Method for preparing Cu2ZnSn(S,Se)4 solar cell absorbing layer film by using mercaptan-based ink

A technology of solar cells and absorbing layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large-scale industrialization restrictions, inability to apply large-scale, toxic safety, etc., and achieve stable physical and chemical properties of raw materials, low cost, and low composition Precisely Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First, 0.341g CuCl 2 2H 2 O, 0.176g ZnCl 2 , 0.256g SnCl 2 2H 2 O, 0.19236g of sulfur powder, dissolved in 20ml of hexanethiol solvent in turn, fully stirred at room temperature until black ink.

[0039] Secondly, drop the ink solution on the soda-lime glass of the Mo-plated substrate, spin-coat at 800rmp, put it in an oven at 130°C, and dry it for 5min under non-blast conditions; then spin-coat and repeat the drying process 20 times , to obtain a prefabricated membrane with a certain thickness.

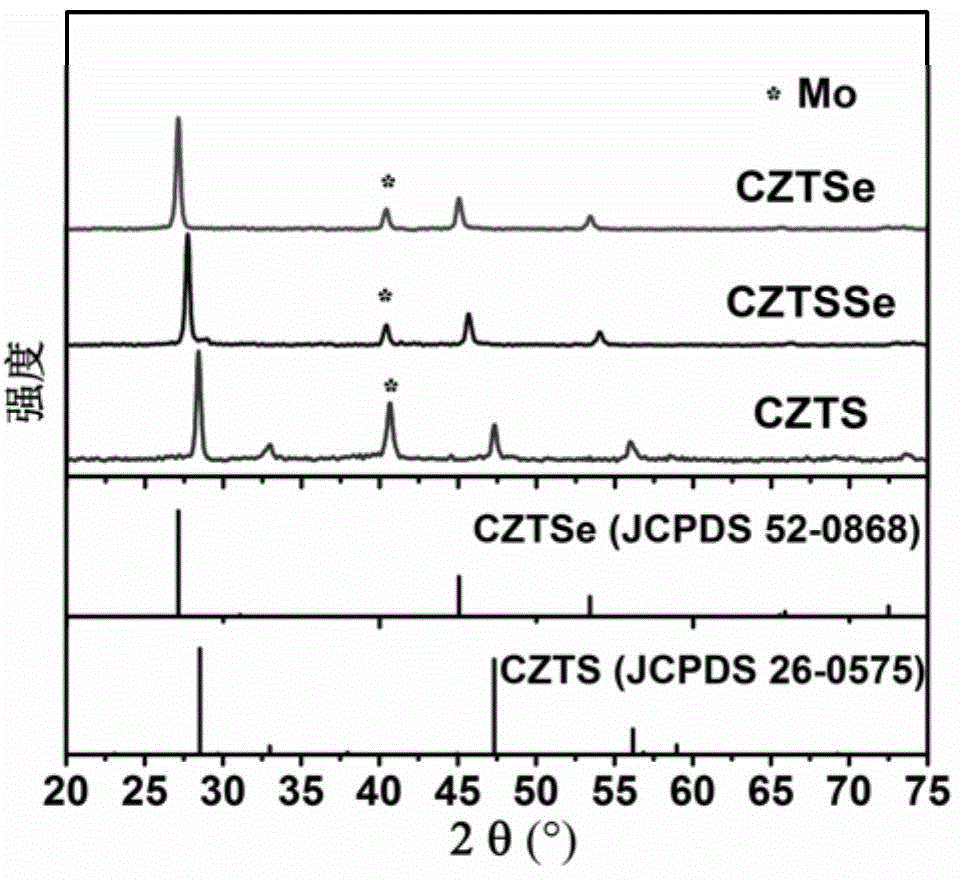

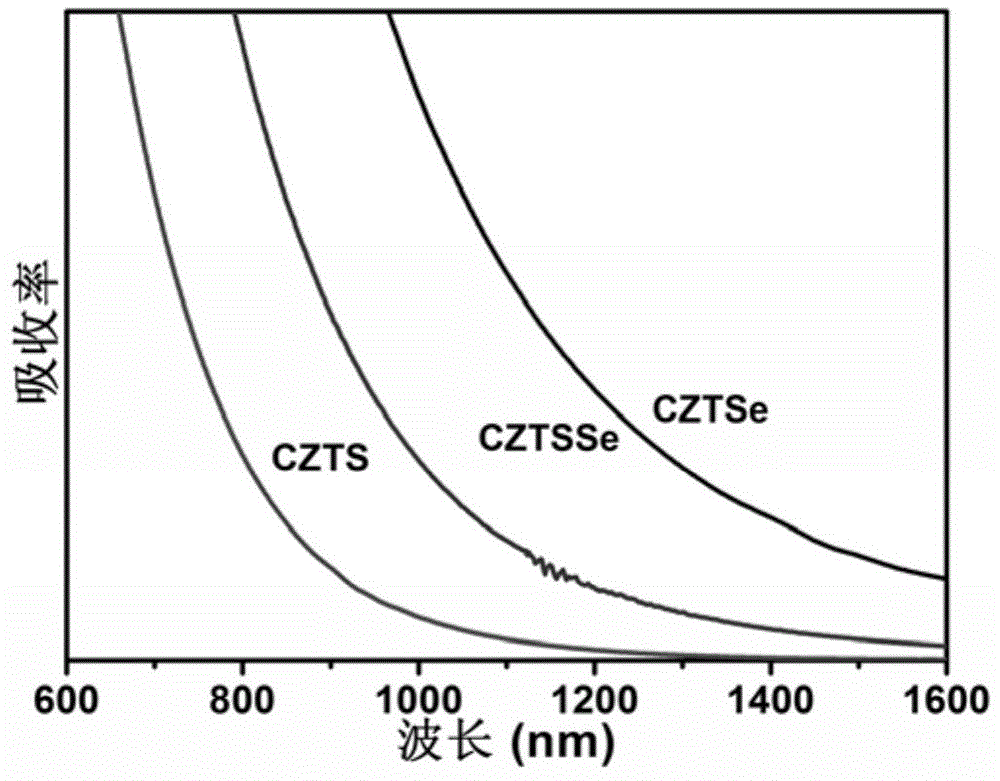

[0040] Finally, put a prefabricated film sample of a certain thickness and sulfur powder in a graphite box. The sulfur powder is placed in the groove under the film sample. The sulfur vapor can fill the entire graphite box through the slot hole, and the graphite box is placed in a tubular annealing furnace. , at N 2 The annealing treatment is carried out under the protection of the atmosphere, and the whole selenization annealing process is controlled by temperature prog...

Embodiment 2

[0043] First, 0.341g CuCl 2 2H 2 O, 0.176g ZnCl 2 , 0.256g SnCl 2 2H 2 O, 0.19236g of sulfur powder, dissolved in 20ml of hexanethiol solvent in turn, fully stirred at room temperature until black ink.

