Short connecting device

A short-circuit and plug-in rod technology, which is applied to the parts of the connection device, coupling device, connection, etc., can solve the problems of open circuit of the secondary circuit of the current transformer, easy loosening of the short-circuit joint, and endangering personal safety, etc. Productivity, Convenience, and Reliable Connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

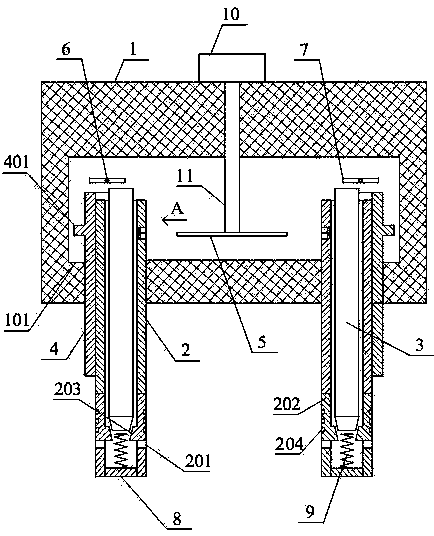

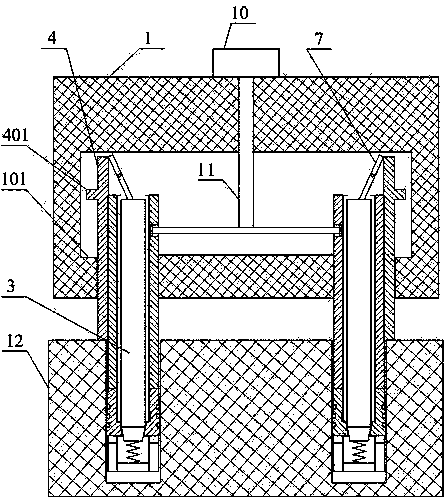

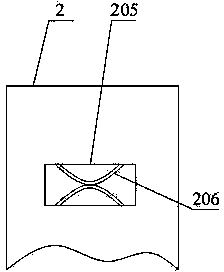

[0034] Such as Figure 1~Figure 4 As shown, a shorting device includes a fixed body 1, an insertion rod 2, an expansion rod 3, a sliding half-circle sleeve 4, a conduction bar 5, a rotating shaft 6 and a pressing bar 7, a knob 10 and a connecting shaft 11; the insertion rod 2 It is a hollow cylinder, and the outer surface of the insertion rod 2 is provided with a symmetrical hole 201, and an expansion strip 202 is arranged in the hole 201. The upper end of the expansion strip 202 is connected with the hole wall of the hole 201, and the other parts of the expansion strip 202 are not connected with the hole. The hole wall of 201 contacts, and the inner surface of the expansion bar 202 is provided with a protrusion 203; the expansion rod 3 is slidably arranged in the insertion rod 2, the top of the expansion rod 3 is located outside the insertion rod 2, and the bottom end of the expansion rod 3 is Tapered, the bottom end of the expansion rod 3 is located above the protrusions 203...

Embodiment 2

[0039] Such as figure 1 and figure 2 As shown, this embodiment is based on Embodiment 1, and the outer surface of the expansion strip 202 is provided with a plurality of anti-slip grooves 204 .

Embodiment 3

[0041] Such as figure 1 and figure 2 As shown, this embodiment is based on any one of the above-mentioned embodiments, the bottom end of the insertion rod 2 is provided with a sealing plate 8 ; and a spring 9 fixed on the upper surface of the sealing plate 8 is also included.

[0042] After the short-circuit plug is inserted into the secondary circuit socket 10 of the current transformer, the bottom end of the expansion rod 3 compresses the spring 9, and after the short-circuit plug is taken out, the spring 9 pushes the expansion rod 3 upward, so that the bottom end of the expansion rod 3 is separated The protruding part 203, the expansion rod 3 and the expansion strip 202 automatically reset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com