A method and device for treating organic sewage

A technology of organic sewage and treatment method, which is applied in the field of sewage treatment equipment and the treatment of refractory organic sewage, can solve the problems of large workload of replacing fillers, large amount of sludge, and reduced effect, so as to reduce treatment costs and reduce operating costs. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

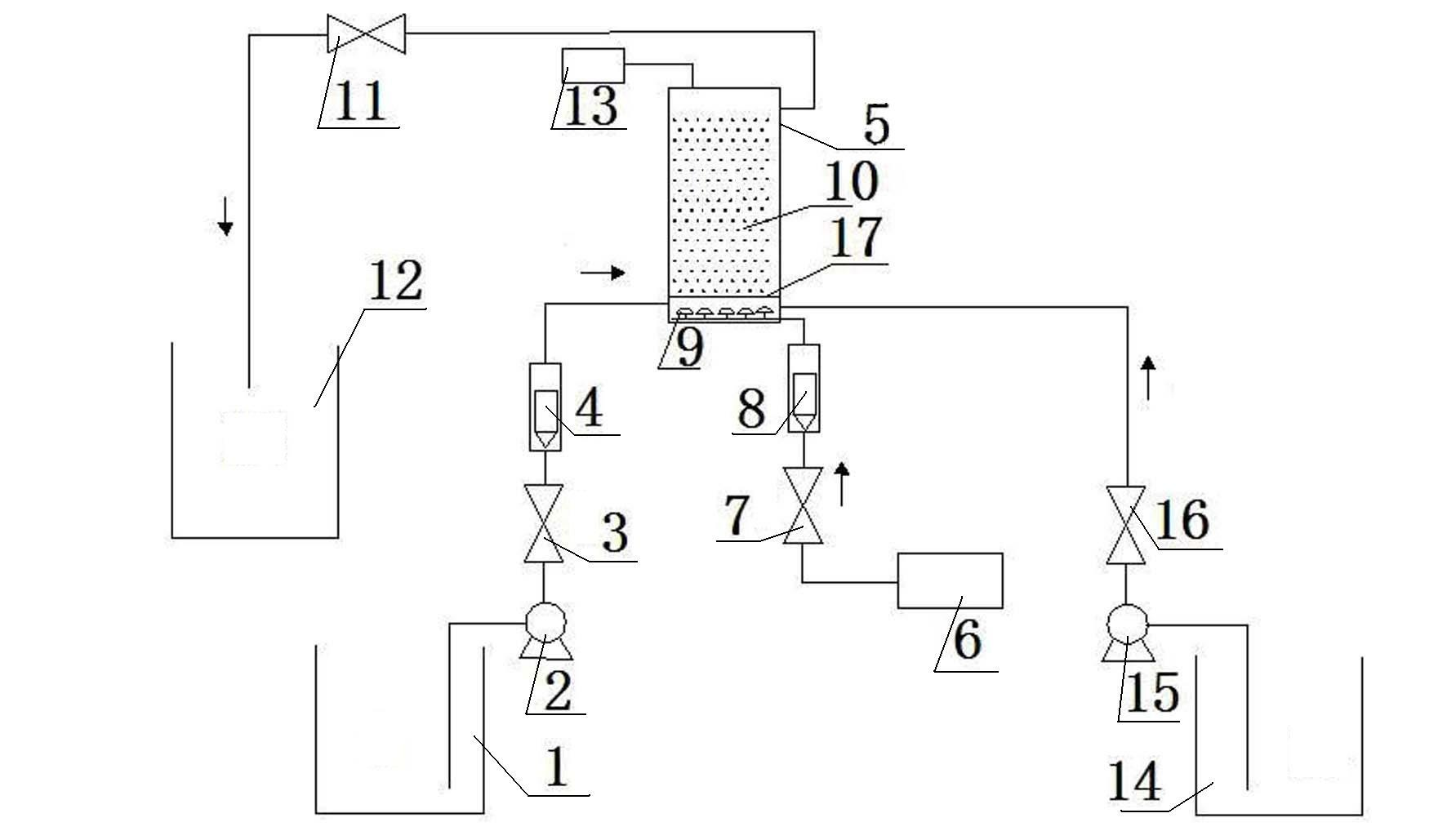

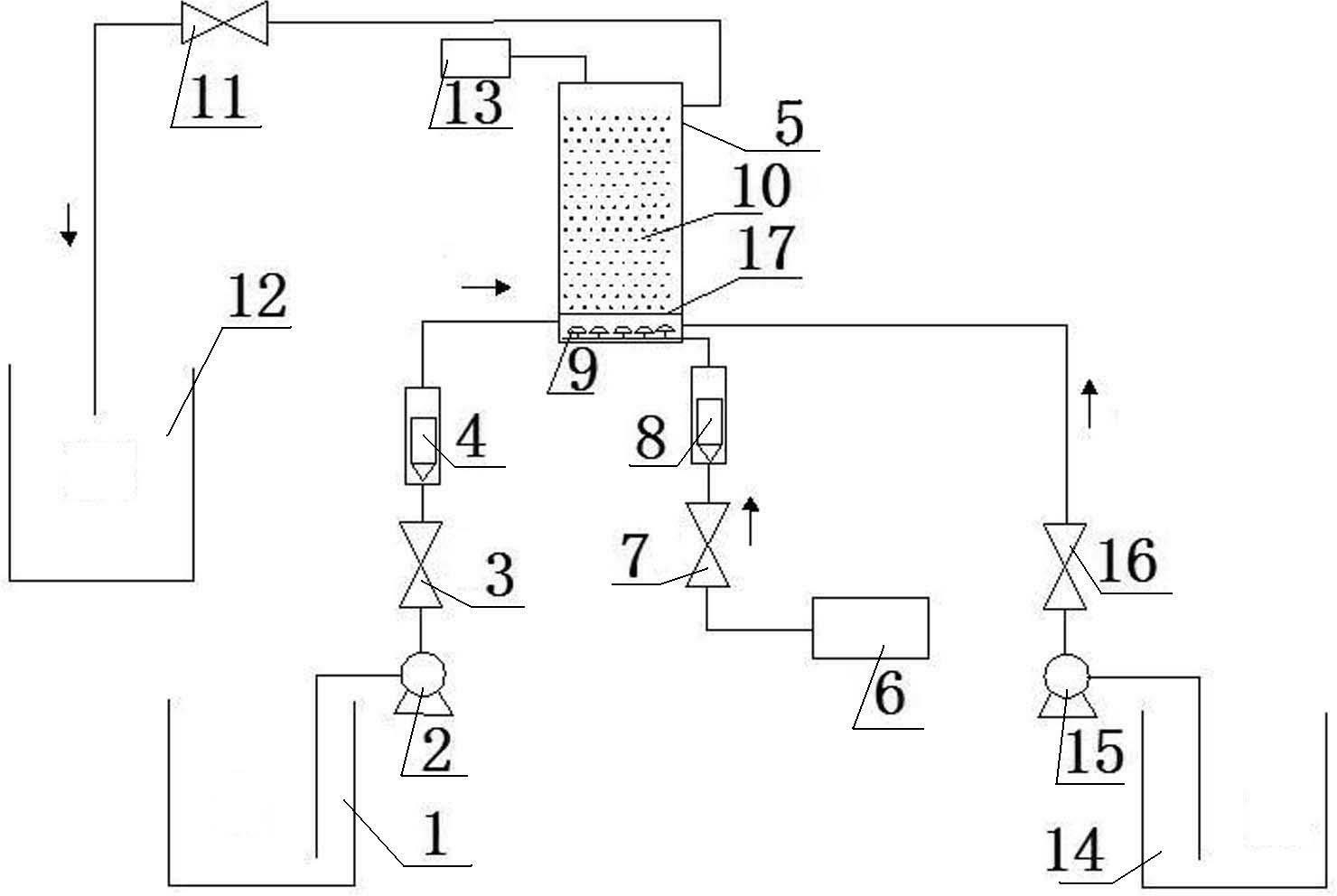

Method used

Image

Examples

Embodiment 1

[0029] The sewage is landfill leachate sewage, the mass ratio of iron to carbon is 0.5, the rate of ozone introduction is 6g / h, the mass concentration is 1% and the amount of hydrogen peroxide is 10ml / h, and the size of the reactor is Ф100mm×1500mm. The volume of the device is 15L. After 30 days of continuous operation, the decolorization rate of landfill leachate sewage reaches 96%, and the COD removal rate reaches 75%.

Embodiment 2

[0031] Described sewage is printing and dyeing organic sewage, and COD is 4000mg / L, and iron-carbon mass ratio is 0.1, and the rate that ozone feeds is 8g / h, and mass concentration is that the add-on of 2% sodium hypochlorite solution is 20ml / h, and reactor size It is Ф100mm×1500mm, and the reactor volume is 15L. After 30 days of continuous operation, the decolorization rate of the device for printing and dyeing organic sewage reaches 98%, and the COD of the discharged treatment solution is 80mg / L.

Embodiment 3

[0033] Described sewage is papermaking black liquor sewage, COD is 15000mg / L, chromaticity 20000 times, iron-carbon mass ratio is 0.3, the rate of ozone feed is 9g / h, and the mass concentration is that the addition amount of 3% hydrogen peroxide solution is 10ml / h, the size of the reactor is Ф100mm×1500mm, and the reactor volume is 15L. After 40 days of continuous operation, the decolorization rate of the device to papermaking black liquor reaches 98%, and the COD removal rate is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com