Preparation method for super hydrophobic biodegradable compound film and product thereof

A composite film and super-hydrophobic technology, applied in coatings, polyester coatings, etc., can solve the problems of easy erosion of organic solvents and difficulty in spreading organic coatings, and achieve the effect of easy industrialization, no need for equipment, and elimination of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

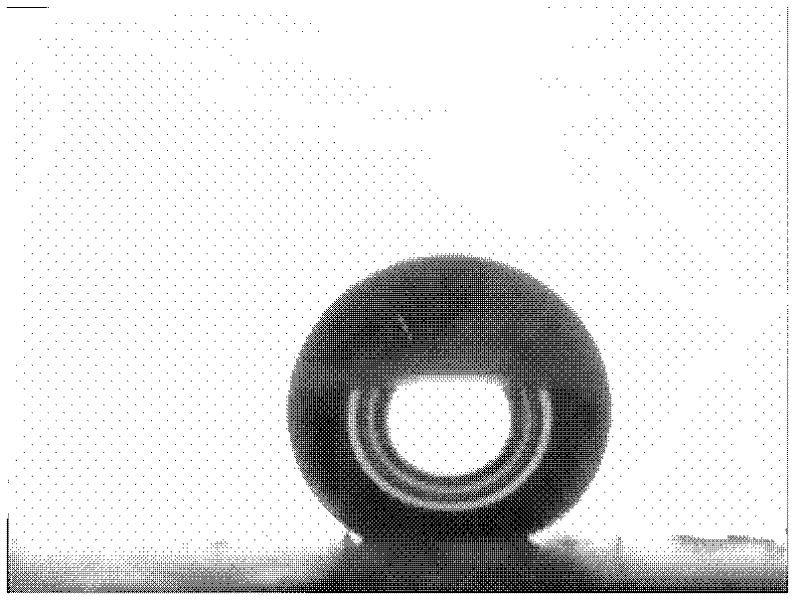

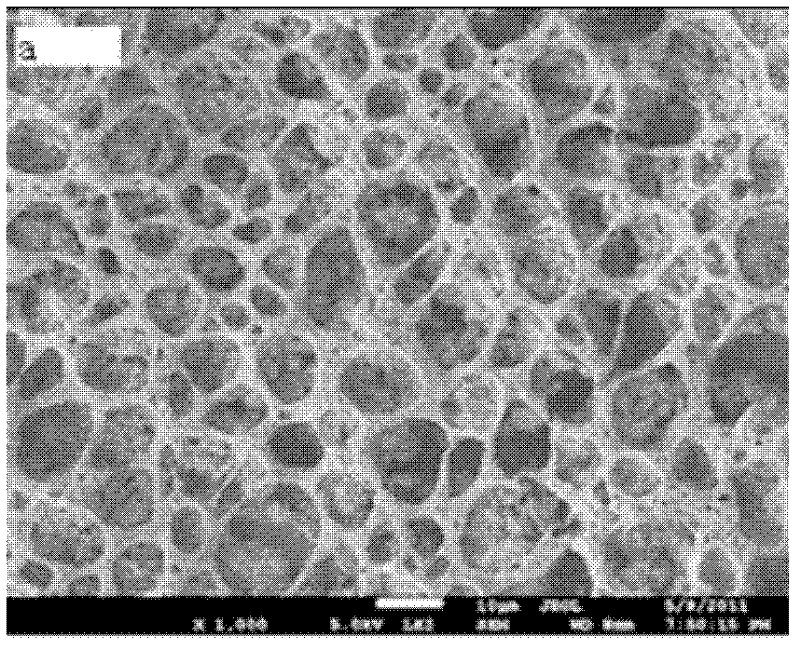

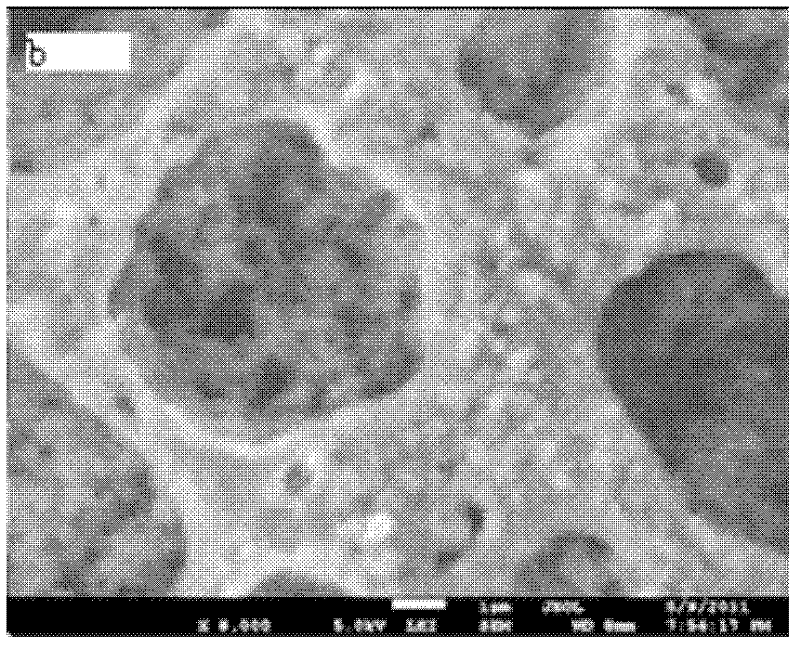

[0023] Example 1: Dissolve 1.5g of polylactic acid (NatureWork LLC, 3051D, USA) in 60g of chloroform at 60°C, stir to form a transparent solution, and then add 0.8g of hydrophobic dioxide with an average particle size of 18nm. Silicon (Evonik Degussa, R972) was stirred for 2 hours and cooled to room temperature to obtain a uniformly dispersed mixture.

Embodiment 2

[0024] Example 2: Dissolve 1.5g of polylactic acid (NatureWork LLC, 3051D, USA) in 60g of chloroform at 60°C, stir to form a transparent solution, and then add 0.5g of hydrophobic dioxide with an average particle size of 18nm. Silicon (Evonik Degussa, R972) was stirred for 2 hours and cooled to room temperature to obtain a uniformly dispersed mixture.

Embodiment 3

[0025]Example 3: Dissolve 1.5g of polylactic acid (NatureWork LLC, 3051D, USA) in 50g of chloroform at 60°C, stir to form a transparent solution, and then add 0.8g of hydrophobic dioxide with an average particle size of 18nm Silicon (Evonik Degussa, R972) was stirred for 2 hours and cooled to room temperature to obtain a uniformly dispersed mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com