Process for thermal cracking of waste tires

A technology for pyrolysis of waste tires, which is applied in the field of pyrolysis process of waste tires, can solve the problems of increased production process and processing cost, large investment in equipment, long production process, etc., so as to save the shredding process, improve product quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

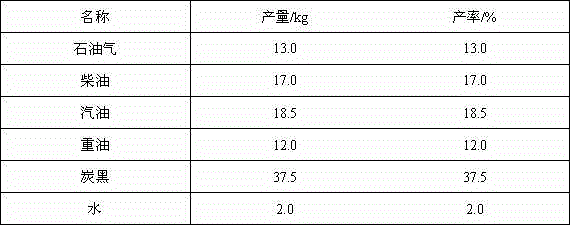

[0021] (1) Clean and remove waste tires with a weight of 100Kg; send the whole tire into the feeding bin for preheating, and the waste nitrogen from the steelmaking plant, which is preheated to 350°C by a low-temperature hot blast stove, continues at a certain flow rate The purpose of preheating the tires is achieved through the feeding bin, and the tires are preheated to 200°C after 15 minutes;

[0022] (2) Send the tires treated in the previous step into the cracking bin, add 1.5Kg of kaolin catalyst and 1.5Kg of activated clay catalyst at the same time, and pass high-temperature nitrogen preheated to 850°C through a high-temperature hot-air stove into the cracking bin. It is not only used as a heating source but also as an inert gas for protection. At the same time, it can also be used as a purge gas to take the cracked gas out of the cracking chamber in time to avoid secondary cracking, so that the high-temperature nitrogen flow can be stabilized to keep the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com