Preparation method of in-situ defect modified Co9S8-porous nitrogen-doped carbon electrode

A nitrogen-doped carbon, co9s8- technology, applied in fuel cell type half cells and primary cell type half cells, battery electrodes, circuits, etc., can solve problems such as limited electrocatalytic performance and aggravating the surface of catalyst substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

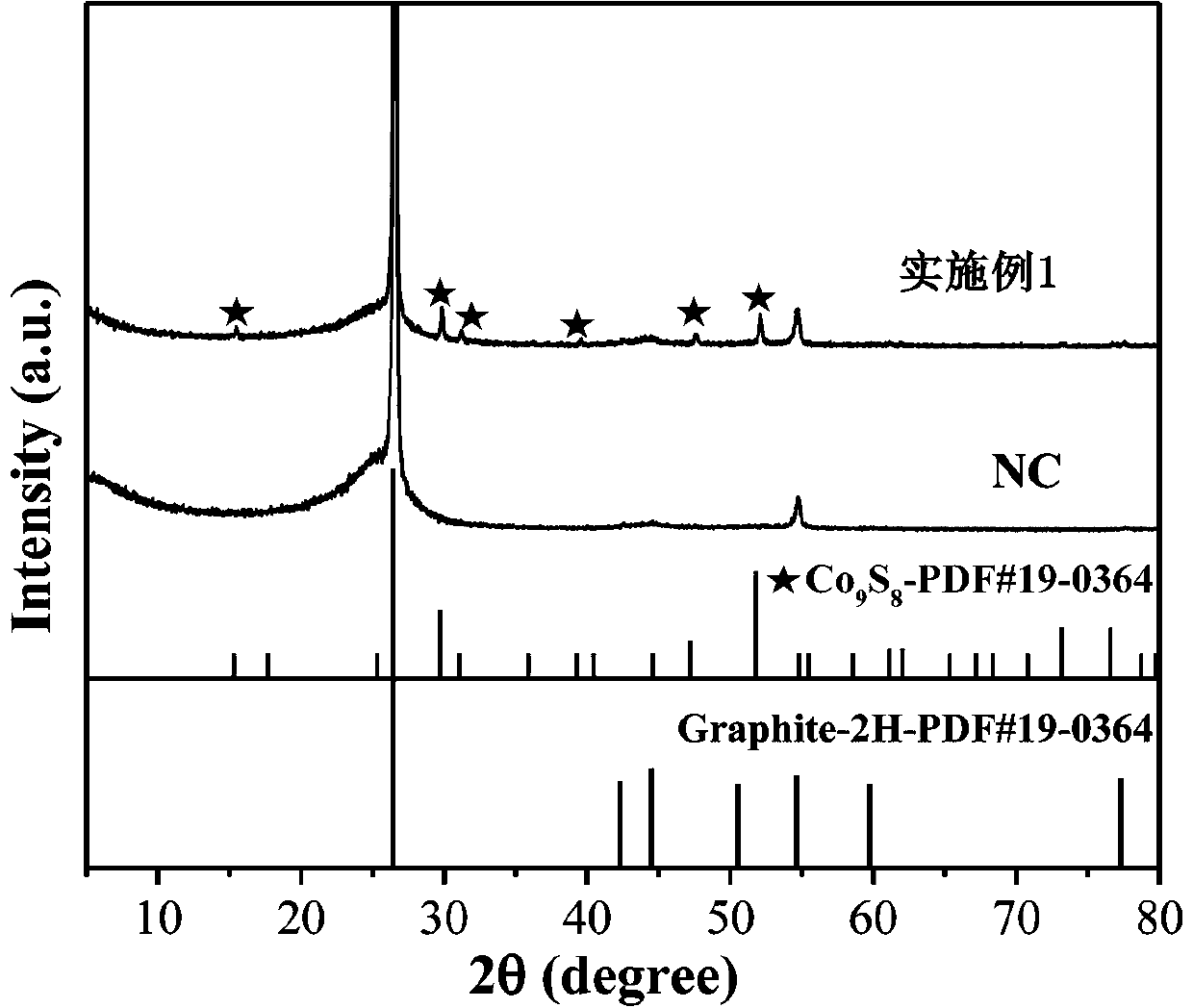

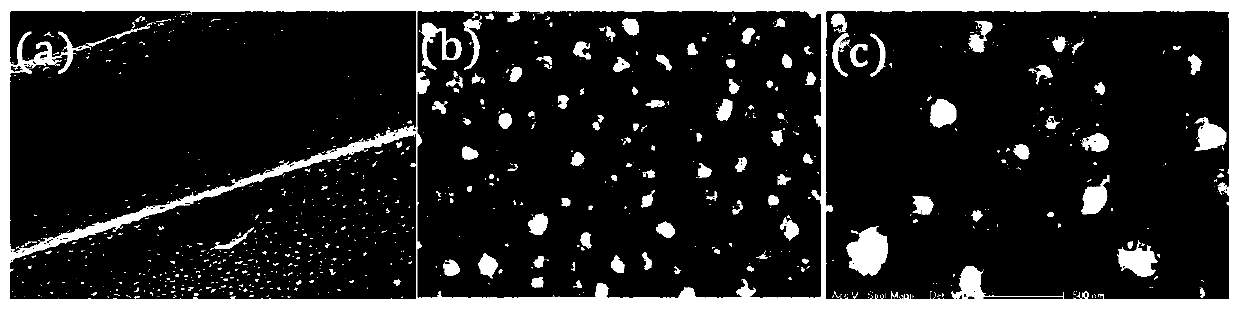

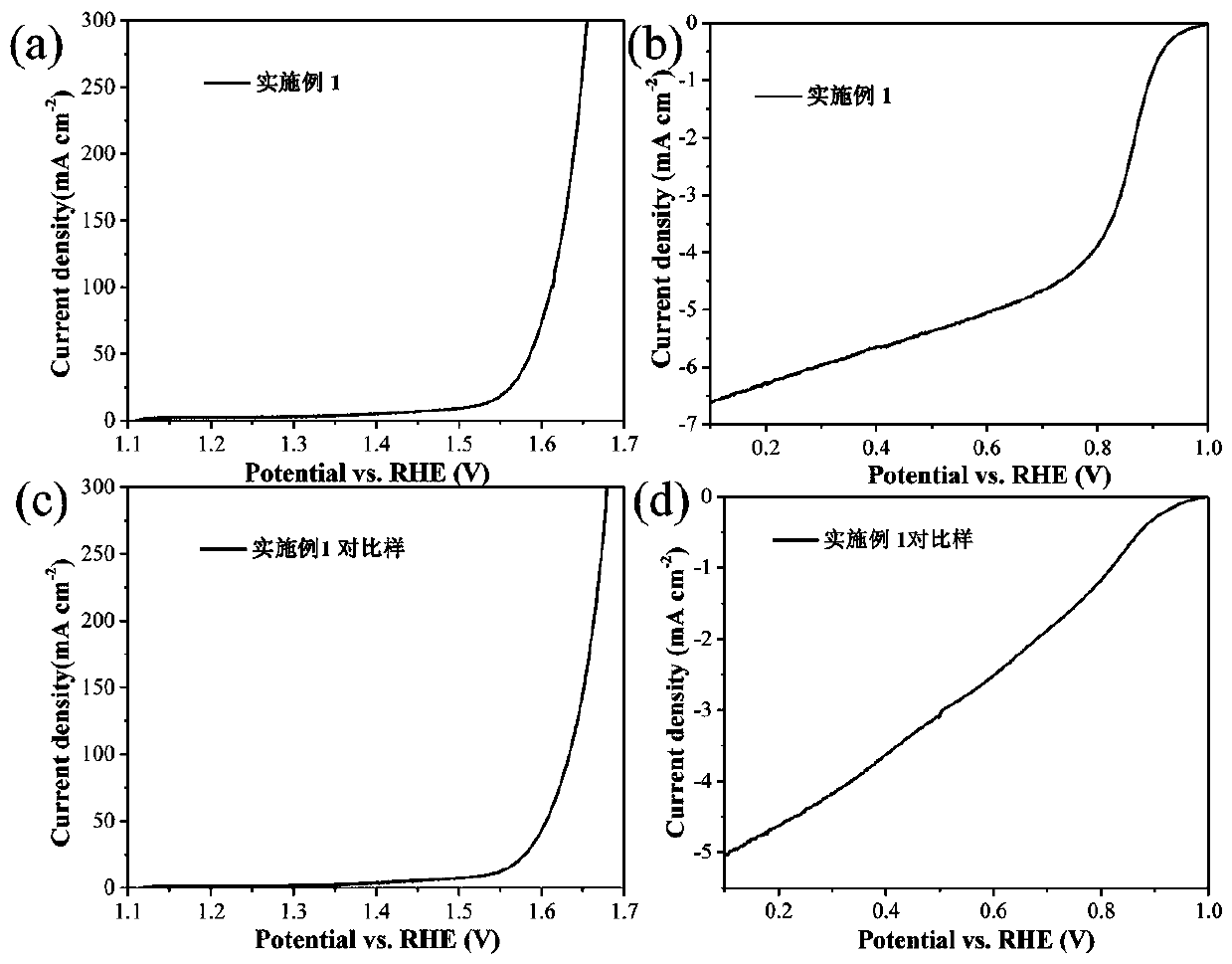

[0022] At room temperature, dissolve cobalt chloride hexahydrate, Tx-100, aniline and thiourea in 2.7 mL N,N-dimethylformamide solution, the concentration of cobalt chloride hexahydrate is 400 mM, Tx-100 The volume is 0.3 mL, the volume of aniline is 0.03 mL, and the concentration of thiourea is 1000 mM. Soak the carbon paper in the precursor solution for 30 minutes, take it out, dry it on a hot table at 80°C for 10 minutes, then apply the precursor solution evenly on the carbon paper, and then continue to dry for 30 minutes. Put the coated substrate into a tube furnace, react at 600°C for 1h under Ar flow, then continue to heat up to 900°C for 30min, and