Preparation method of metal-doped black amorphous-state carbon nitride photocatalytic material

A technology of metal doping and catalytic materials, which is applied in the directions of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of simple operation, low cost, and large-scale commercial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

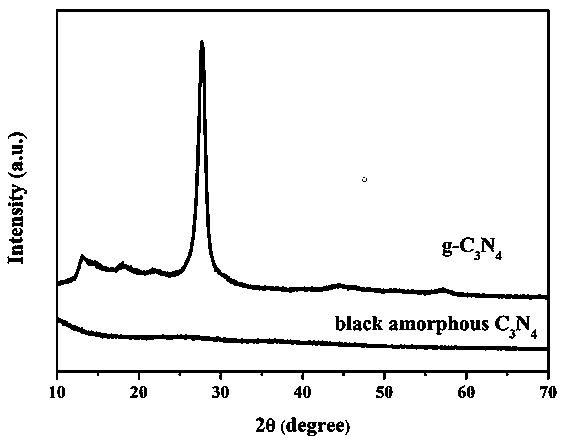

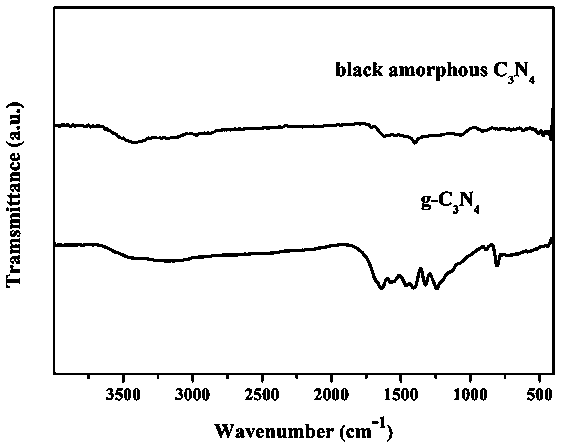

Image

Examples

Embodiment 1

[0025] (1) Mix melamine and ammonium molybdate in a ratio of 100:5.5;

[0026] (2) The above mixture was heated in a tube furnace at 10°C / min to 550°C for 4 hours and then naturally cooled to room temperature to obtain a metal-doped black amorphous carbon nitride photocatalytic material.

Embodiment 2

[0028] (1) Mix melamine and sodium tungstate at a ratio of 100:10.4;

[0029] (2) The above mixture was heated in a tube furnace at 10°C / min to 550°C for 4 hours and then naturally cooled to room temperature to obtain a metal-doped black amorphous carbon nitride photocatalytic material.

Embodiment 3

[0031] (1) Melamine and nickel acetate are mixed in a ratio of 100:7.9;

[0032] (2) The above mixture was heated in a tube furnace at 10°C / min to 550°C for 4 hours and then naturally cooled to room temperature to obtain a metal-doped black amorphous carbon nitride photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com