Method for preparing anatase-phase titanium dioxide sol

A titanium dioxide, anatase phase technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effect of wide range of materials, low cost and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

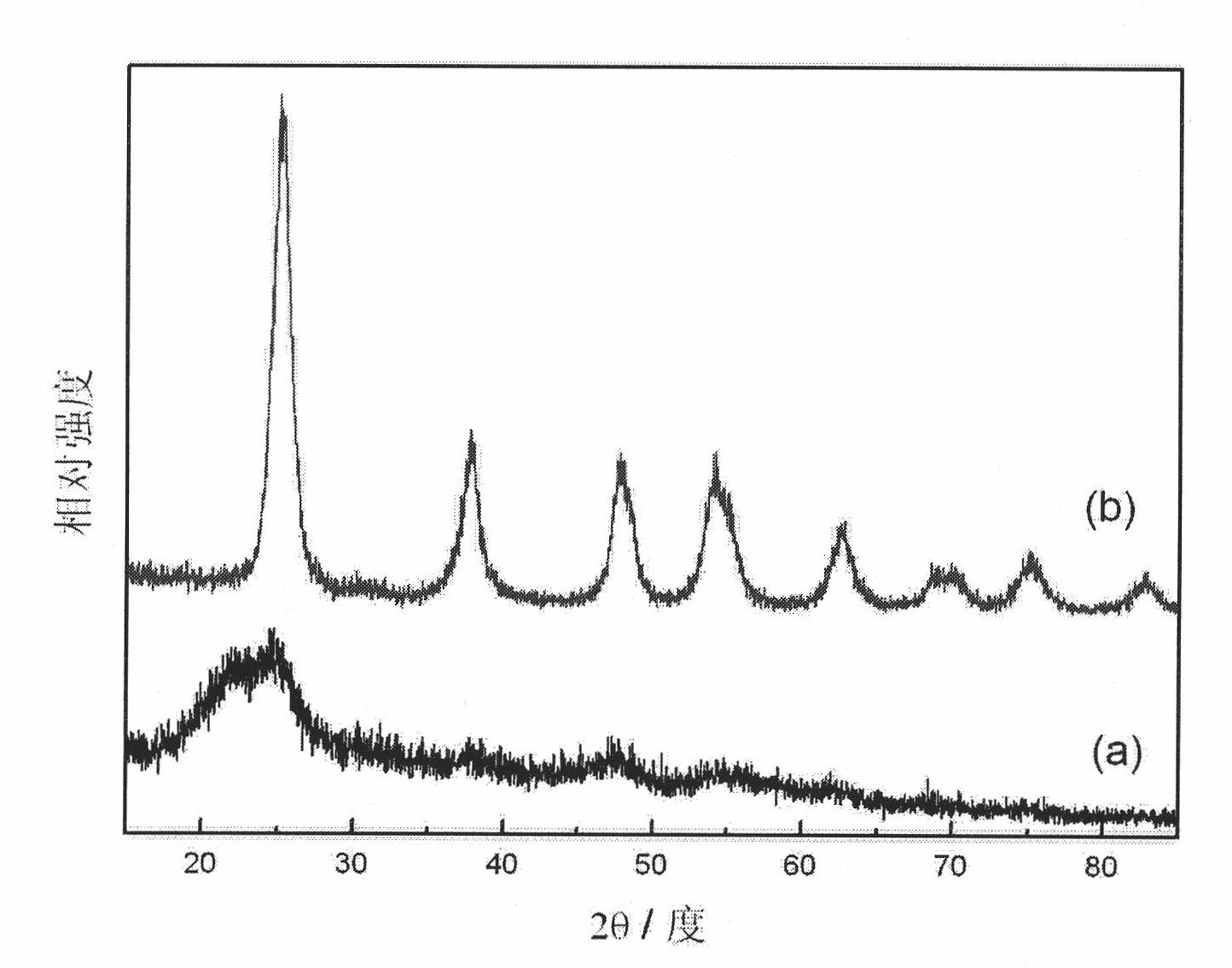

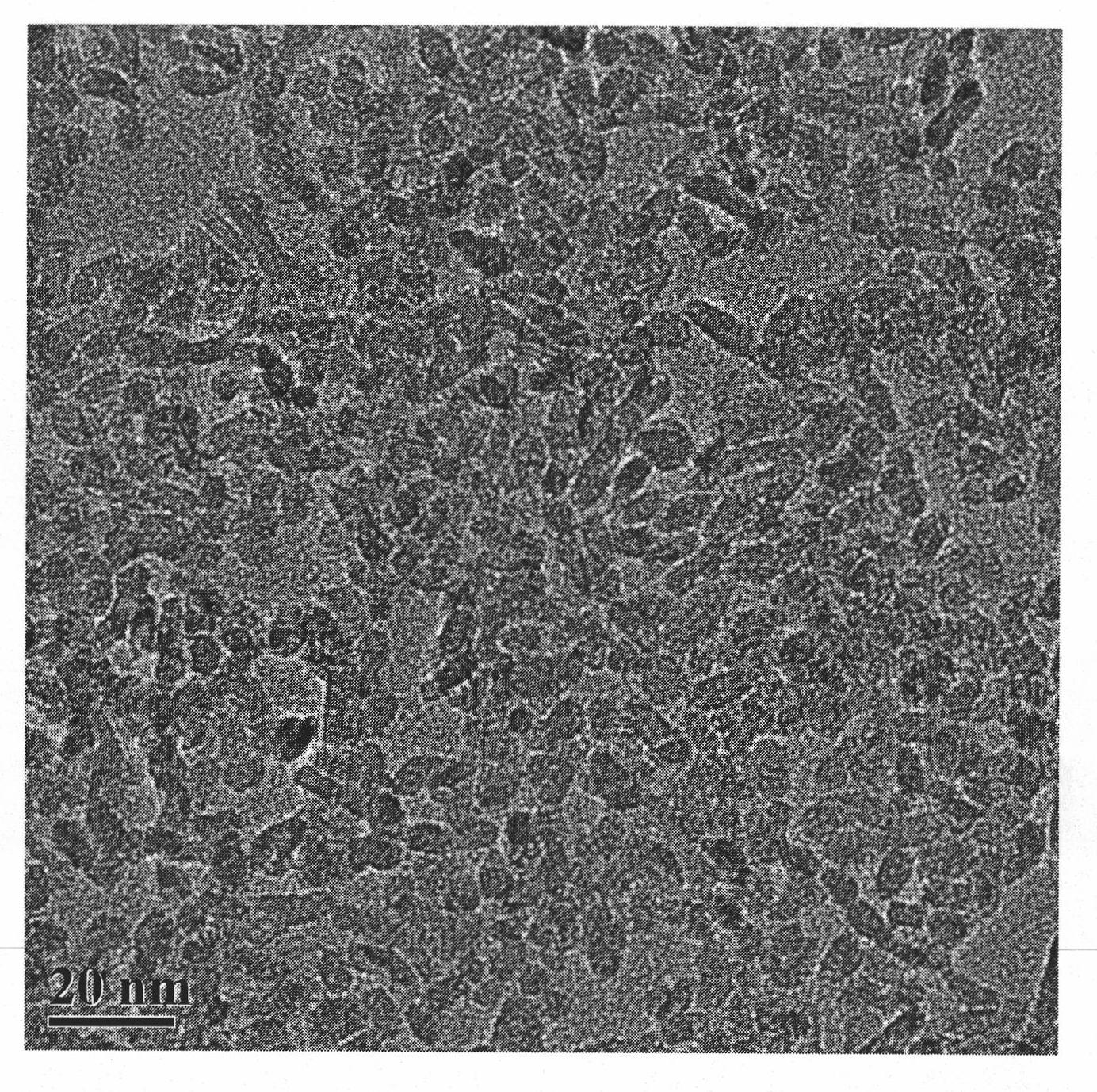

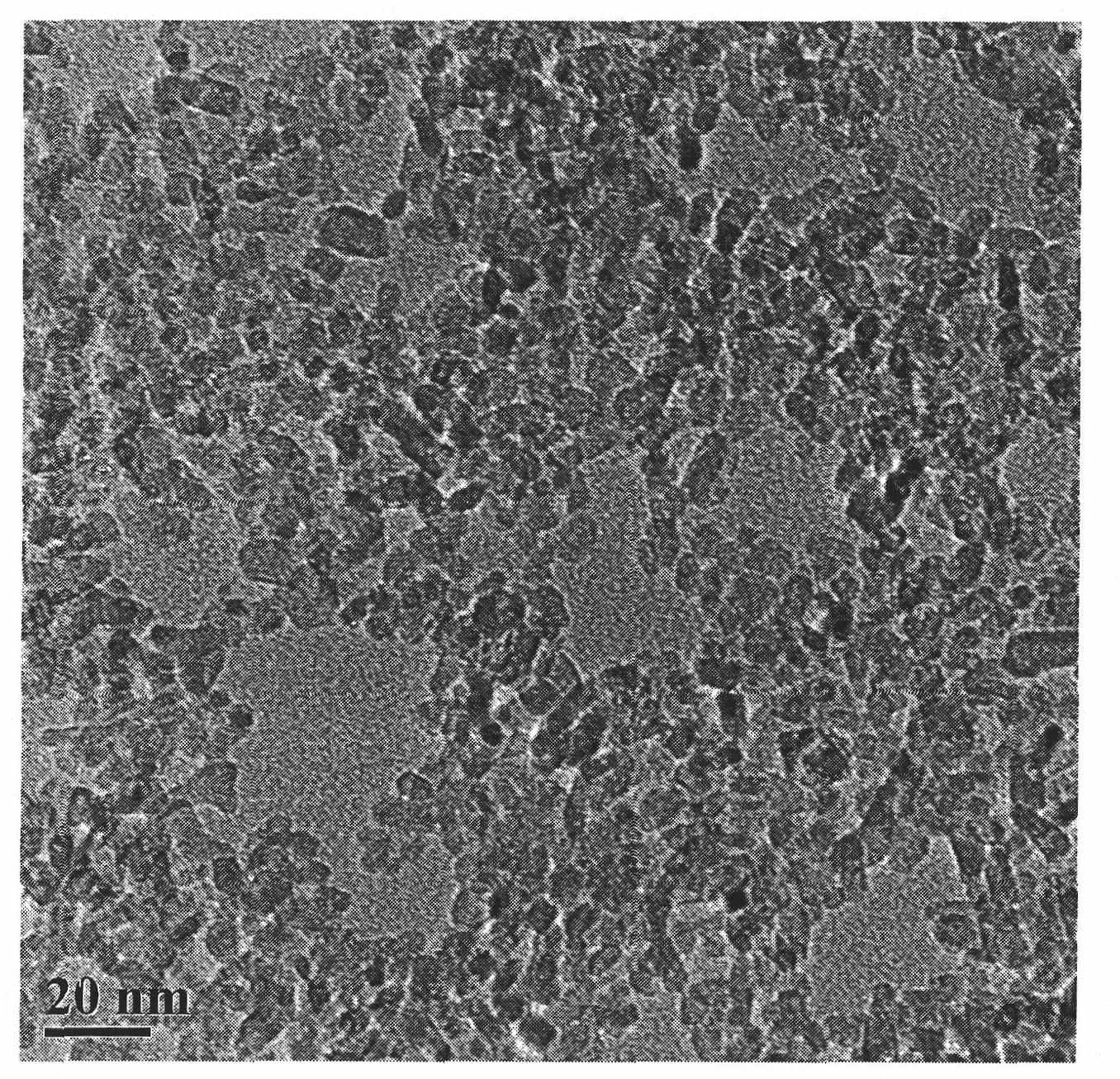

[0033] Heat 100 mL of titanium sulfate solution with a concentration of 1 mol / L to 70°C and keep it warm, add 200 mL of 2 mol / L sodium hydroxide solution dropwise, and keep warm for 2 hours after the dropwise addition to obtain a white precipitate. After the heat preservation was completed, it was naturally cooled to room temperature, the product was poured out, and washed repeatedly with deionized water to obtain a gel-like solid. Weigh 80 grams of the above solid (equivalent to 8 grams of titanium dioxide) and disperse it in 100 mL of trifluoroacetic acid with a concentration of 1 mol / L. The temperature is kept at 20 ° C, accompanied by stirring and ultrasonic dispersion, and kept for 12 hours to obtain transparency. better sol. Take 50ml of the above sol, pour