Free falling high-temperature synthesizing method and synthesizing device for IIB-VIA compound powder

A synthesis device and compound technology, applied in the field of IIB-VIA compound powder synthesis, can solve the problems of easy explosion accident, unsafe reaction process, difficult to release quickly, etc., and achieve easy industrial production, convenient operation, easy processing and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

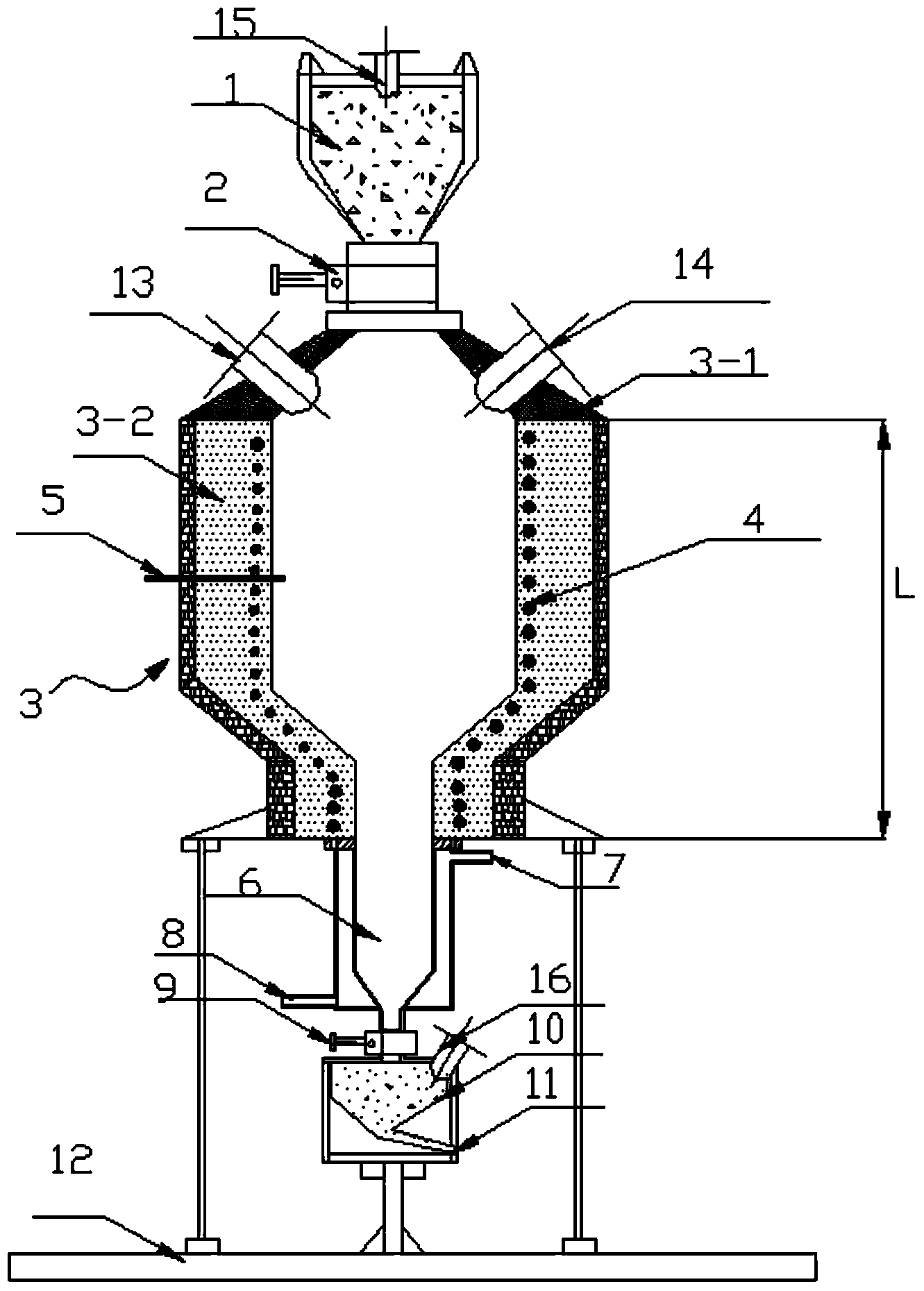

[0032] In this embodiment, the powder material synthesis device such as figure 1 As shown, it includes a furnace body 3, a charging chamber 1, a first valve 2, a second valve 9, a condensation chamber 6 and a collection chamber 10; the furnace body 3 is composed of a heat insulation section 3-1 and a heating section 3-2 , the outer layer of the heat insulation section 3-1 is made of ceramic fiber blanket, and the inner layer is made of 3N quartz, on which an air inlet 13 for connecting with a protective gas source and a first gas outlet for connecting with a vacuum pump are arranged 14. The outer layer of the heating section is made of ceramic fiber blanket, the inner layer is made of 3N quartz, and the length L is 200cm. The heating section is equipped with a heating device 4 and a temperature control thermocouple 5, and the heating device is a resistance heating device; The condensing chamber 6 is made of 3N quartz, the chamber body wall is a sandwich structure, the chamber ...

