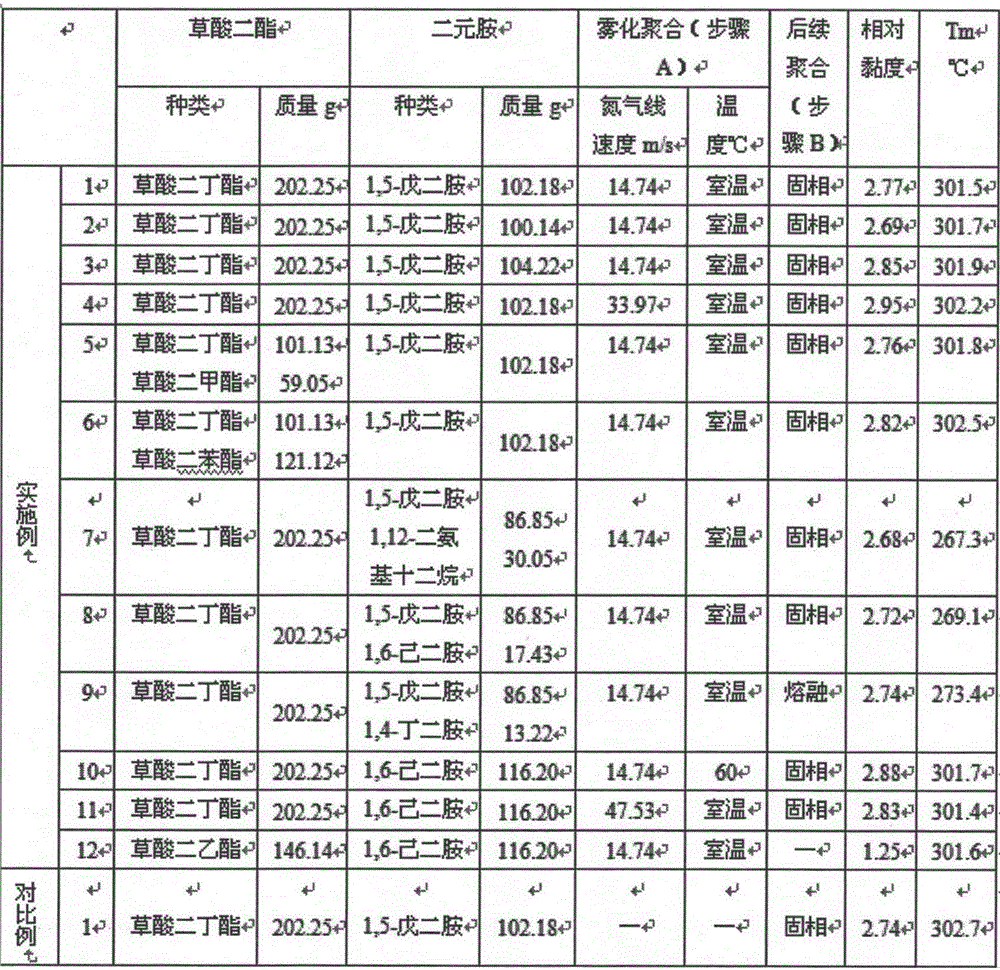

Embodiment 1

[0037] A kind of atomization polymerization method of polyoxamide, concrete steps are: adopt above-mentioned atomization polymerization device, at room temperature, with 202.25g dibutyl oxalate (1mol), 102.18g1, 5-pentanediamine (1mol) respectively Pumped into the outer tube 2 and the inner tube 1 of the liquid sampling tube of the nozzle 5 by the oxalate feeding pump and the diamine feeding pump, the nitrogen flow enters the nozzle 5 from the gas inlet 3, and at room temperature, dibutyl oxalate and 1,5-pentanediamine is sprayed into container 4 through nozzle 5 under the effect of this nitrogen flow (the nitrogen flow velocity at nozzle exit is 14.74m / s), carries out atomization, mixing and polymerization 25min in this nitrogen flow, Obtain a polyoxamide prepolymer; treat the aforementioned prepolymer at a constant temperature of 150°C for 3 hours under the protection of nitrogen, then reduce the pressure to a pressure of less than 200Pa, raise the temperature to 250°C at a h...

Embodiment 2

[0039] A kind of atomization polymerization method of polyoxamide, concrete steps are: adopt above-mentioned atomization polymerization device, at room temperature, with 202.25g dibutyl oxalate (1mol), 100.14g1, 5-pentanediamine (0.98mol) The oxalate feeding pump and the diamine feeding pump are respectively pumped into the outer pipe 2 and the inner pipe 1 of the liquid sampling tube of the nozzle 5, and the nitrogen flow enters the nozzle 5 from the gas inlet 3. At room temperature, dibutyl oxalate and 1,5-pentanediamine are sprayed into container 4 through nozzle 5 under the effect of the nitrogen flow (the nitrogen flow velocity at the nozzle outlet is 14.74m / s), and atomization, mixing and polymerization are carried out in the nitrogen flow for 25min , to obtain a polyamide prepolymer; the aforementioned prepolymer was treated at a constant temperature of 150°C for 3 hours under the protection of nitrogen, and then decompressed to a pressure of less than 200Pa, and the tem...

Embodiment 3

[0041] A kind of atomization polymerization method of polyoxamide, concrete steps are: adopt above-mentioned atomization polymerization device, at room temperature, with 202.25g dibutyl oxalate (1mol), 104.22g1, 5-pentanediamine (1.02mol) The oxalate feeding pump and the diamine feeding pump are respectively pumped into the outer pipe 2 and the inner pipe 1 of the liquid sampling tube of the nozzle 5, and the nitrogen flow enters the nozzle 5 from the gas inlet 3. At room temperature, dibutyl oxalate and 1,5-pentanediamine are sprayed into container 4 through nozzle 5 under the effect of the nitrogen flow (the nitrogen flow velocity at the nozzle outlet is 14.74m / s), and atomization, mixing and polymerization are carried out in the nitrogen flow for 25min , to obtain a polyamide prepolymer; the aforementioned prepolymer was treated at a constant temperature of 150°C for 3h under the protection of nitrogen, then decompressed to a pressure of less than 200Pa, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com