On board inert gas generation system

An inert gas, generation system technology, used in inert gas generation, aircraft parts, air handling equipment, etc., can solve problems such as motor inefficiency, speed limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

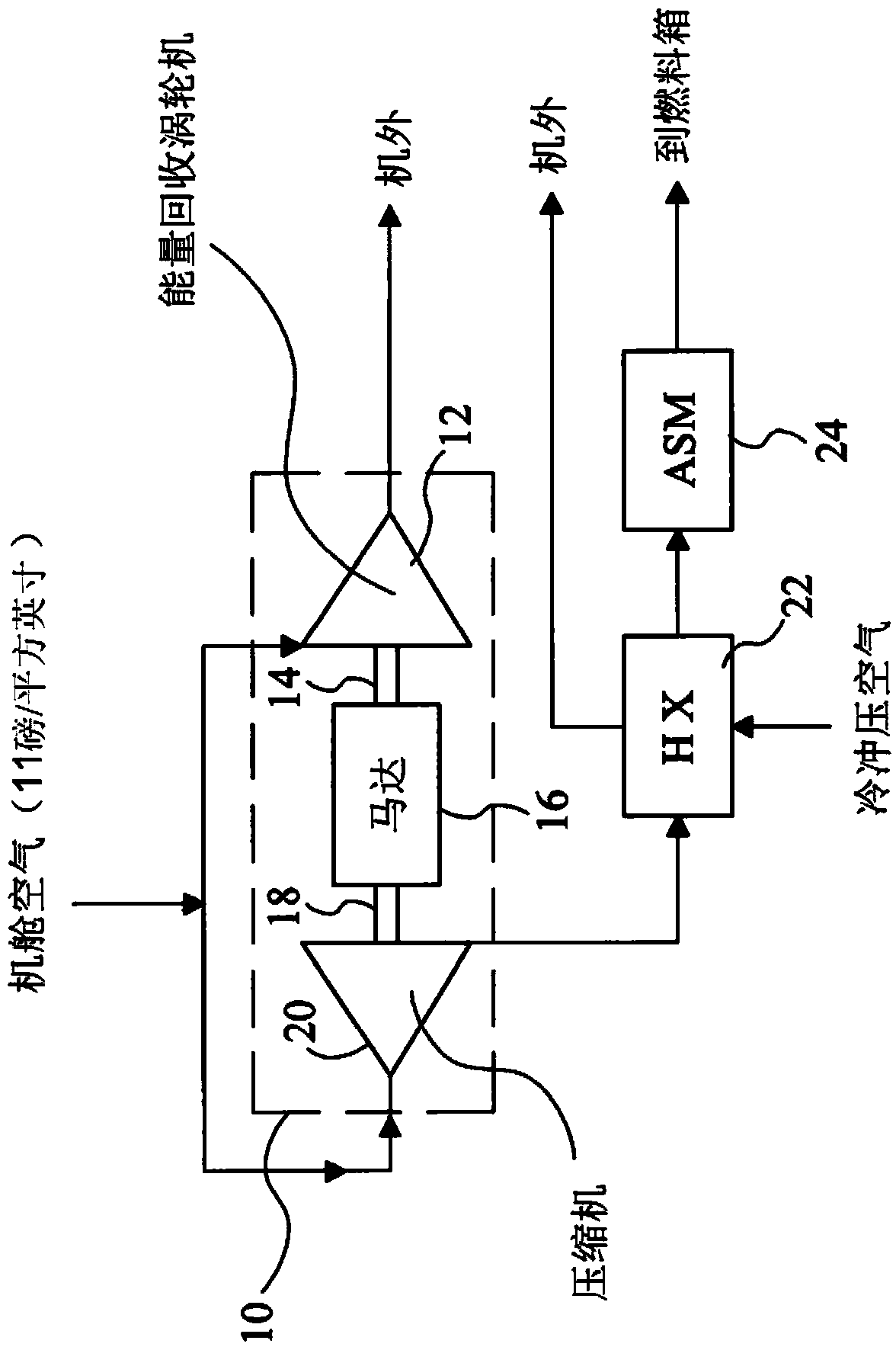

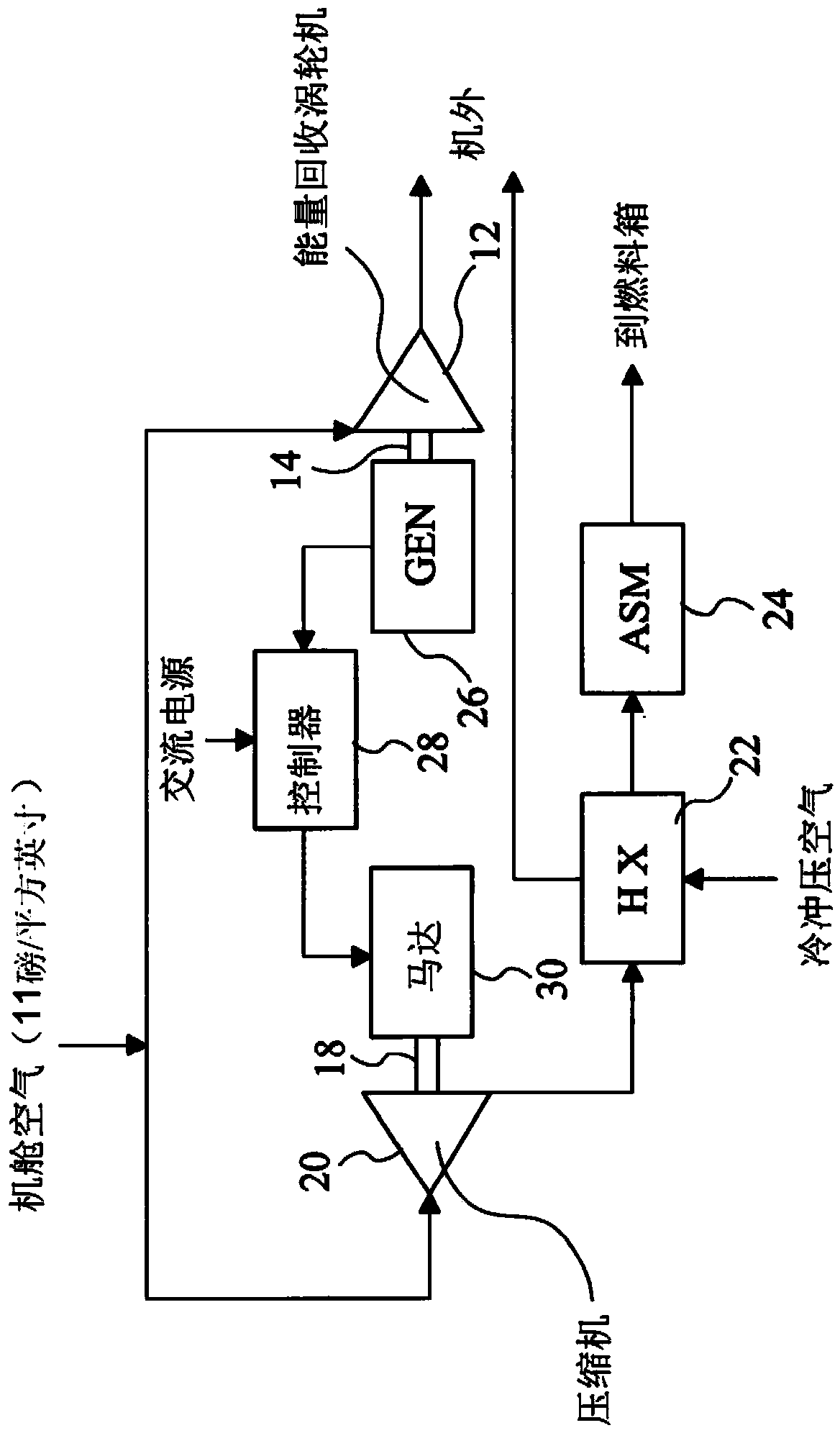

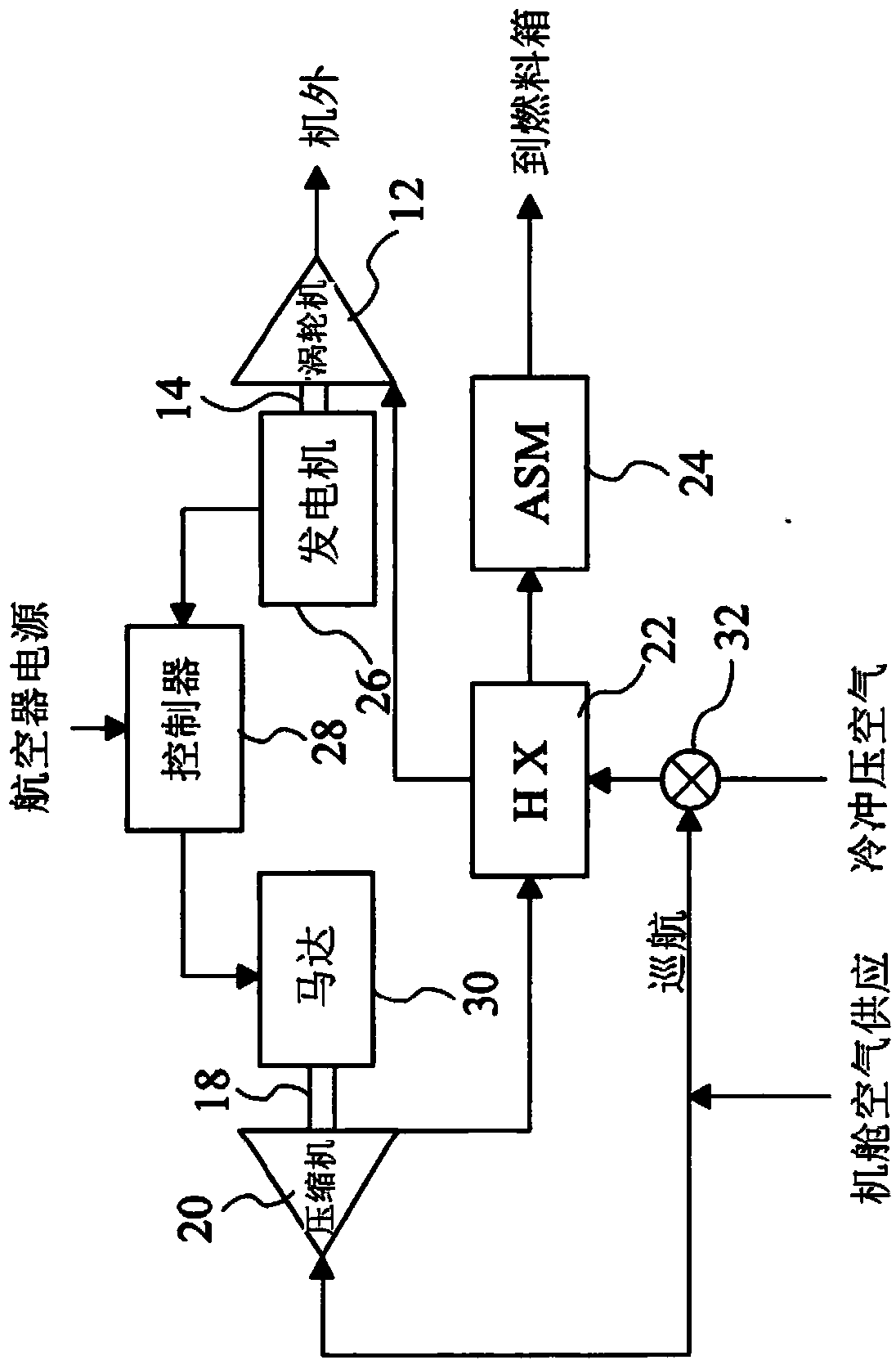

[0045] The embodiments described below employ mechanically and / or electrically driven variable speed positive displacement booster compressors to supply air to the gas separation module at the appropriate pressure and flow to inert the aircraft's fuel tanks. An energy recovery turbine is integrated with the compressor to reduce electricity consumption by supplying cabin air to the compressor and turbine.

[0046] These embodiments use cabin air provided by the aircraft's environmental control system (ECS), which requires power from the propulsion engines and increases the specific fuel consumption of the engines. After the air is circulated in the cabin, it is discharged to the atmosphere as exhaust gas through the external exhaust valve. Using this air for fuel tank inerting purposes does not cause an additional increase in Specific Fuel Consumption (SFC), since the required energy is already taken up by the ECS. Cabin pressure is typically 11 or 12 psi at cruising altitude,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com