Embodiment 2

[0034] In this embodiment, the powder material synthesis device such as figure 1 As shown, it includes a furnace body 3 , a charging chamber 1 , a first valve 2 , a second valve 9 , a condensation chamber 6 and a collection chamber 10 . The differences from Example 1 are: 1. The length L of the heating section 3-2 is 100 cm; 2. The heating device 4 installed in the heating section is an induction heating device.

Embodiment 3

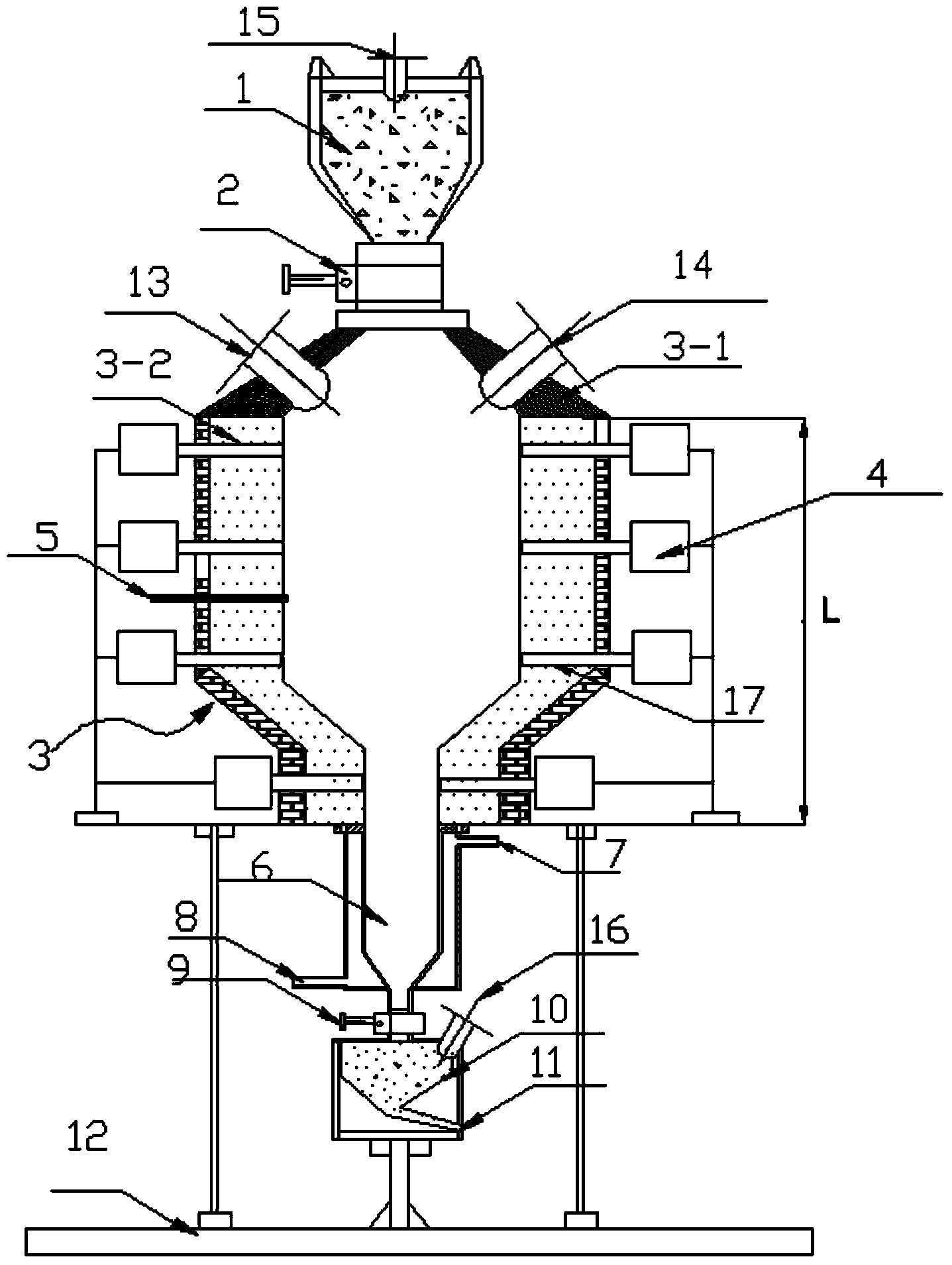

[0036] In this embodiment, the powder material synthesis device such as figure 2 As shown, it includes a furnace body 3 , a charging chamber 1 , a first valve 2 , a second valve 9 , a condensation chamber 6 and a collection chamber 10 . The differences from Example 1 are: 1. The length L of the heating section 3-2 is 40 cm; 2. The heating device 4 installed in the heating section 3-2 is a microwave generator, which is connected to the heating section through a waveguide 17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com