Autoanalyzer and dispensing apparatus

A technology of automatic analysis device and dispensing nozzle, which is applied in the direction of analyzing materials and instruments, can solve the problems of large device size, reduced processing capacity, complex mechanism, etc., and achieve the effect of simplifying the structure of the device and reducing the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Embodiments of the present invention will be described in detail below based on the drawings. In addition, in all the drawings for explaining the present embodiment, members having the same function are attached with the same symbols in principle, and overlapping descriptions are omitted as much as possible.

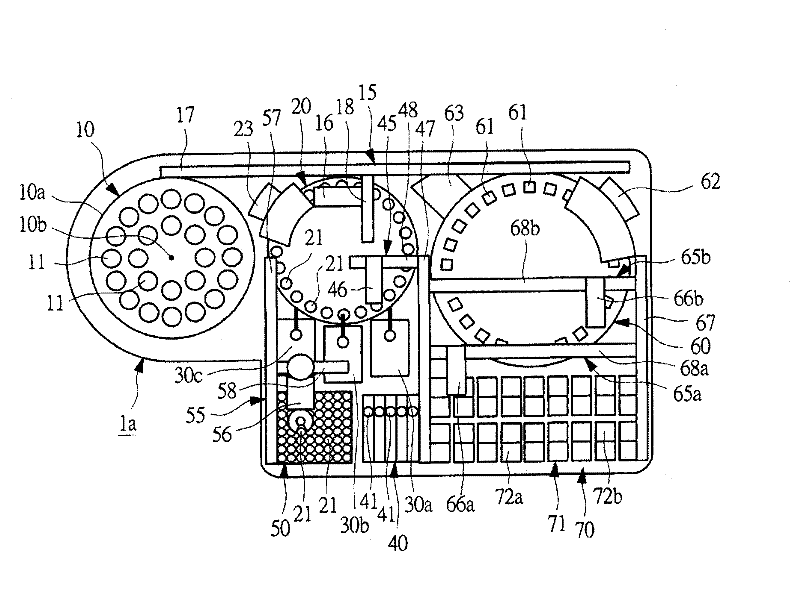

