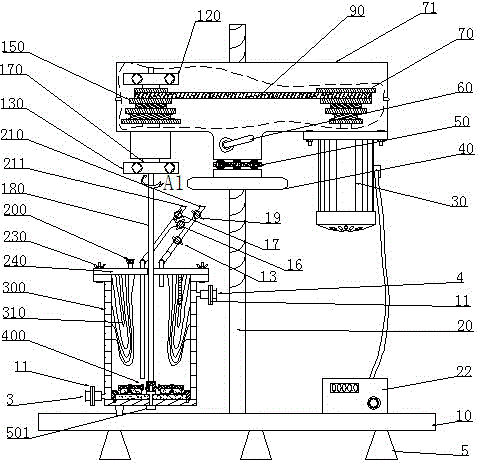

High-shear-force grinding reactor

A high-shear, reactor technology, applied in chemical/physical/physical-chemical stationary reactors, applications, inert gas generation, etc., can solve the problems of difficult to control the gap between dynamic and static abrasives, energy loss, etc., and achieve convenient maintenance. , prolong the service life, not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 (no inert gas protection required, speed ratio = 2, frequency converter is 50Hz, speed = 3000×2 revolutions / min)

[0075] Ultrafine nano-calcium carbonate has a wide range of uses, and its preparation raw materials often use milk of lime and carbon dioxide. The present invention omits the step of preparing milk of lime, and directly prepares it with calcium hydroxide.

[0076] raw material

[0077] Calcium hydroxide (slaked lime, ≥99%) 149.68g

[0078] Carbon dioxide (steel cylinder, 99.8%) 88.2g

[0079] Distilled water 1133.4g

[0080] The equipment parameters used are shown in Table 1 and 2.

[0081] Table 1 Parameters of reaction vessel

[0082] project inner diameter / cm Section / cm 2 Total height H / cm Effective h / cm Volume / L parameter 12 113.1 20 14.00 1.58

[0083] Table 2 Transmission mechanism parameters

[0084] project Motor (r / min) speed ratio Moving shaft (r / min) Movable grinding tool (...

Embodiment 2

[0097] Example 2 (Protected by inert gas, no cooling, speed ratio=4, frequency converter is 50Hz, speed=3000×4rpm)

[0098] nanometer ferric oxide (Fe 3 o 4 ) is a new type of high-function fine inorganic product, and its preparation raw materials are divalent and ferric salts and soluble hydroxides. The present invention adopts equimolar ferrous sulfate, ferric sulfate and sodium hydroxide to react, in order to ensure that the ferrous iron is not oxidized by oxygen in the air during the reaction process, it is prepared under the protection of nitrogen.

[0099] raw material

[0100] Ferrous sulfate heptahydrate (analytically pure, ≥99%) 21.06g

[0101] Ferric sulfate (analytically pure, 99.8%) 67.01g

[0102] Sodium hydroxide (analytically pure, 96%) 27.16g

[0103] Polyvinyl alcohol (PEG4000) solution (analytical grade, 4%) 41.3g

[0104] Distilled water 939.56g

[0105] The equipment parameters used are the same as in Example 1, and the transmission mechanism param...

Embodiment 3

[0126] Example 3 (Change to large reactor, the amount of reactant increases, and all the other conditions are the same as in Example 1)

[0127]Transmission mechanism parameters and reaction vessel parameters are shown in Tables 4 and 5.

[0128]

[0129] Table 4 Transmission mechanism parameters

[0130] project Motor (r / min) speed ratio Movable grinding tool (r / min) Abrasive radius r / m Linear speed m / s Frequency / Hz parameter 3000 2 6000 0.08 50.3 50

[0131] Table 5 Reaction Vessel Parameters

[0132] project inner diameter / cm Section / cm 2 Total height H / cm Effective h / cm Volume / L parameter 20 314.2 40 28 28

[0133] raw material

[0134] Calcium hydroxide (slaked lime, ≥99%) 898.06g

[0135] Carbon dioxide (steel cylinder, 99.8%) 529.18g

[0136] Distilled water 6795.73g

[0137] Steps:

[0138] 1. Equipment installation (such as figure 1 ):

[0139] ① Loosen the upper and lower chuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com