Plate-belt temperature monitoring method during hot-rolled strip steel stream cooling process

A laminar flow cooling and hot-rolled strip technology, applied in the direction of temperature control, etc., can solve the problems that the transient temperature of the strip cannot be predicted, the model does not reflect the relationship between the strip points, and the model accuracy requirements are strict, etc., to achieve a wide range of steel types, The effect of improving monitoring accuracy and good convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

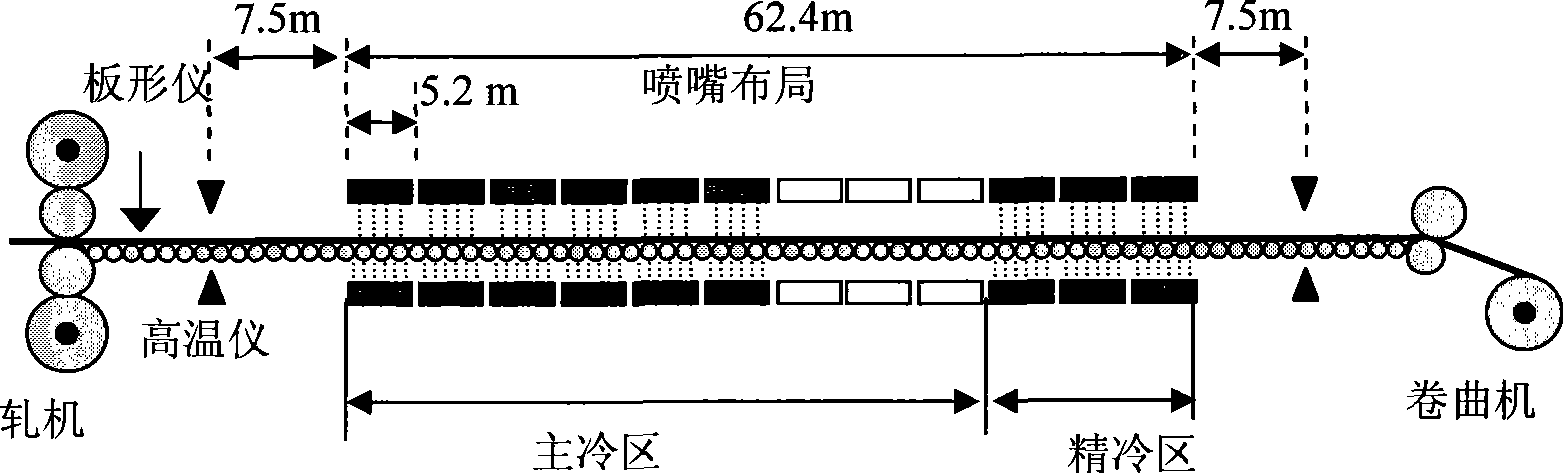

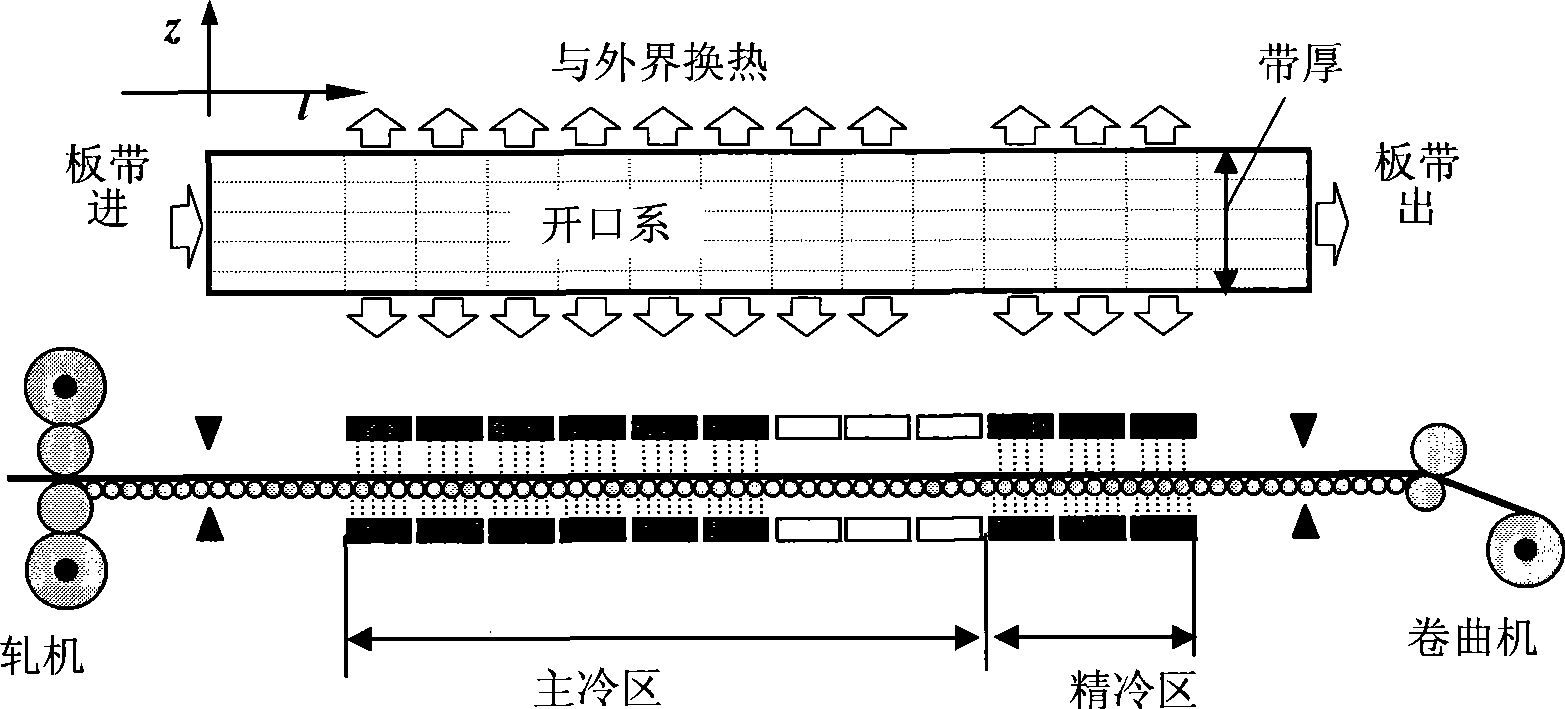

