Gas-liquid two-phase mixed low-temperature nitrogen gas jet flow generation apparatus

A gas-liquid two-phase flow and generating device technology, which is applied in the direction of fluid mixers, mixers, inert gas generation, etc., can solve problems such as coordinated control, and achieve the effects of fast generation time and great application flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

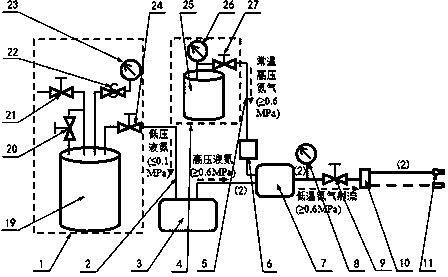

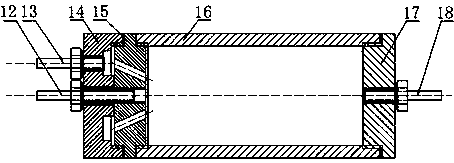

[0022] see figure 1 ,, the gas-liquid two-phase flow hybrid low-temperature nitrogen jet generating device of the present invention includes a self-pressurized liquid nitrogen supply system 1, a high-pressure low-temperature hose 2, a reciprocating low-temperature booster pump 3, a normal temperature nitrogen supply system 4, a high-pressure normal temperature Hose 5, dry filter 6, inner mixing chamber 7, pressure gauge 8, shut-off valve 9, three-way valve 10 and nozzle 11.

[0023] read on figure 1, the self-pressurized liquid nitrogen supply system 1 is connected to the inlet of the reciprocating cryogenic booster pump 3 through a high-pressure resistant low-temperature hose 2 to generate low-pressure liquid nitrogen (≤0.1MPa) and deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com