Method for producing low alloyed steel continuous casting circular tube blank with a diameter of 350-400mm

The invention relates to a low-alloy steel and production method technology, which is applied in the production field of continuous casting round tube billets of low-alloy steel with a diameter of Ф350-Ф400mm, and can solve problems such as excessive deformation of the billet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The production method of the low-alloy steel continuous casting circular tube billet with a diameter of Φ350-Φ400mm of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0057] The following takes the Φ400mm billet as an example to illustrate:

[0058] 1. Select the round tube billet crystallizer process conditions when the ratio of the arc radius R of the continuous casting machine to the diameter D of the low alloy steel continuous casting round tube billet is R / D = 26.25 ~ 30

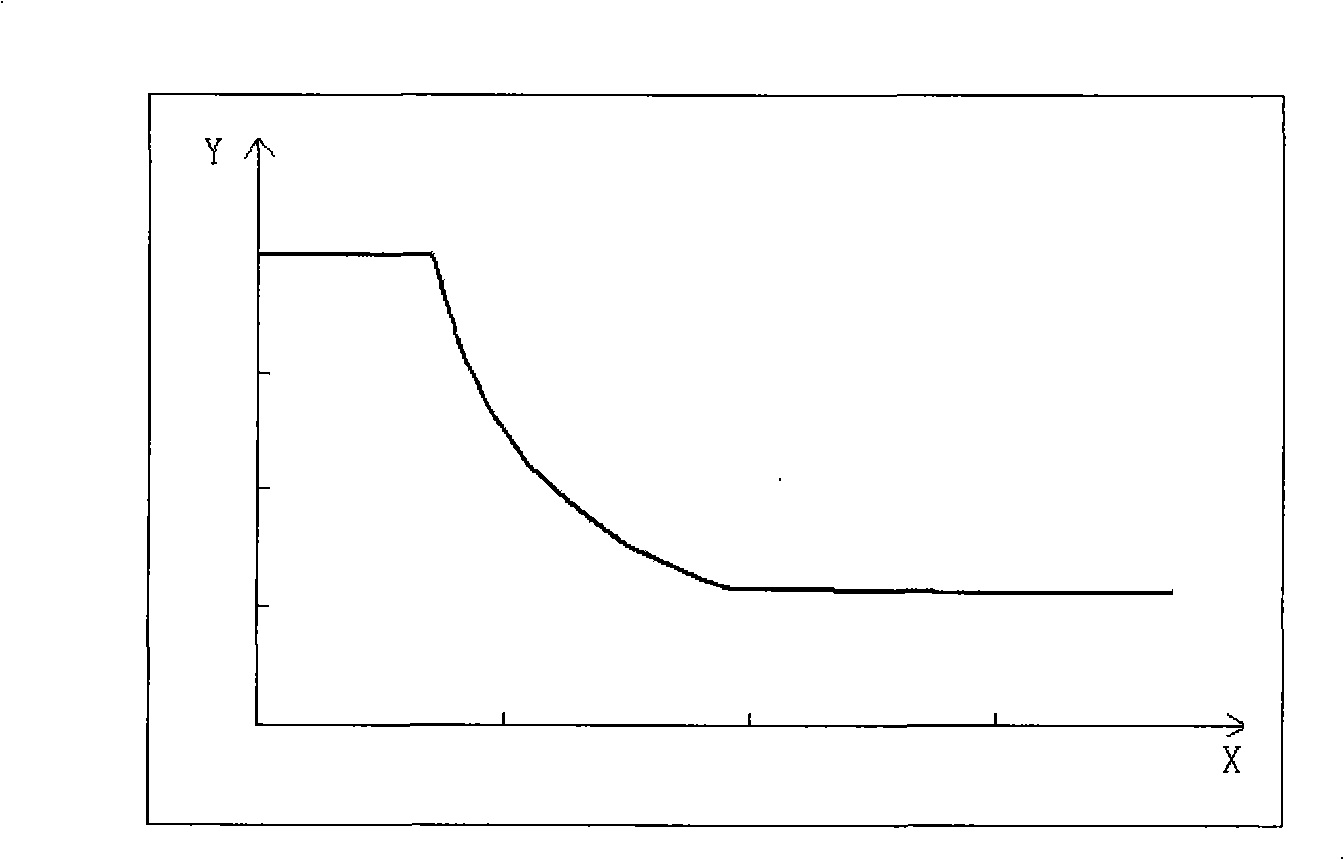

[0059] ① Mold copper tube taper design, such as figure 1 As shown, the following two equations (1) and (2) can be used to describe the change curve of the taper along the longitudinal direction of the copper tube:

[0060] y=a 0

[0061] y = a - b ( x - 75 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com