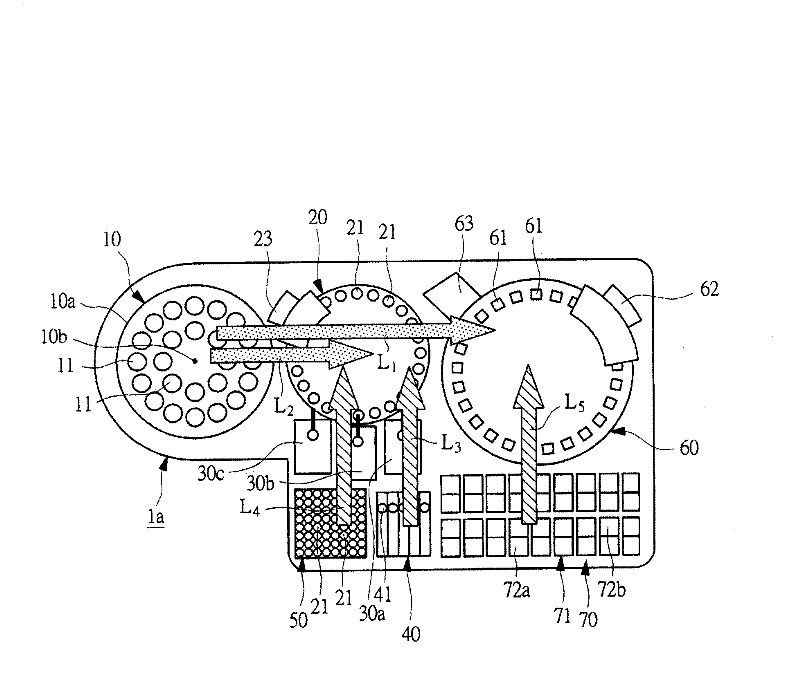

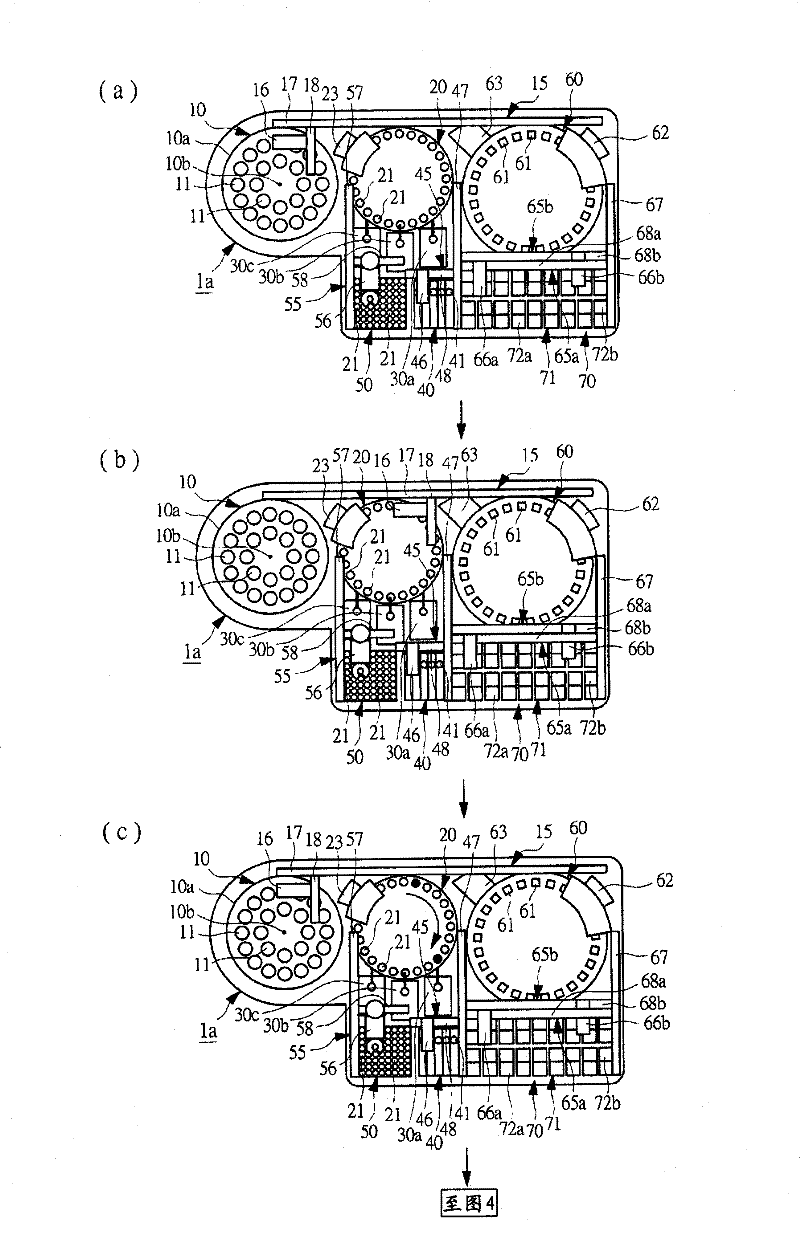

[0082] figure 1 It is a schematic plan view showing the outline of one embodiment of the automatic analyzer of the present invention, figure 2 yes means figure 1 The flow diagram of the sample, pretreatment solution, reagent, etc. in the automatic analysis device of image 3 (a)~(c), Figure 4 (a)~(c) and Figure 5 (a)~(c) are explained sequentially figure 1 An explanatory diagram of an example of the operation flow in the automatic analyzer. Image 6 is description figure 1 An explanatory diagram of another example of the operation flow in the automatic analyzer. In addition, in figure 2 In , illustration of the sample dispensing mechanism is omitted f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com