it into a hydrothermal kettle with a volume of 80ml for hydrothermal reaction, raise the temperature to 200°C and keep it warm for 24 hours, centrifuge the obtained gelatinous white precipitate, then disperse it in di...

Embodiment 2

[0037] Heat 200mL of titanium tetrachloride solution with a concentration of 2mol / L to 50°C and keep it warm, add 300mL of ammonia water with a concentration of 3mol / L dropwise, and continue to keep warm and hydrolyze for 24 hours after the dropwise addition to obtain a white precipitate. At the end of the heat preservation, it was naturally cooled to room temperature, the product was poured out, and washed repeatedly with deionized water to obtain a gel-like solid. Weigh 60 grams of the above solid (equivalent to 9 grams of titanium dioxide) and place it in a beaker, then measure 75 mL of trichloroacetic acid with a concentration of 0.5 mol / L and 75 mL of trifluoroacetic acid with a concentration of 1.5 mol / L, and mix the two acid solutions Add it into the above beaker containing the gel solid, keep the temperature at 5°C, stir, ultrasonically disperse, and keep for 24 hours to obtain a transparent sol. Dilute the obtained sol 5 times with distilled water (volume ratio), take...

Embodiment 3

[0040] After heating 400 mL of 0.25 mol / L titanium sulfate solution to 90°C, 400 mL of 1 mol / L ammonia solution was added dropwise to the solution, and hydrolyzed at 90°C for 12 hours to obtain a white precipitate. At the end of the heat preservation, it was naturally cooled to room temperature, the product was poured out, and washed repeatedly with deionized water to obtain a gel-like solid. Weigh 100 grams of the above solid (equivalent to 12 grams of titanium dioxide) and disperse it in a mixed solution of 50 mL of acetic acid with a concentration of 0.75 mol / L and 50 mL of trifluoroacetic acid with a concentration of 1.25 mol / L. , Ultrasonic dispersion, and keep for 4 hours to obtain a transparent sol. After diluting the obtained sol 10 times with distilled water, take 50ml and pour it into a hydrothermal kettle with a volume of 80ml for hydrothermal reaction, raise the temperature to 120°C and keep it warm for 4 hours, centrifuge the obtained white precipitate, then dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com