[0044] Secondly, drop the ink solution on the soda-lime glass of the Mo-plated substrate, spin-coat at 800rmp, put it in an oven at 130°C, and dry it for 5min under non-blast conditions; then spin-coat and repeat the drying process 20 times , to obtain a prefabricated membrane with a certain thickness.

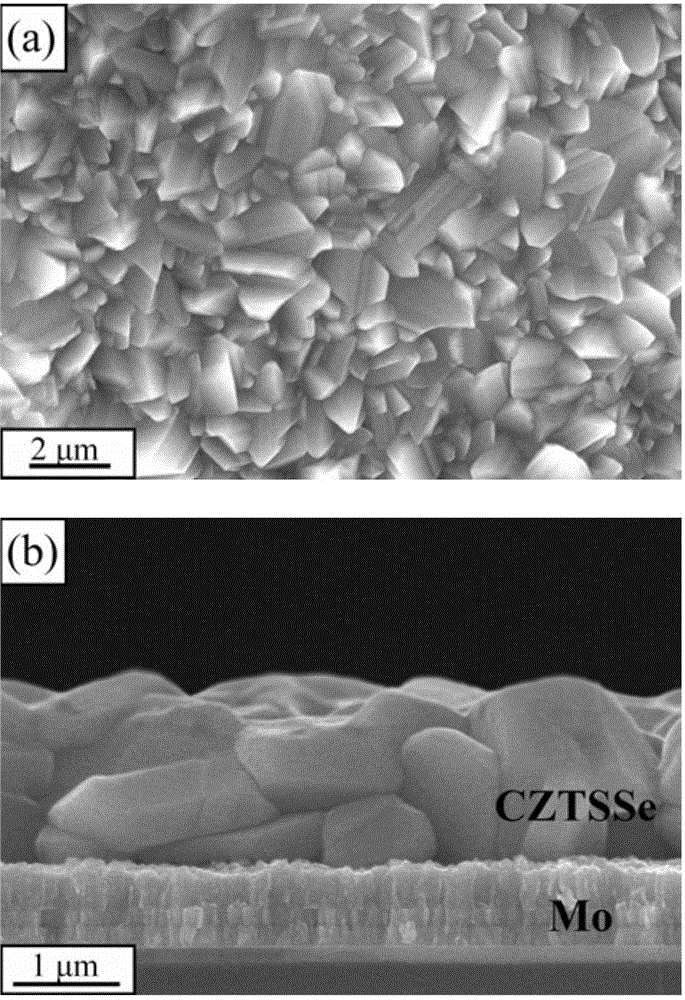

[0045] Finally, a prefabricated film sample of a certain thickness and sulfur powder / selenium powder are mixed and placed in a self-made graphite box. The sulfur and selenium powder are placed in the groove under the film sample, and the sulfur / selenium vapor can fill the entire graphite box through the slot. Place the graphite box in the tube annealing furnace, under N 2 The annealing treatment is carried out under the protection of the atmosphere, and the temperature p...

Embodiment 3

[0048] First, 0.341g CuCl 2 2H 2 O, 0.176g ZnCl 2 , 0.256g SnCl 2 2H 2 O, 0.19236g of sulfur powder, dissolved in 20ml of hexanethiol solvent in turn, fully stirred at room temperature until black ink.

[0049] Secondly, drop the ink solution on the soda-lime glass of the Mo-plated substrate, spin-coat at 800rmp, put it in an oven at 130°C, and dry it for 5min under non-blast conditions; then spin-coat and repeat the drying process 20 times , to obtain a prefabricated membrane with a certain thickness.

[0050] Finally, put a prefabricated film sample of a certain thickness and selenium powder in the graphite box, the selenium powder is placed in the groove under the film sample, the selenium vapor can fill the entire graphite box through the slot hole, and the graphite box is placed in the tubular annealing furnace , at N 2 The annealing treatment is carried out under the protection of the atmosphere, and the temperature program is used to control the entire selenizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com