Methods of generating microparticles and porous hydrogels using microfluidics

A technology of microfluidic devices and microparticles, which can be used in inert gas generation, chemical instruments and methods, microcapsules, etc., and can solve problems such as limited practicability and processing conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

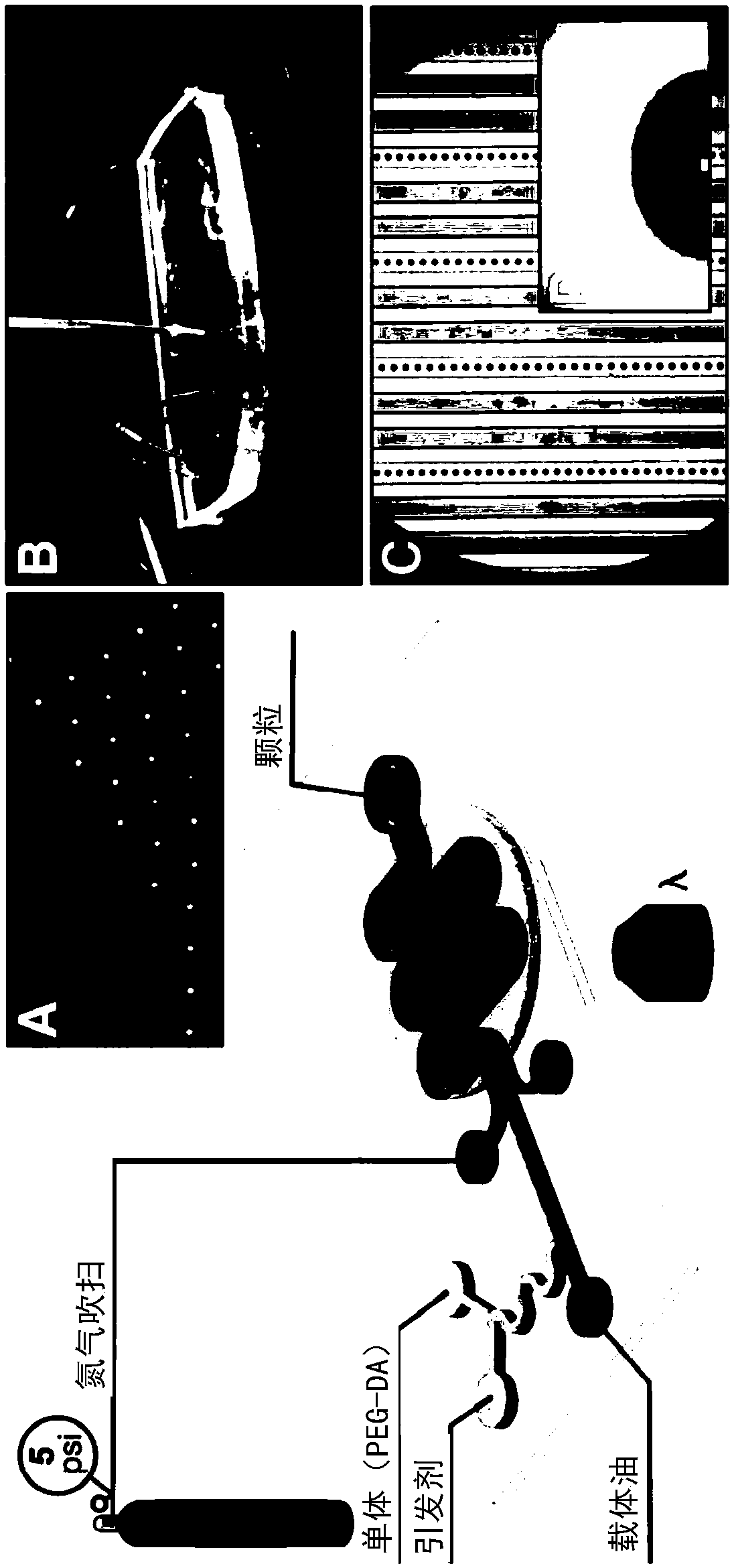

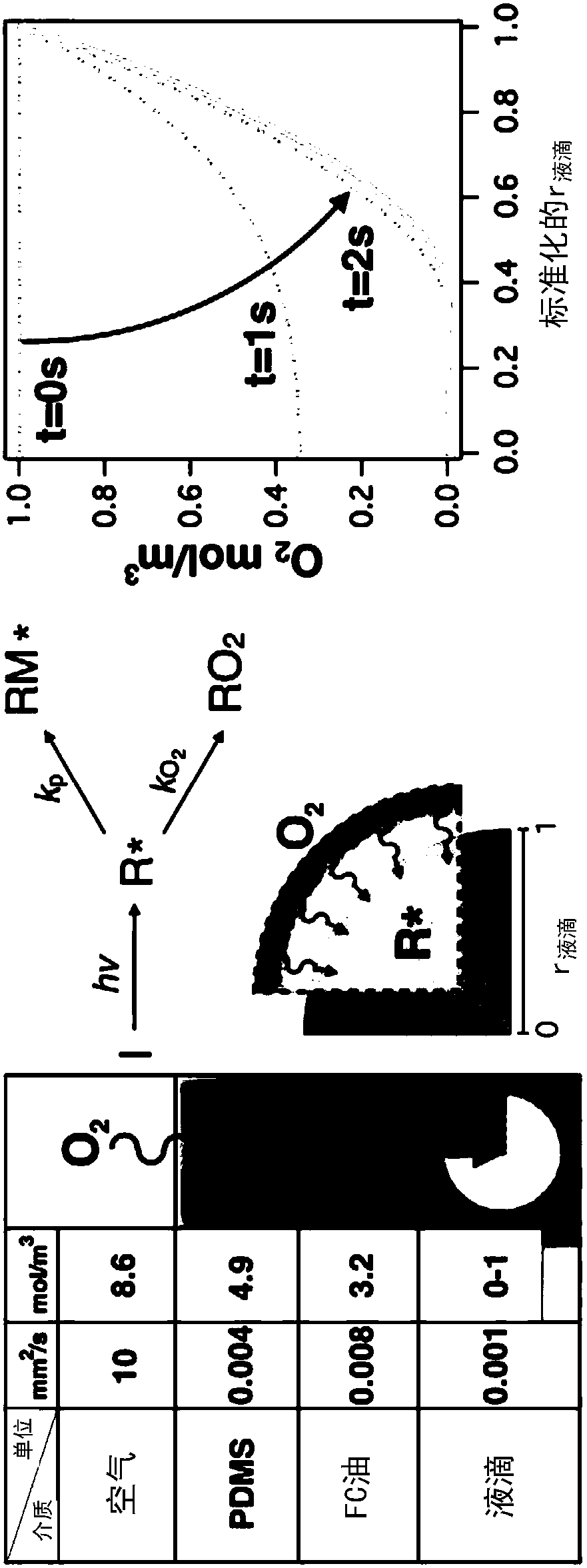

[0081] Example 1: Formation of monodisperse polyethylene glycol diacrylate hydrogel microspheres by oxygen-controlled photopolymerization in a microfluidic device

[0082] Introduction

[0083] Acrylate-based polymers have attracted much attention due to their transparency, color change, robust mechanical properties, and elasticity (Ref. 1.1). Acrylates are readily photopolymerizable on an industrial scale and are widely used in chemical applications as adhesives, sealant composites, and protective coatings (Refs 1.1, 1.2). Acrylates are generally preferred over other synthetic monomers due to their biocompatibility and chemical versatility, allowing modification with a range of monofunctional or multifunctional groups (refs 1.3-1.4). Oligomeric acrylates can be used to produce highly crosslinked networks by photopolymerization methods (ref. 1.5). Based on these features, a class of photopolymerizable polyethylene glycol (PEG)-based hydrogels has been developed around acryla...

Embodiment 2

[0126] Embodiment 2: the method for reducing the oxygen concentration in nitrogen microjacket microfluidic device

[0127] Introduction

[0128] In this example, a nitrogen microjacketed microfluidic device was modified by adding a pre-purification channel for a Novec 7500 to further reduce the oxygen concentration in the device to lower levels. When the nitrogen pressure was increased, less photoinitiator (LAP) was required for the polymerization and correspondingly higher post-encapsulation viability of the cells was obtained. This new method can be used to produce size-controllable microgels that are compatible with commercially available flow cytometry methods that provide high levels of cell viability after encapsulation.

[0129] Materials and methods

[0130] cell culture

[0131] Human lung adenocarcinoma epithelial cells (A549) were used in this study and maintained at 10% fetal bovine serum (Life Technologies, USA), 1% Pen / Strep and 0.2% amphotericin B (Sigma-Aldr...