take it out after natural cooling to obtain cobalt sulfide-porous carbon. Subsequently, the above cobalt sulfide-porous carbon was reacted in 1 g of dicyandiamide at 600 °C for 1 h, and taken out after natural cooling to obtain the in-situ defect-modified Co 9 S 8 - Porous nitrogen-doped carbon electrodes.

[0023] figure...

Embodiment 2

[0030] At room temperature, dissolve cobalt chloride hexahydrate, Tx-100, aniline and thiourea in 2.5 mL N,N-dimethylformamide solution, the concentration of cobalt chloride hexahydrate is 400 mM, Tx-100 The volume is 0.5 mL, the volume of aniline is 0.05 mL, and the concentration of thiourea is 1000 mM. Soak the carbon paper in the precursor solution for 30 minutes, take it out, dry it on a hot table at 80°C for 10 minutes, then apply the precursor solution evenly on the carbon paper, and then continue to dry for 30 minutes. Put the coated substrate into a tube furnace, react at 600 °C for 1 h under Ar flow, then continue to heat up to 900 °C for 30 min, and take it out after natural cooling to obtain cobalt sulfide-porous carbon. Subsequently, the above cobalt sulfide-porous carbon was reacted in 1 g of dicyandiamide at 500 °C for 1 h, and taken out after natural cooling to obtain the in-situ defect-modified Co 9 S 8 - Porous nitrogen-doped carbon electrodes.

[0031] F...

Embodiment 3

[0033] At room temperature, dissolve cobalt chloride hexahydrate, Tx-100, aniline and thiourea in 2.0 mL N,N-dimethylformamide solution, the concentration of cobalt chloride hexahydrate is 400 mM, Tx-100 The volume is 1 mL, the amount of aniline is 0.03 mL, and the concentration of thiourea is 1000 mM. Soak the carbon paper in the precursor solution for 30 minutes, take it out, dry it on a hot table at 80°C for 10 minutes, then apply the precursor solution evenly on the carbon paper, and then continue to dry for 30 minutes. The coated substrate was put into a tube furnace, reacted at 600 °C for 1 h under Ar flow, then continued to heat up to 900 °C for 30 min, and took it out after natural cooling to obtain cobalt sulfide-porous carbon. Subsequently, the above cobalt sulfide-porous carbon was reacted in 1 g of dicyandiamide at 700 °C for 1 h, and taken out after natural cooling to obtain the in-situ defect-modified Co 9 S 8 - Porous nitrogen-doped carbon electrodes.

[0034...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com