Starter motor with idle gear

A starter motor and idler technology, which is applied in the direction of engine starting, electric components, engine components, etc., can solve the problems of increasing the number of parts, increasing the cost, and increasing the assembly time, so as to reduce the number of parts, improve the reliability, and achieve a simple implementation. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

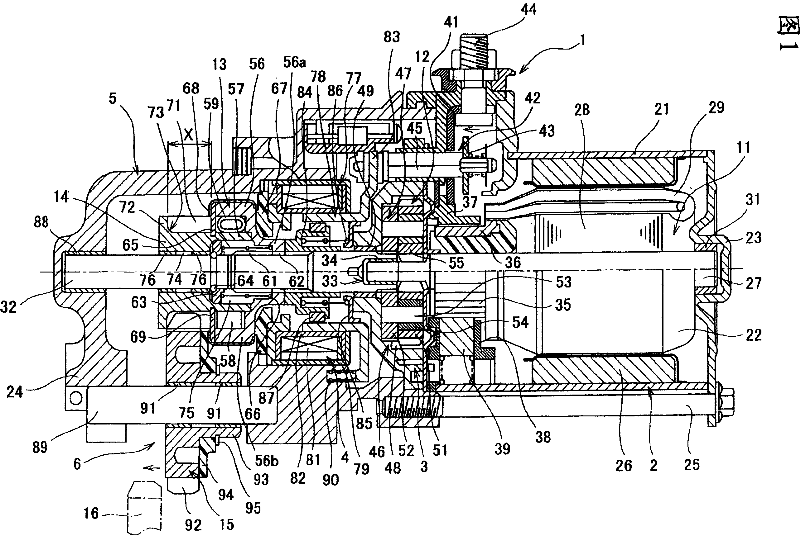

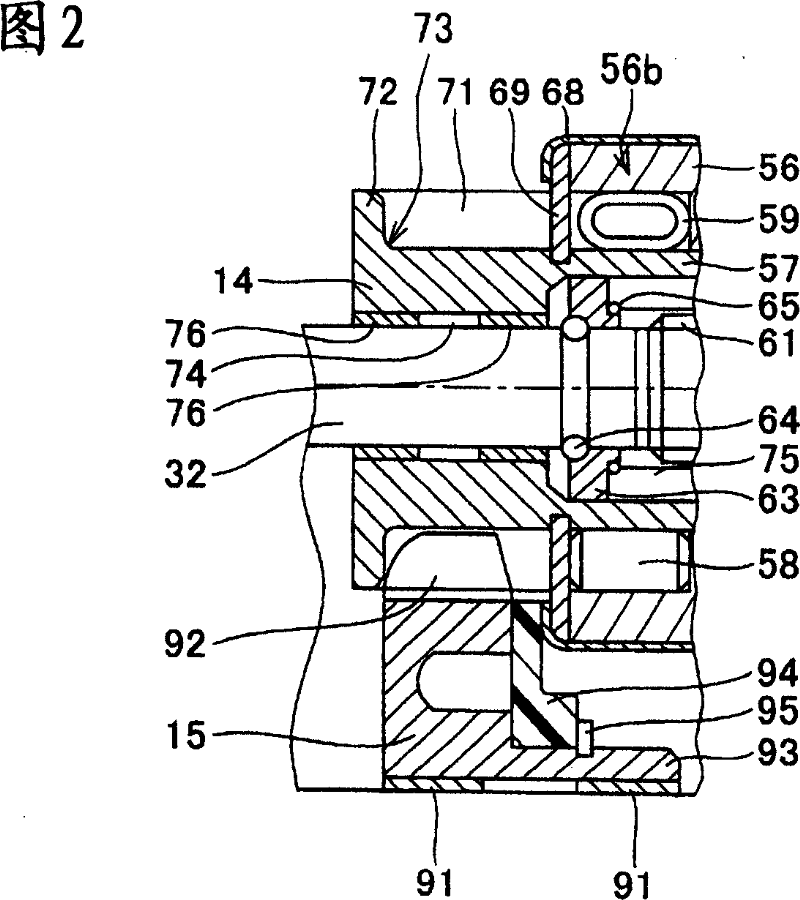

[0031] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. 1 is a sectional view showing the structure of a starter motor according to an embodiment of the present invention, and FIG. 2 is an enlarged view of main parts of the starter motor of FIG. 1 . The starter motor 1 shown in FIG. 1 is used to start an automobile engine, and rotates the stopped engine to perform the necessary rotations for intake, atomization, compression, and ignition of fuel.

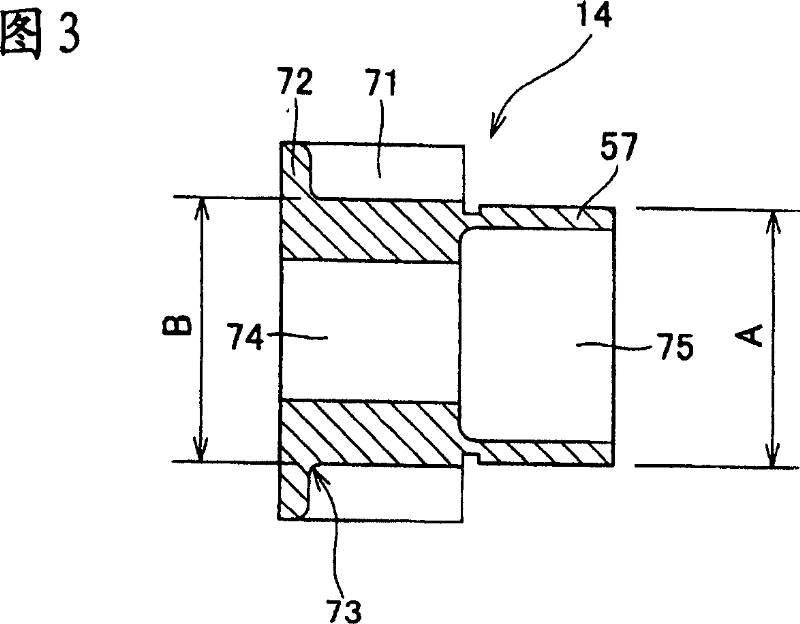

[0032]The starter motor 1 is roughly composed of a motor unit 2 , a gear unit 3 , a magnetic switch unit 4 , a case unit 5 , and an idle unit 6 . The motor unit 2 is provided with a motor (electric motor) 11 as a driving source, and the gear unit 3 is provided with a planetary gear mechanism 12 , an overrunning clutch 13 , a pinion 14 and the like as a speed reduction device. An idler gear 15 that meshes with the pinion gear 14 is provided on the idler portion 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com