Embodiment 3

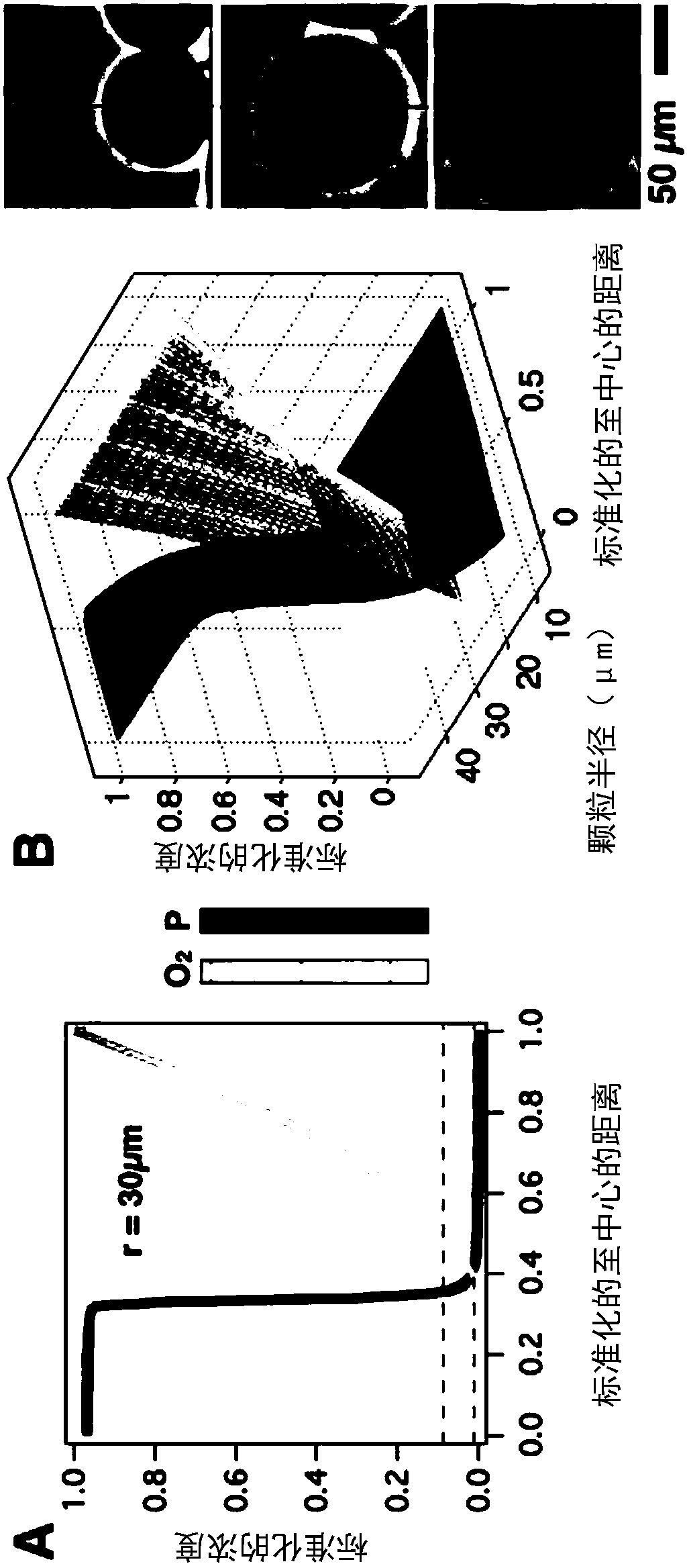

[0160] Example 3: Modeling hydrogel inverse opal structures using photodegradable microparticles

[0161] Inverse colloidal crystals (ICCs) are a product of the lost-wax manufacturing process in which colloidal particles assemble into an ordered matrix in the presence of a liquid continuous phase. The particles are removed after solidification of the continuous phase, leaving behind a structured pore network. ICCs have been developed for various scientific and technological applications, but their practicality is still limited by the harsh processing conditions required to dissolve the particles to form the pore framework.

[0162] In this example, we show a new method for the production of ICCs based on a method involving the synthesis of photodegradable polyethylene glycol diacrylate particles. Since the degradation of the particle phase requires only optical illumination, particle assemblies can be eroded within tightly confined microchannels, creating a microfluidic-integ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com