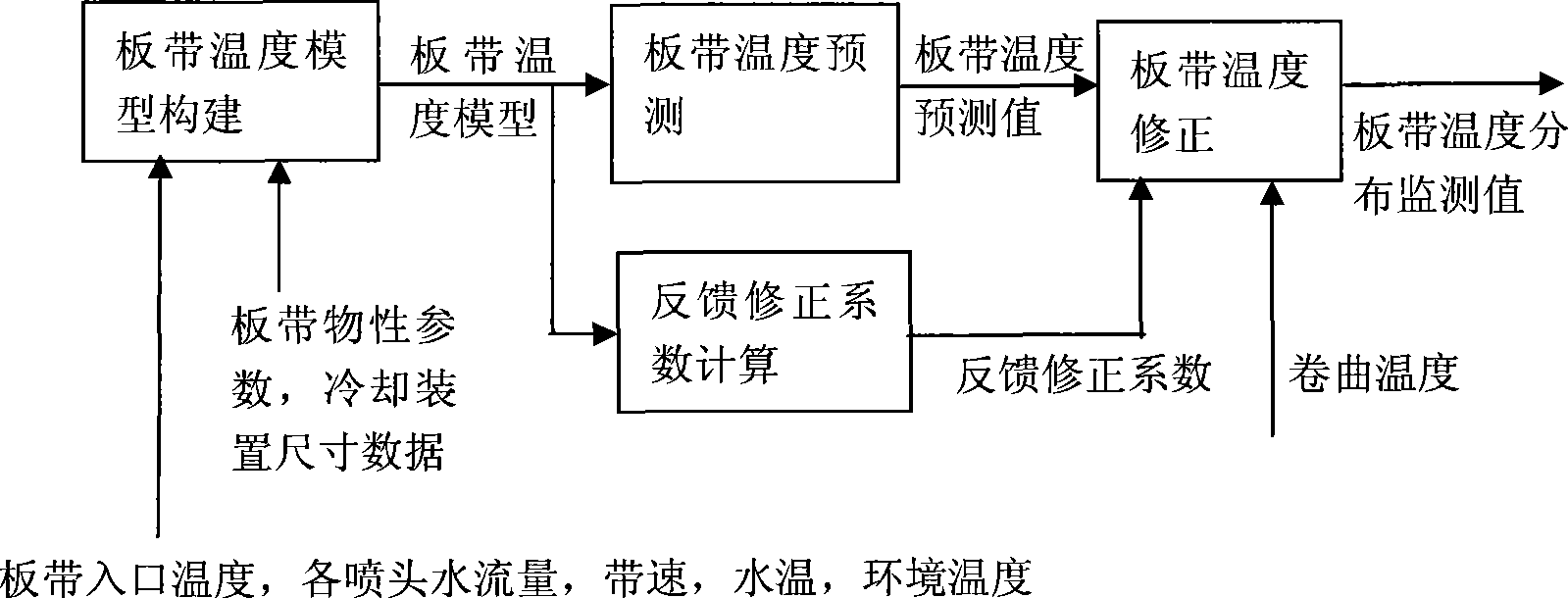

[0023] This embodiment is applied to the laminar flow cooling process of hot-rolled steel strip. Such as figure 1 As shown, the laminar flow cooling equipment is divided into the main cooling area (46.8m) and the fine cooling area (15.6m). It consists of 12 groups of nozzles, and the distance between each group of nozzles is 5.2m. The temperature of strip steel after finishing rolling is about 800-920℃, cooled to 510-680℃ by cold flow cooling equipment, and finally coiled into coils by coiler. Strip parameters are as follows:

[0024] The thermal conductivity coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com